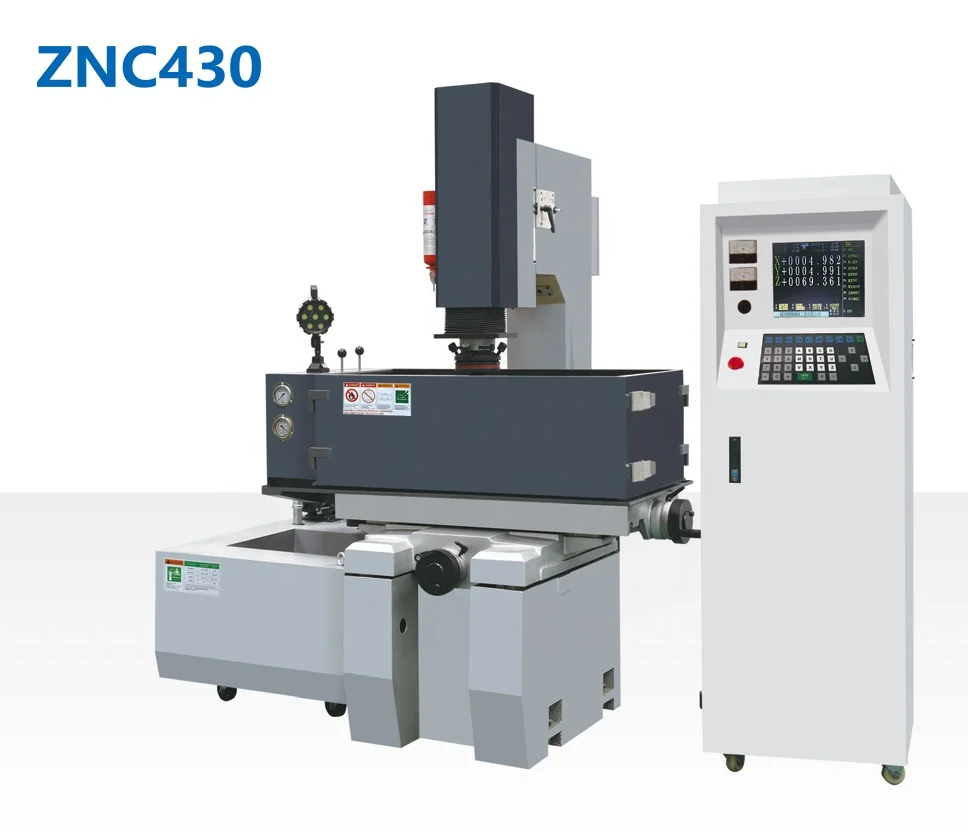

EDM сверлильный станок станки

- Категория: >>>

- Поставщик: Taizhou Taisen Electromechanical Co. Ltd.

Сохранить в закладки 1600241637172:

