Катодная защита катодный анод цинковый для кораблей корпус сваечный магниевый алюминиевый

- Категория: >>>

- Поставщик: Tianjin Elegant Technology Co. Ltd.

Сохранить в закладки 1600376432459:

Описание и отзывы

Характеристики

We are professional manufacturer and has more than twenty years experience in anti corrosion industry. Our main products includes:

· Sacrificial Magnesium casting & Extruded Anode, Magnesium Ribbon anode

· Sacrificial Aluminum Anode

· Sacrificial Zinc anode, Zinc Ribbon Anode,

· High Silicon Cast-Iron Anode

· Epoxy Coated Steel Reinforcing Bar

· Ant-corrosion Tapes

The size, weight, Chemical compositions and shape are available upon request.

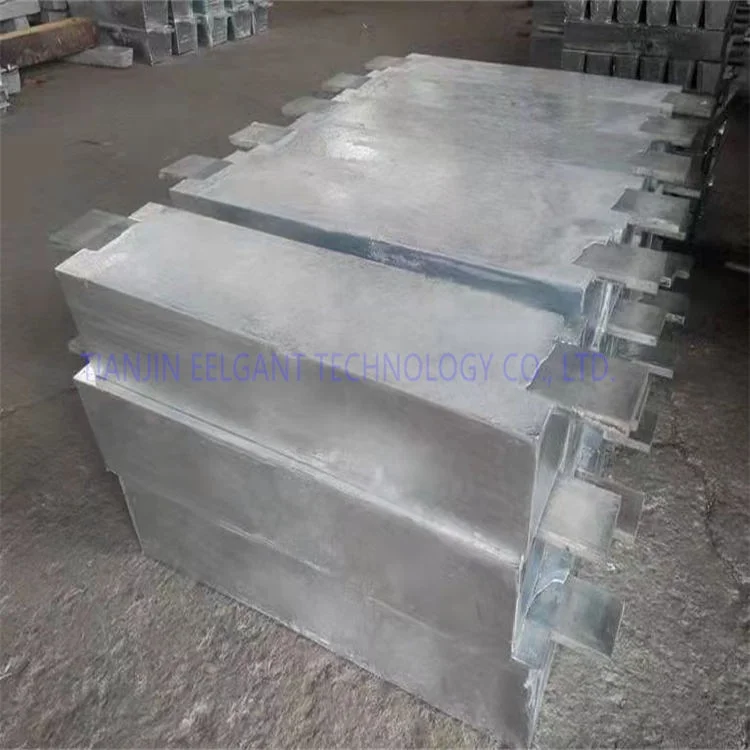

Zinc alloy sacrificial anode

Zinc alloy sacrificial anode

The cathodic protection method of zinc anode is to connect a metal or alloy that is more likely to lose electrons to protect steel equipment. For example: the protection of steel gates, some use this method. It is a more active metal, such as zinc, which is attached to the steel gate. In this way, when galvanic corrosion occurs, the metal that is more active than iron is corroded, and iron is protected. Usually, a certain amount of zinc blocks are installed at the stern of the ship and below the waterline of the hull to prevent the hull from corroding. This is the method used.

Product features: low self-solubility, high current efficiency, wide application range.

At present, electrochemical protection is not only used to protect steel equipment in sea water or rivers, but also to prevent corrosion of cables, petroleum pipelines, underground equipment, and chemical equipment. Aluminum alloy sacrificial anodes are suitable for cathodic protection of metal corrosion protection for ships, mechanical equipment, marine engineering and seaport facilities in seawater media, pipelines, cables and other facilities in sea mud, and soil media with low resistivity.

Precautions for use: 1. Keep the surface clean. 2. When using in the soil, the soil resistivity should be less than 15 ohm·m, and it is recommended to use it with a special packing package.

Aluminum alloy sacrificial anode

Product features: light weight, high current efficiency, and low cost.

Scope of application: suitable for ships, marine engineering, seaport facilities, steel pile wharfs, submarine pipelines and circulating water in power plants in seawater media

System, crude oil storage tank, water deposits, etc.

