Лидер продаж сушилки для замерзания артериальных костей антигидратор из нержавеющей стали распродажа

- Категория: >>>

- Поставщик: ZHEJIANG LEADTOP PHARMACEUTICAL MACHINERY CO. LTD

Сохранить в закладки 1600767177747:

Описание и отзывы

Характеристики

Attention:

1 --- All prices and parameters shown above are automatically generated by the system, if you want to know the exact

information, please click "Contact Supplier" to send mail to us.

2 --- When sending us an enquiry or message, please tell us your Email or WhatsApp/Wechat/Skype .etc, then our sales manager can contact you quickly.

information, please click "Contact Supplier" to send mail to us.

2 --- When sending us an enquiry or message, please tell us your Email or WhatsApp/Wechat/Skype .etc, then our sales manager can contact you quickly.

Products Description

Freeze-dry (brief named Freeze-dry) is a stable process of material dried which will put the material contained with water to freeze to solid first, then make among them of the water sublimate from solid to air condition, removing water to preserve materials.

Vacuum freeze-drying method is a liquid → solid → gaseous process.

Vacuum freeze-drying method is a liquid → solid → gaseous process.

Products at solution stage are frozen through sublimation and desorption, then the solvent reduce to a certain extent, thereby preventing the formation of micro-organisms or chemical reaction between the solute and solvent that products can be preserved for a long time and maintained its nature.

Application

--The bio-products, medicine aspects: such as the anti-virus medicine, anti-toxin medicine, examination products for patients and vaccine conservancy.

--The microbial and algae aspects: such as various bacteria, yeast,enzyme, protozoon, micro-algal etc for the long-term conservancy.

--The drying aspect for food: such as the coffee, tea-leaf, meat, fish, egg, seaweed, fruit, vegetable, dressing, bean curd, instant food etc.

--The top-class nourishment and herb medicine aspect: such as the queen bee syrup, honey, pollen, and chinese herb medicine products etc.

--The microbial and algae aspects: such as various bacteria, yeast,enzyme, protozoon, micro-algal etc for the long-term conservancy.

--The drying aspect for food: such as the coffee, tea-leaf, meat, fish, egg, seaweed, fruit, vegetable, dressing, bean curd, instant food etc.

--The top-class nourishment and herb medicine aspect: such as the queen bee syrup, honey, pollen, and chinese herb medicine products etc.

Features

1. It drys at low temperature in order to make protein degeneration, micro-organisms loss biological activity.

2. The material in the volatile components and nutrients heated degeneration of and aromatic ingredients loss a little because of the low-temperature drying.

3. It is almost impossible for microorganisms and the role to grow so that the material can maintain the original character in the low-temperature drying process.

4.The volume and shape essentially doesn’t change and has a strong water uptake after drying.

5. Because it has little oxygen under the vacuum drying, the vulnerable materials have been protected.

6. It can remove 95-99.5 percent of water, and the retention period lasts longer.

2. The material in the volatile components and nutrients heated degeneration of and aromatic ingredients loss a little because of the low-temperature drying.

3. It is almost impossible for microorganisms and the role to grow so that the material can maintain the original character in the low-temperature drying process.

4.The volume and shape essentially doesn’t change and has a strong water uptake after drying.