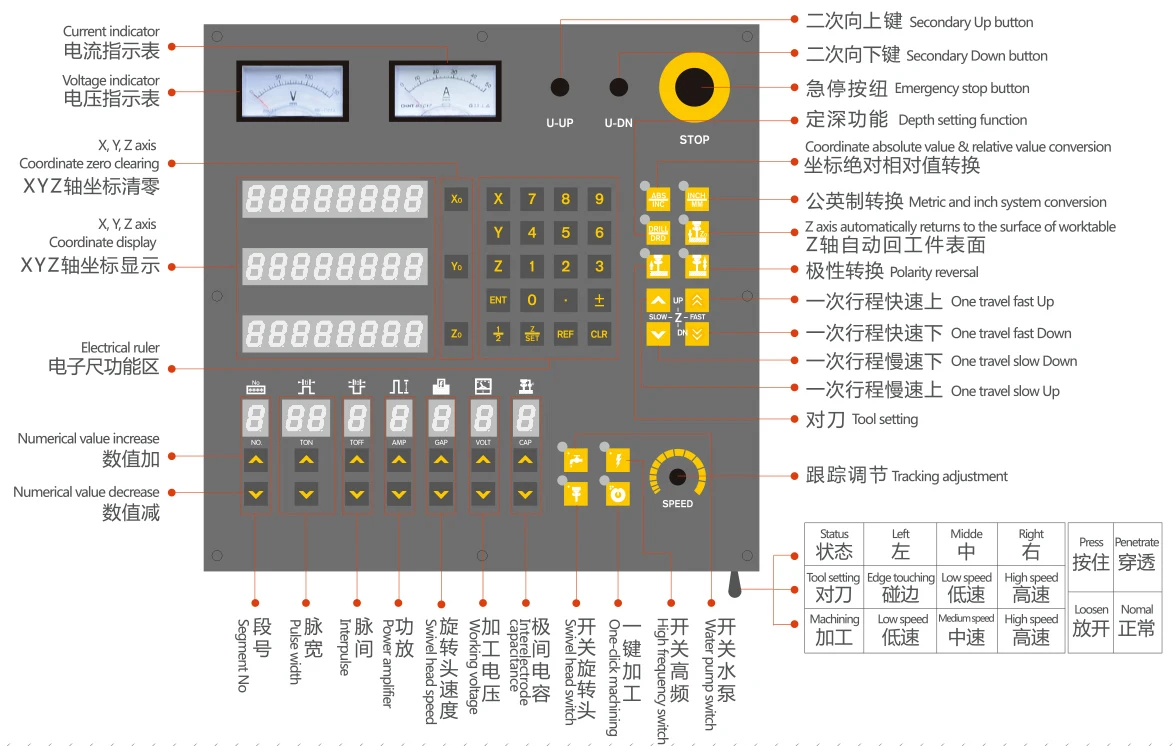

Описание и отзывы

Характеристики

Advantages of DZ430A/B/C:

1.Can drill deep hole with diameters 0.3mm ~ 3mm (the depth-diameter ratio is 300:1).

2.The speed of drilling hole is 30mm~60mm depth per minute (it is different for different material).

3.Can drill wire-cut starting hole, filter hole, jet hole, gas hole, group holes and hole of super depth etc.

4.Can drill small holes on the various conductive materials, even semiconductor material, especially stainless steel, chilled steel, copper, aluminum, and hard alloy etc.

5.Can easily erode the drill and screw tap etc. which is broken in the workpiece and not destroy the screw thread of the holes.

6.The working water can be normal water or saponification fluid and no pollution is brought.

7.The operation is easy and convenient

8.X, Y, Z three axes digital display with scale.

Features:

1.The maximum stroke of the Z axis is 380mm, which can hold 500mm long electrodes, and the waste of the electrode tube is minimized to about 100mm. The ultra-low wear circuit design is used to greatly improve the use ratio of the electrode tube.

2. The Z axis adopts micro stepping motor to realize fast feed speed, the whole stroke only takes about 10 seconds, greatly reduced the waiting time and improved the efficiency. The W axis, i.e. stroke of machine head, is manual control with fast speed.

3.Patented rotating head: the integrated design of the rotating head and the motor, use tungsten steel wear-resistant plate and multiple waterproof structures. The taper sleeve is used to connect with the chuck to ensure the concentricity of the chuck rotation.

