Высококачественная Планетарная шлифовальная машина для бетона новый дизайн алмазная

- Категория: >>>

- Поставщик: Guangdong TG Machinery Industrial Co. Ltd.

Сохранить в закладки 1600370542967:

Описание и отзывы

Характеристики

Product Description

Specification

item | value |

Applicable Industries | Hotels, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company |

After Warranty Service | Video technical support, Online support |

Local Service Location | Viet Nam, Indonesia |

Showroom Location | Viet Nam, Indonesia |

Video outgoing-inspection | Provided |

Machinery Test Report | Provided |

Marketing Type | New Product 2020 |

Warranty of core components | 1 Year |

Core Components | Bearing, Gearbox, Motor |

Condition | New |

Automatic Grade | Automatic |

Place of Origin | China |

Guangdong | |

Brand Name | TG |

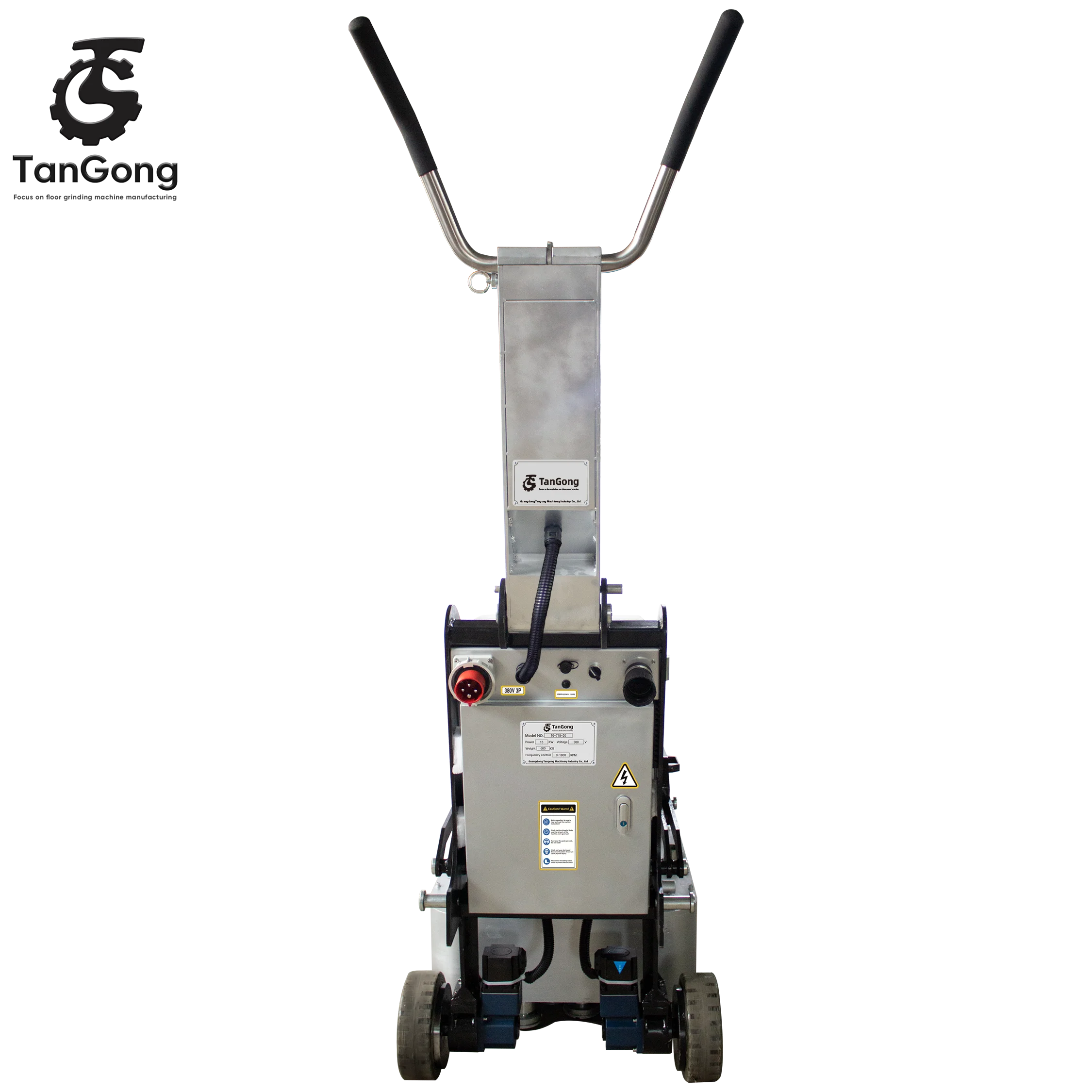

Voltage | 380V |

Power | 18.5KW |

Dimension(L*W*H) | 140*90*125cm |

Weight | 680kg |

Certification | ce, ISO |

Warranty | 1 Year |

Video technical support, Online support | |

UNIQUE SELLING POINT | High operating efficiency |

Engine Brand | WEG |

Product name | TG718-20 |

Application | Concrete Marble Terrazzo Granite Stone Floor |

Function | Surface Grinding Polishing |

Working Width | 718mm |

Speed | 0-1800 Rpm |

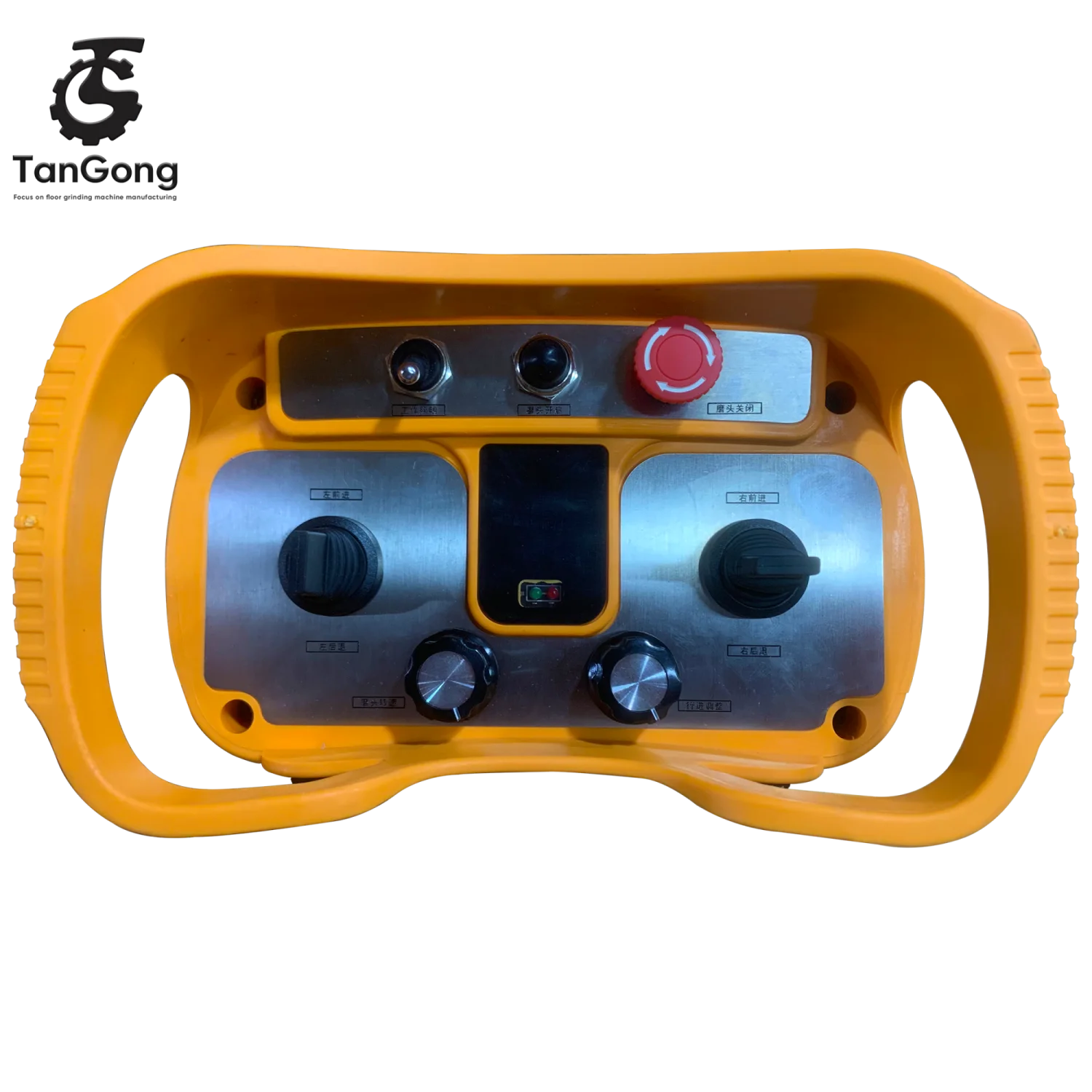

Driving method | remote control |

Inverter | 22KW |

Elector Motor | WEG |

Grinding head | 20 pieces |

Plate Type | Multi-Funtion |

Packing & Delivery

Each ground grinder is packed in standard wooden cases, which is suitable for sea or air transportation and meets the

transportation standards

transportation standards

Company Profile

Guangdong Tangong Machinery Industry Co.,Ltd. is a comprehensive high-tech enterprise specializing in research and

development,production,sales,engineering design and construction of floor materials.

Our company has advanced production and construction equipment,a complete scientific quality management system,high quality and enthusiastic after-sales service team.