5. Because it has little oxygen under the vacuum drying, the vulnerable materials have been protected.

6. It can remove 95-99.5 percent of water, and the retention period lasts longer.

Technical Data

Freeze Drying machine | LTDG-25 | LTDG-50 | LTDG-75 | LTDG-100 | ||||||

Nominal Area(m2) | 25 | 50 | 75 | 100 | ||||||

Capacity | Area of the heat shelf(m2) | 29.9 | 59.9 | 89.9 | 110.1 | |||||

Tray Size(mm) | 780*510*37 | |||||||||

Total Volume Dehydration (Max)(Kg/batch) | 500 | 1000 | 1500 | 2000 | ||||||

Basic Parameter | Heating Shelf | Width | 540mm | |||||||

Length | 1630mm | 3260mm | 4890mm | 6520mm | ||||||

Heating Shelf Range(℃) | Room Temperature-120℃ | |||||||||

Heating Shelf Cooling rate(℃/min) | ≥5℃/min | |||||||||

Heating Shelf heating rate(℃/min) | ≥3℃/min | |||||||||

Condenser Lowest Temperature(℃) | ≤-45℃ | |||||||||

System Lowest Pressure(Pa) | ≤13.3 | |||||||||

Basic Supply | Total Power(kw) | 42 | 75 | 100 | 160 | |||||

Steam Consumption(L/hr) | 220(100) | 450(200) | 670(280) | 900(340) | ||||||

Compressed air consumption:07-1.0Pa.0.9 (L/hr) | 0.45 | |||||||||

Water Consumption: 50℃, 0.10-0.20MPa (kg/batch) | 5 | 10 | 10 | 15 | ||||||

Product Details

Food Grade Material Pipe

Seamless pipe, to achieve the best freezing effect.

Freeze System

Advanced system, with low operating current andlow energy consumption.

Vacuum Pump

Oil-seal vaccum pump,to ensure high efficient operation with equal quality.