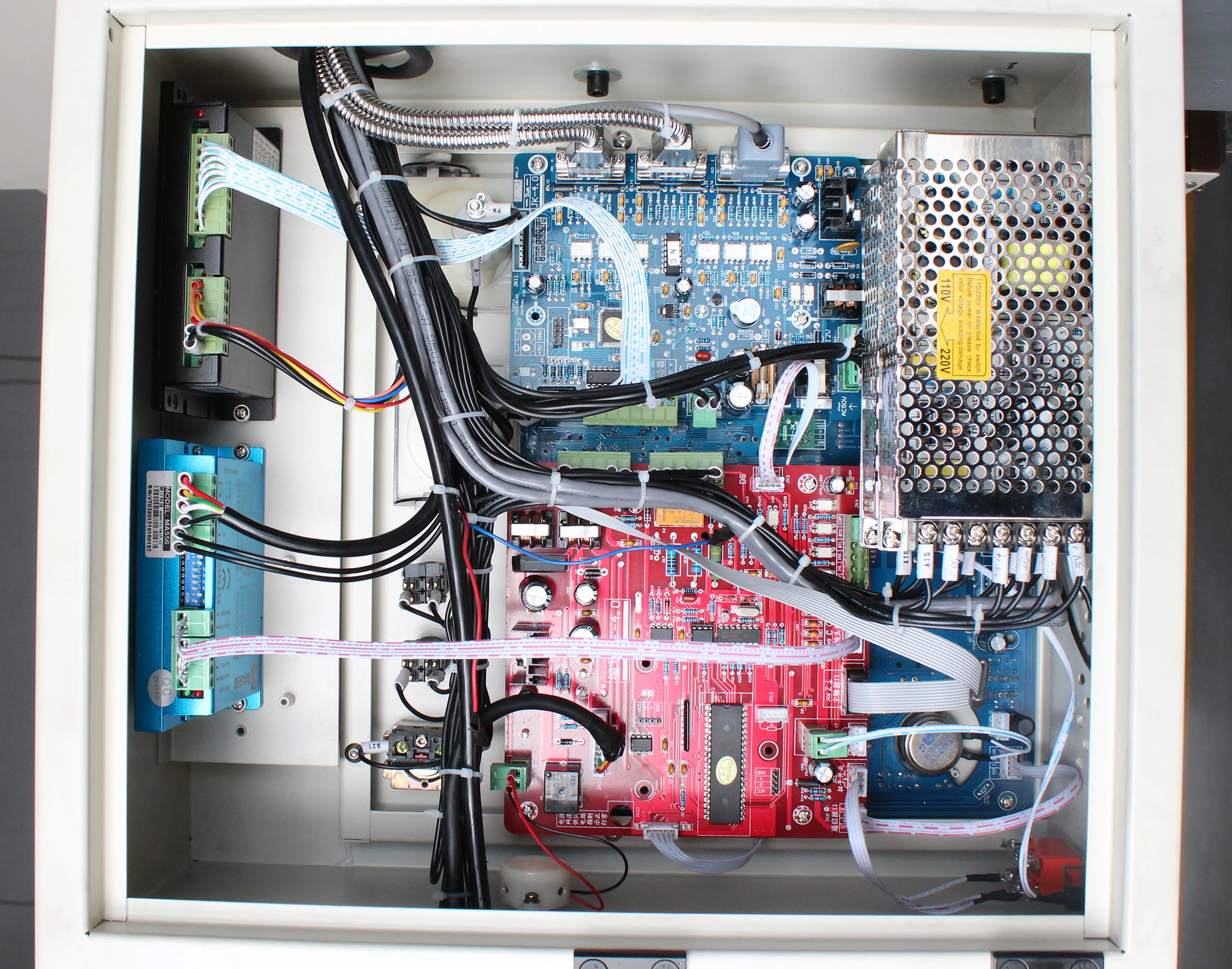

4.Own developed control system: one-key machining, centering function, fixed end surface function, expert database, digital sampling, adaptive servo tracking, penetration function, flexible machining, high-speed machining, surface protection, spindle automatically goes back to the workpiece surface. It is suitable for the processing of fine holes of electrode copper tubes of Φ0.3 to Φ3.0, the processing of ultra-thick workpieces with a thickness of less than 300mm, and the processing of super-hard and special materials such as tungsten steel, aluminum, and AK80.

Specification:

Item | Technical terms | DZ430C | DZ430B | DZ430A |

1 | Electrode diameter (mm) | Φ0.3-Φ3.0 | Φ0.2-Φ3.0 | Φ0.1-Φ3.0 |

2 | Machine head travel (mm) | 280 | 280 | 280 |

3 | Spindle servo travel (mm) | 380 | 380 | 380 |

4 | Max. speed of spindle (mm) | 1500 | 1500 | 1500 |

5 | Rotation speed of the spindle (rpm) | 0-200 adjustable | 0-200 adjustable | 0-200 adjustable |

6 | Worktable size (mm) | 440×320 | 440×320 | 440×320 |

7 | X×Y travel(mm) | 400×300 | 400×300 | 400×300 |

8 | Max. Distance from guide to worktable(mm) | ≥300 |

≥300 |

≥300 |

9 | Max. working current (A) | 30 | 30 | 30 |

10 | Max. input power (KW) | 4.0 | 4.0 | 4.0 |

11 | Power supply | 3 phase 380V/50Hz | 3 phase 380V/50Hz | 3 phase 380V/50Hz |

12 | Digital display type | X, Y, Z | X, Y, Z | X, Y, Z |

13 | Max. working liquid pressure (Mpa) | 8 |

12 |

12/8 |

14 | Working liquid supply device | Electrical plunger pump |

Pneumatic pump | Double pumps (electrical pump + pneumatic pump) |

15 | Max. worktable load(kg) | 380 | 380 | 380 |

16 | Overall dimension of machine(W×L×H) | 1000×1000×2000 |

1000×1000×2000 |

1000×1000×2000 |

17 | Machine weight(kg) | 700 | 700 | 700 |

18 | X, Y, Z configuration | X, Y, Z precise ball screw | X, Y, Z precise ball screw | X, Y, Z precise ball screw |

X, Y, Z axis Taiwan made linear guideway | X, Y, Z axis Taiwan made linear guideway | X, Y, Z axis Taiwan made linear guideway | ||

Z, W axis motorized; X, Y axis manual | Z, W axis motorized; X, Y axis manual | Z, W axis motorized; X, Y axis manual |