Precautions for use: 1. Keep the surface clean. 2. Avoid collisions with steel structures. 3. It is not recommended to use in the soil.

Sacrificial High Potential Sacrificial Magnesium Anode

Sacrificial Magnesium Anode Specifications:

High Potential HP Magnesium anode are made from high-purity magnesium, they could produce a higher driving voltage than conventional magnesium anodes, so high potential magnesium anodes are suited for structures buried in soils with resistivities in excess of 2,000 ohm/cm.

We adopt special technology, the anodes have superior electrochemical properties, in practical experience, the actual measured driving potential is between -1.8V to -1.85V, thus provide most powerful protection to the targeted structure. The anodes are consumpted uniformly, thereof the anodes have a longer working life.

Our magnesium anode all manufactured and tested according to latest international standards, such as ASTM B843 and ASTM G97,It’s available from both M1C( high Potential)or AZ63B(standard Potential)magnesium anode.

Sacrificial Magnesium Anode Application :

High Potential HP Magnesium anode fight corrosion effectively and economically, and are commonly used in marine environments, soil environment,etc..They protect a variety of steel structures in salt, brackish and fresh water, including: Buried Oil gas Pipelines, Storage tanks, Boats, Ballast tanks, Bulkheads, Pilings, Heat exchangers, etc.

Magnesium anodes corrode much more easily than the materials they are protecting, drawing the corrosion away from equipment.

Lead anode plate /aluminium anode plate for electrowinning / electrorefining / electrolysis

Lead anode plate/aluminium anode plate for copper electrowinning/electrorefining/electrolysis

Lead anode plate/aluminium anode plate for zinc electrowinning/electrorefining/electrolysis

Lead anode plate/aluminium anode plate for manganese electrowinning/ electrorefining/electrolysis

Lead anode plate/aluminium anode plate for nickel electrowinning/electrorefining/electrolysis

Lead anode plate/aluminium anode plate for chromium electrowinning/electrorefining/electrolysis

lead anode plate consists of anode lug, transition row and main board. The transitional row usually consists of tin, silver, cobalt, silicon, germanium and lead. The main board is mixed with calcium, aluminum, silver, tin and lead in a certain proportion. A small amount of rare elements are added, which are respectively prepared by dissolving, mixing, casting, cold pressing, shearing, and stamping.

Lead alloy rolling plate, with uniform crystal structure, is better in anti-corrosion and mechanical performance stability.

The hanger bar core is copper, outside clad a certain thickness Pb and Sn, which has better anti-corrosion to acid mist during electrowinning.

Elegant Group is the most professional company in China to provide our clients with top quality Cathode plates and Anode plates for nonferrous metallurgy. In the past years, Elegant stainless steel/ titanium cathode plates, lead anode plates, aluminium anode plates are widely used in domestic and overseas Copper, steel, gold, nickel, zine, Cobalt and Manganese electrowinning/electrorefining /electrolysis plant for its excellent performance as below:

1. plastic films inside;

2. for small size plate: carton boxes or wooden cases outside

3. for big size plate: pallet or Iron steel frame packing

4. according to your requirements

1, We could produce high quality stainless steel cathode plates/ titanium cathode plates, lead anode plates, aluminium anode plates

2, the shape, the size, the material according to customer demand

3, No MOQ

4, 24 -7 service

Corrosion-resistant metal composite material manufacturer

Caustic environmental protection equipment expert

Titanium/SS clad copper/Al bar/sheet/wire/tube leading provider

Похожие товары

DIN стандартный Профессиональный немецкий шланговый зажим DIN3017

Аккумуляторная дрель Ronix, модель 8612C, двухскоростная, 12 В, 1,5 А, литий-ионная батарея, Аккумуляторная дрель