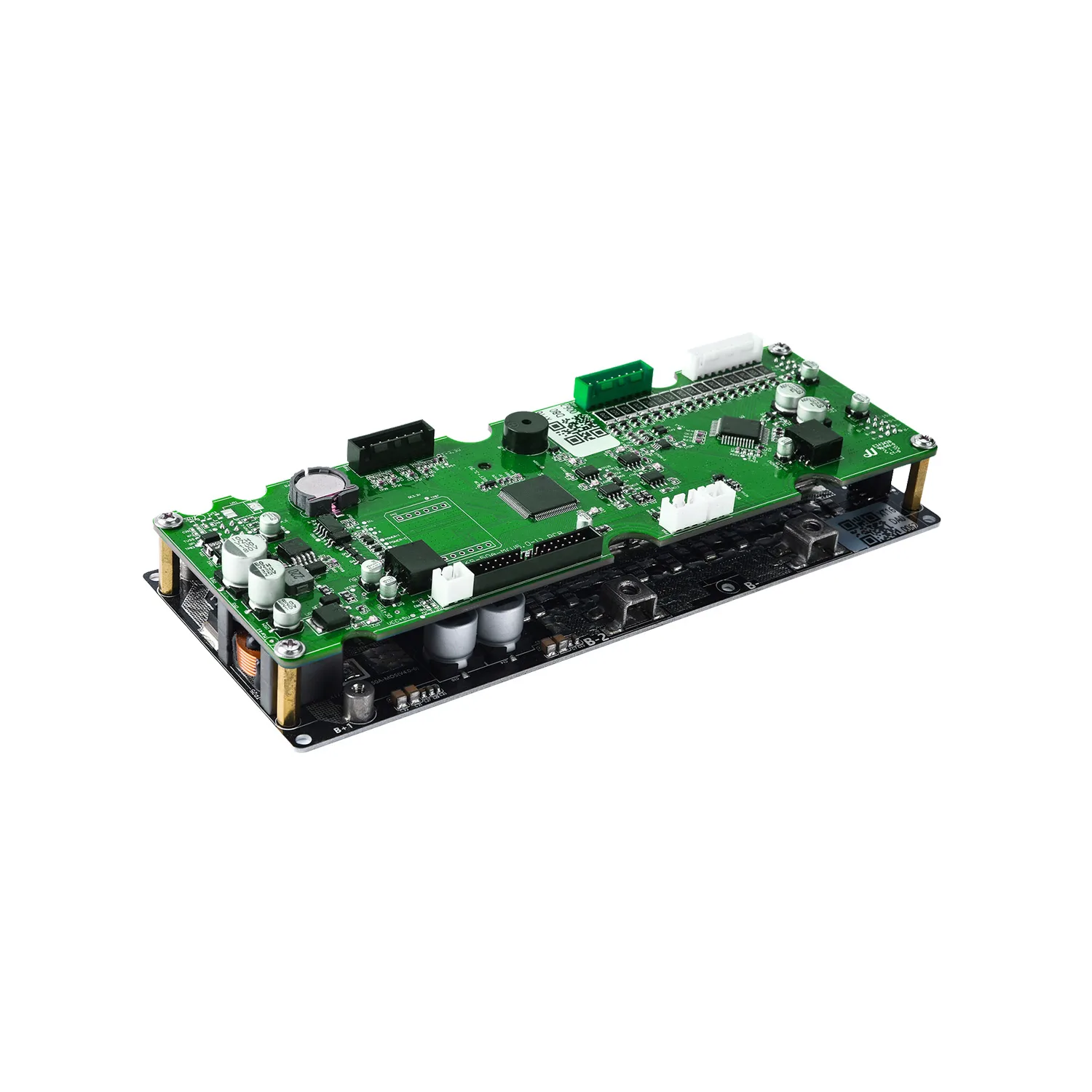

PLC Control

Colour LCD Touch Screen Controller Authorized login with password protection History Parameter Curve.

Company Profile

Our Company

Zhejiang LeadTop Pharmaceutical Machinery Co.,ltd well known as LTPM China. Since year 1996, we are start manufacturing Oral Solid Dosage Pharmaceutical Machinery includes Mixing Machine, Drying Equipment, granulation line, IBC Bin and Bin Washing Machine. As year passed, LTPM China absorb advanced domestic and abroad technology, we export machinery to more than 30 countries all over the world. LTPM China is considered one of the major Pharmaceutical Machinery Supplier and exporter in China mainland. Professional,Enthusiasm, Service and Team Work has been always our value to create for our Staff and customers. As year 2012 we position our value as “A Pharma Machinery Division, For A Better Life”, creating a Win-Win Platform for our clients and staff for a better life is our vision.

Our Certificates

ISO, CE, SGS, BV Certified Company.

Our Machinery Manufacturing Workshop

Imported CNC Machining Centre makes all parts process accurate. Own R&D team with more than 20 years engineering expereince, can customize the equipment and packaging line to your satisfaction.

Our Machinery Manufacturing Workshop

Imported CNC Machining Centre makes all parts process accurate. Own R&D team with more than 20 years engineering expereince, can customize the equipment and packaging line to your satisfaction.

Professional Business Team

Warm, professional business team, careful response to your inquiry, timely response rate of more than 93%, higher than the average level of the industry.

Packing & Shipping

All machine delivery with anti rust spray, film wrapping and Sea shipping affordable wooden box.

FAQ

Q: What price terms you offer?

A: We can offer FOB, FCA, CFR, CIF, EXW and other price terms based on your request.

Q: What payment terms you take?

A: TT, LC, other terms are also workable.

Q: Will you help with installation and stuff training?

A: Yes, we can send our engineers to your place to guide the installation and train your workers if you need, but the buyer should bear our technician's round tickets, accomodation, food and subsidiary USD100/day.

Q: How can I visit your factory?

A: Our factory is located in Ruian city Zhejiang Province. Just let us know your scheduel in advance and we will arrange everything for you!

Any other doubts about our machine, please feel easy to contact with us.

A: We can offer FOB, FCA, CFR, CIF, EXW and other price terms based on your request.

Q: What payment terms you take?

A: TT, LC, other terms are also workable.

Q: Will you help with installation and stuff training?

A: Yes, we can send our engineers to your place to guide the installation and train your workers if you need, but the buyer should bear our technician's round tickets, accomodation, food and subsidiary USD100/day.

Q: How can I visit your factory?

A: Our factory is located in Ruian city Zhejiang Province. Just let us know your scheduel in advance and we will arrange everything for you!