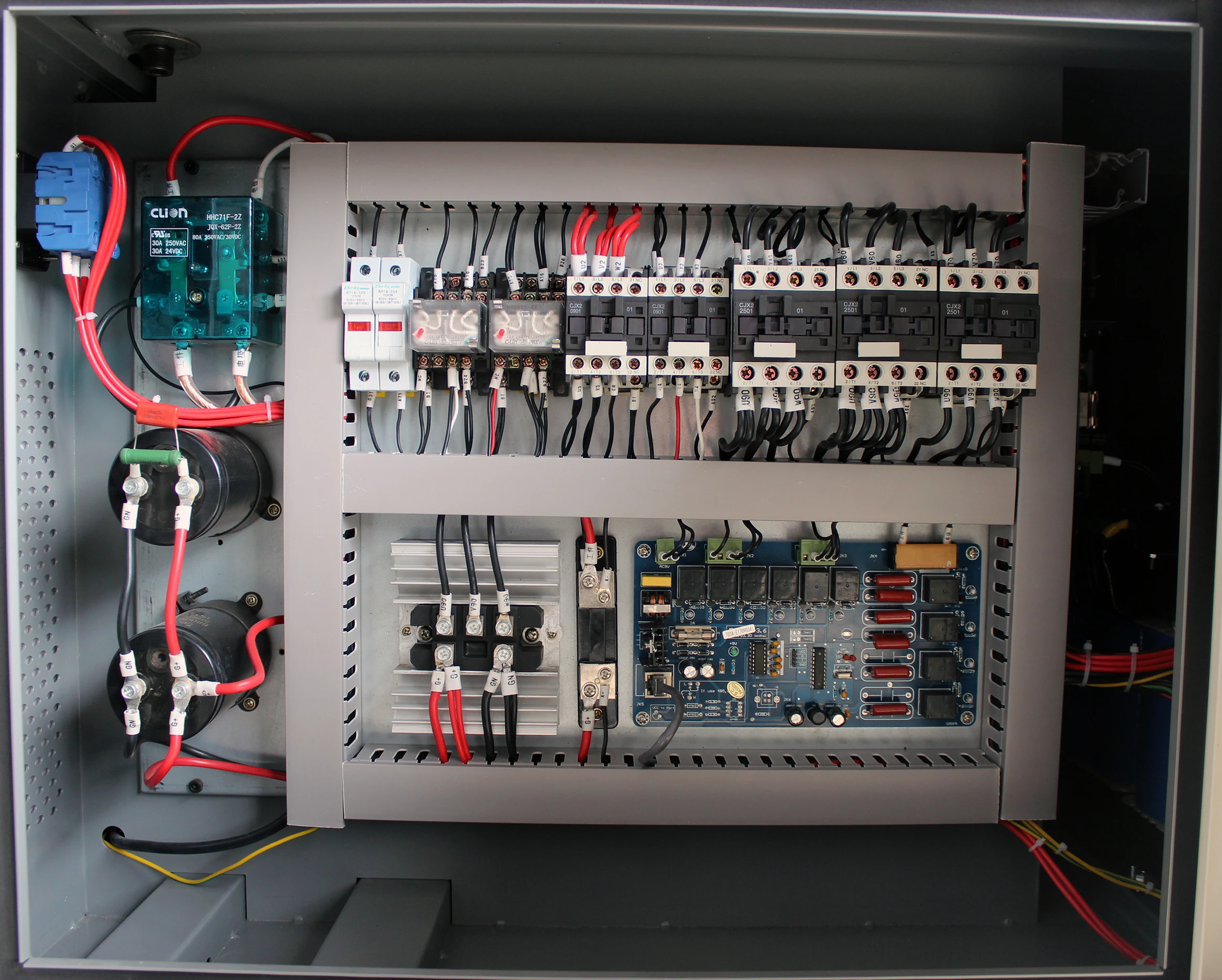

Professional Manufacturing Plant:

Похожие товары

Пользовательский логотип Helios XD3 Новый Fantech двойной режим Проводная Беспроводная Pixart 3335 легкая RGB макрооптовая продажа игровая мышь

Китайская оптовая продажа, домашний и свадебный художественный декор, Золотая Пылезащитная поверхность, большая цветная стеклянная ваза для цветов

Головка цилиндра двигателя EN55/XD3 для DAF VA400/VD400/VH400/VS40

EDM машины ZNC EDM машины цена

Китайский поставщик, услуги Edm, сверлильный станок с искрящей эрозией, цена

EDM машина ZNC EDM машина цена

CNC проволочно-вырезной станок EDM машины ANT-WS 6D/8D профессиональный поставщик из Китая

Новые поступления

Новинки товаров от производителей по оптовым ценам