Our factory offers responsible and practical machinery solutions to retailers,agents and wholesalers.More than 10 years’

experienced technicians and advanced equipment allow us to ensure superior quality and high efficiency.

Quality and service is our culture.

development,production,sales,engineering design and construction of floor materials.

Our company has advanced production and construction equipment,a complete scientific quality management system,high quality and enthusiastic after-sales service team.

Our factory offers responsible and practical machinery solutions to retailers,agents and wholesalers.More than 10 years’

experienced technicians and advanced equipment allow us to ensure superior quality and high efficiency.

Quality and service is our culture.

Carmen Lee

Marketing Manager

You can contact me to provide you with more information

Looking forward to cooperating with you

FAQ

1.Q:Does your factory accept custom-made?

A:Yes, we can provide OEM service to customer. Surely, Including different color, motor, inverter etc. We also can mark your own logo and brand on the machine. Any new products you want us to produce for you, just send us your drawing or sample, we will produce the same one. We will not sell this kind of products to other customers only if we get your permission.

A:Yes, we can provide OEM service to customer. Surely, Including different color, motor, inverter etc. We also can mark your own logo and brand on the machine. Any new products you want us to produce for you, just send us your drawing or sample, we will produce the same one. We will not sell this kind of products to other customers only if we get your permission.

2.Q:How to know your machines' quality before we order the product?

A:Firstly,we have our own factory ,CNC workshop the Core Technology controlled by ourselves.More and more people in the world to use Chinese brand product because the high quality and very good competitive price, we are specialized in producing floor grinding machines many year.

Secondly, Our products already sold to many countries around the world, and in 38 countries/area around the China we have office/agent. You can visit our factory at any time.