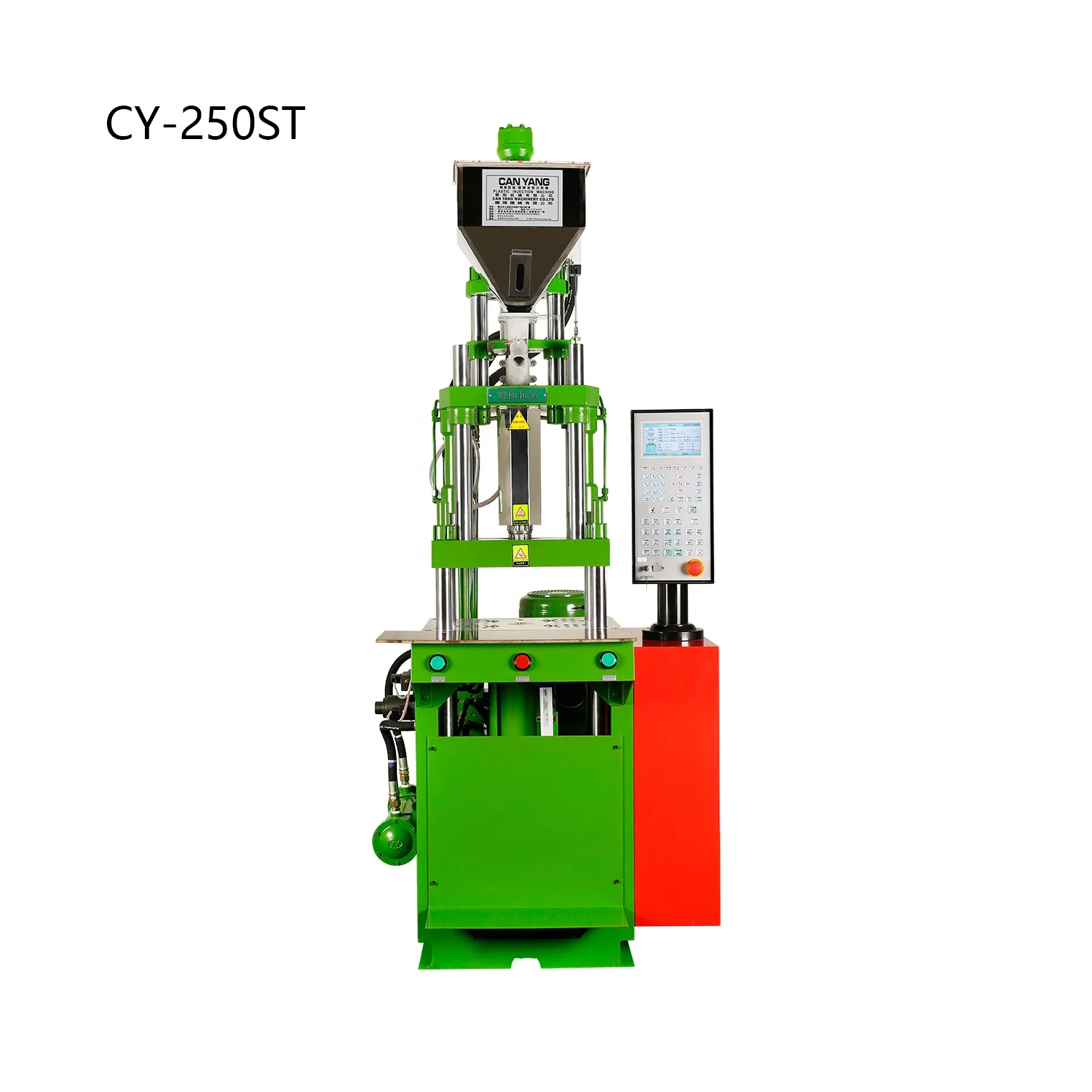

Высокопроизводительное оборудование для литья Пластика под давлением с силиконовым браслетом LSR

Зажим для шланга американского типа 8 мм

Оптовая продажа; Высокое качество; YE2-180M 18.5kw моторный накопитель переменного тока трехфазный асинхронный электродвигатель переменного тока

Китай Baojun американский тип хомуты для шланга из нержавеющей стали продукты

Изготовленный на заказ Высокое качество YE2-180M 18.5kw 660v трехфазный асинхронный электродвигатель переменного тока

Новые поступления

Новинки товаров от производителей по оптовым ценам