Any other doubts about our machine, please feel easy to contact with us.

Похожие товары

Суперзвуковой бесщеточный двигатель Surpass Hobby ESC Combo 42 серии двигатель 120/150A ESC программная карта для радиоуправляемого автомобиля монстр-ТРАКА ралли 1/10

58,00 $ - 63,00 $

Саржевая стрейчевая джинсовая мужская джинсовая ткань, мягкая хлопковая джинсовая ткань Индиго, джинсовая ткань, текстиль, производители ткани по хорошей цене

2,40 $ - 2,50 $

Фирменная натуральная гидро-маска для лица и подбородка, уменьшающая линию лица, маска для похудения, подтягивающая линию V-образной формы, коллагеновая лицевая маска для лица

0,35 $ - 0,45 $

Телекоммуникационная базовая станция связи литиевая батарея BMS

5 389,04 ₽ - 6 287,22 ₽

Турбокомпрессор RHF55 VF48 VB440057 14411AA700, турбозарядное устройство для Subaru Impreza WRX 2.5L, комплект дизельного двигателя

230,00 $ - 260,00 $

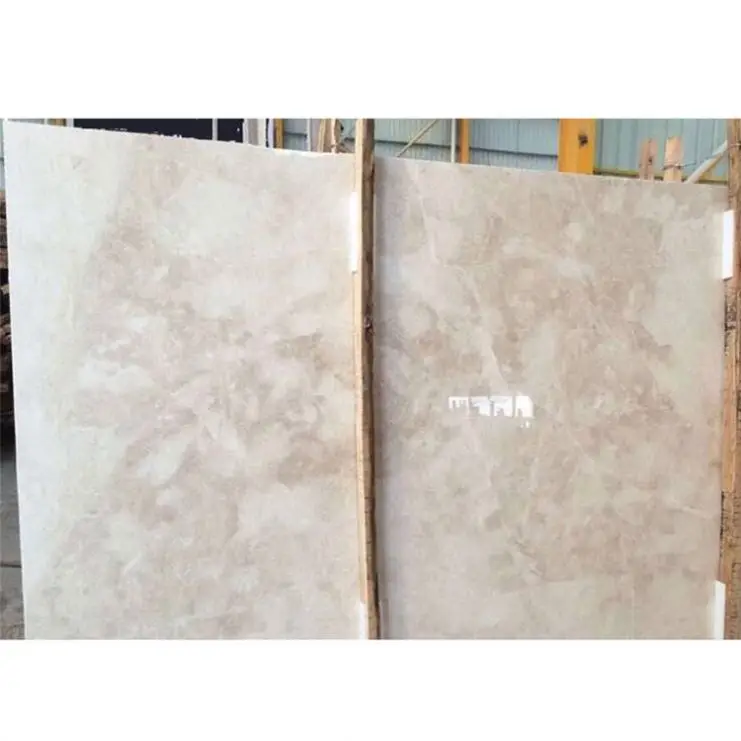

Высокое качество слоновой кости травертин плита Бежевый Травертин Мрамор для

Atomstack P9 M50 50 Вт Мини Портативный стекло гранит камень металлическое engravies резки по дереву, лазерная гравировка машины

479,00 $ - 499,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $

Оригинальная популярная клавиатура для рабочего места Genos2 с 76 клавишами

200 $

Умный цифровой электронный ручной инфракрасный лазерный термометр для ветеринарного и медицинского мониторинга человека

5-10 $

Цифровой инфракрасный лазерный термометр для взрослых

5,90-6,70 $

Командная версия 24-скоростной ультралегкий карбоновый шоссейный велосипед Гоночная рама и комплект колес

Четырехцилиндровый двигатель CA6110/125G5 части клапана 1007011-A013-0000 1007016-A013-0000

0,50 $

55203781 46740344 55181201 55266538 зубчатый шкив коленчатого вала для FIAT 500 BRAVA BRAVO DOBLO PANDA PUNT0

3-3,70 $