Thirdly,our is a National High-Tech Enterprise .

Fourthly , the duration for quality warranty of motor and inverter,gear for ONE year. We promise to help maintenance our machine forever. If exceed guarantee time, spare parts broken due to long time using, the charge of the new parts

and express will be paid by customer, and we will send you steps or video to help you repair. You can contact with us at any time, our after-sale service team 24 hours waiting for service for you.

Anyway, confirming our products quality, we welcome you to visit our factory at any time or buy a order to test the quality

A:Firstly,we have our own factory ,CNC workshop the Core Technology controlled by ourselves.More and more people in the world to use Chinese brand product because the high quality and very good competitive price, we are specialized in producing floor grinding machines many year.

Secondly, Our products already sold to many countries around the world, and in 38 countries/area around the China we have office/agent. You can visit our factory at any time.

Thirdly,our is a National High-Tech Enterprise .

Fourthly , the duration for quality warranty of motor and inverter,gear for ONE year. We promise to help maintenance our machine forever. If exceed guarantee time, spare parts broken due to long time using, the charge of the new parts

and express will be paid by customer, and we will send you steps or video to help you repair. You can contact with us at any time, our after-sale service team 24 hours waiting for service for you.

Anyway, confirming our products quality, we welcome you to visit our factory at any time or buy a order to test the quality

3. Q:What shall I do to start concrete floor polish?

A:We recommend a complete surface preparation system including: a concrete grinding machines equipment, vacuum systems, right diamond tooling, chemicals and dyes(optional).It is also important to receive proper training to ensure that your projects are completed in a professional, timely and cost effective manner.

A:We recommend a complete surface preparation system including: a concrete grinding machines equipment, vacuum systems, right diamond tooling, chemicals and dyes(optional).It is also important to receive proper training to ensure that your projects are completed in a professional, timely and cost effective manner.

4.Q: Are you real manufacturer ?How can I visit your factory?

A: Yes of course, we are the manufacturer! We warmly welcome clients to visit our factory to inspect our produce process at anytime.Our factory is located in Guangzhou city, China.

A: Yes of course, we are the manufacturer! We warmly welcome clients to visit our factory to inspect our produce process at anytime.Our factory is located in Guangzhou city, China.

5.Q: Your floor grinding machines are all gear driven?

A: All of our floor grinding machine are gear driven. The machine with gear driven is more powerful and effective than belt

driven,for maintenance only need change gear oil.

A: All of our floor grinding machine are gear driven. The machine with gear driven is more powerful and effective than belt

driven,for maintenance only need change gear oil.

6. Q:Why choose gear driven floor grinder?

A:Ourengineers found most grinders are not high efficiency of use belt-driven system. And tension between belts waste a lot of power in practices.In addition,belt-driving cannot control grinding precision very well in that belts will slip when friction

with floor is too big.This will lead to unstable speed of grinding heads or belt tension can slow down spinning of grinding

heads significantly. The good news is that gear-driving system can solve this problem for you.The gear-driving planetary

rotating system in Grinding machines had passed 13000 hours of test successfully. So our gear-driving floor grinder is more reliable.

A:Ourengineers found most grinders are not high efficiency of use belt-driven system. And tension between belts waste a lot of power in practices.In addition,belt-driving cannot control grinding precision very well in that belts will slip when friction

with floor is too big.This will lead to unstable speed of grinding heads or belt tension can slow down spinning of grinding

heads significantly. The good news is that gear-driving system can solve this problem for you.The gear-driving planetary

rotating system in Grinding machines had passed 13000 hours of test successfully. So our gear-driving floor grinder is more reliable.

7.Q:What are the advantages of your products compared with other products?

A:Our products are excellent in terms of productivity, handling, reliability and construction results.Cutting and aluminum

casing gear box make the machine parts more accurate. We make the machine, polishing pads and chemical, so we can offer you the full set of product you need for the floor.

A:Our products are excellent in terms of productivity, handling, reliability and construction results.Cutting and aluminum

casing gear box make the machine parts more accurate. We make the machine, polishing pads and chemical, so we can offer you the full set of product you need for the floor.

8.Q: How long is your delivery time?

A: It is according to the model and quantity.

Generally it is 3-5 days if the machines are in stock.

It will be 15-30 days if you want to customize the machines.

A: It is according to the model and quantity.

Generally it is 3-5 days if the machines are in stock.

It will be 15-30 days if you want to customize the machines.

9.Q: Does your gear quality better than those from other company?

A: Yes, we make the gear our own. Our gear is skewed tooth and being heat treatment processed which guarantee stable performance and long life time. But many company don’t use such gear because this gear need high-precision process. We make the gears with CNC machine.

A: Yes, we make the gear our own. Our gear is skewed tooth and being heat treatment processed which guarantee stable performance and long life time. But many company don’t use such gear because this gear need high-precision process. We make the gears with CNC machine.

10.Q: What parts are usually needed for replacements?

Resin grinding disc, alloy cutter head, dust belt and conversion head.

Похожие товары

Массажер HUIFAN с подогревом для пожилых людей тепловой пояс массажа шеи и плеч разминающий

12,50 $ - 15,00 $

Мешок фильтра PPS для промышленного смога, мешок фильтра

Хирургические ножницы с золотистой ручкой, высококачественные стоматологические инструменты

Опорный подшипник для синхронного винт jack система подъема

11,00 $ - 55,00 $

Светодиодная лампа накаливания G125 с надписью «Hello Love Home Dream inside» 4 Вт 2200 к регулируемой яркостью прозрачное и Золотое

3,20 $ - 4,00 $

1000L дистилляционное оборудование спиртовой дистиллятор установка для дистилляции

Высококачественная женская зимняя одежда 2021, укороченная куртка большого размера из искусственного лисьего меха для женщин, Пузырьковые куртки

23,80 $ - 25,80 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $