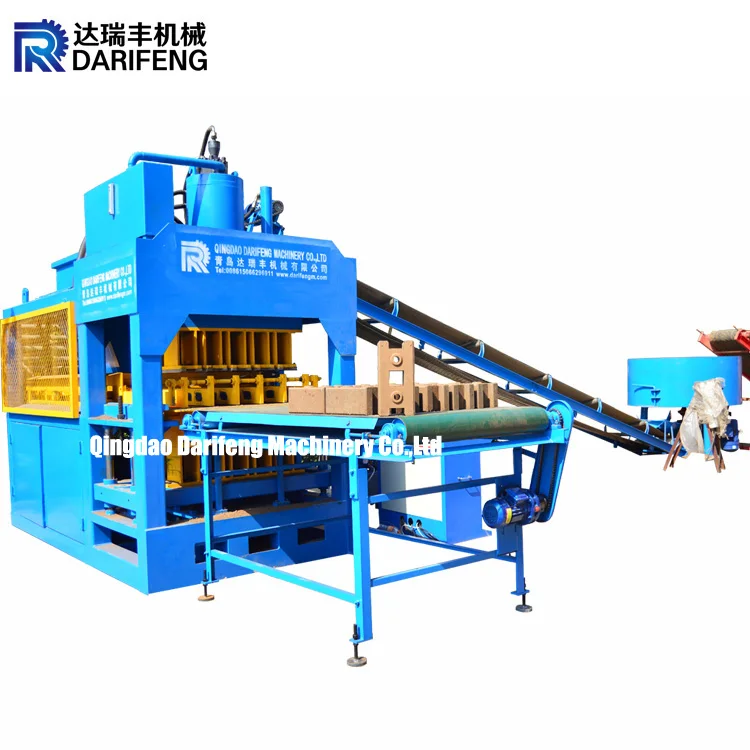

DF10 10S гиперпрессованная машина для кирпича автоматическое изготовление

- Категория: >>>

- Поставщик: Qingdao Darifeng Machinery Co. Ltd.

Сохранить в закладки 1600789600252:

Описание и отзывы

Характеристики

DF10-10S Automatic hydraulic pressure clay soil interlocking brick making machine is our new model high pressure machine model, it added one big hydraulic cylinder based on common DF10-10 brick machine, so DF10-10S total has three cylinder, the pressure can reach to 500tons ( Common DF10-10 pressure can only reach 300tons), which can ensure the brick strength very high.it suitable for making clay bricks, soil bricks, cement bricks and interlocking bricks.

1. DF10-10S can make 10pcs bricks per mould, can make more than 28800pcs in 8hours, so the production capacity is very high, suitable for the customers who want a big capacity.

2. DF10-10S is an automatic hydraulic brick machine which is controlled by PLC, so the machine can be easily operated by only one person.

3. DF10-10S uses a electric motor to drag the CBT-E800 gear pump, Three hydraulic cylinders, the hydraulic pressure can reach 500tons, which can can ensure the brick density very high and brick quality very strong.

4. Mould can be changed according to cusmer's requirements.

5. High productivity.28800 bricks per 8hours.

Technical Specifications | ||

Model | DF10-10S interlocking brick machine | |

Forming cycle | 10s | |

Pcs/mould | 10 pcs | |

Capacity | 28800pcs/8hour | |

Power | 22KW | |

Hydraulic pressure | 500 tons | |

Dimension | 3060x1600x2380mm | |

Weight | 5000kg | |

Brick material | Clay, soil, cement, concrete, fly ash and so on. | |

Darifeng\tMachinery- Profession achieves success

Qingdao Darifeng Machinery Co.,Ltd founded in 1985, is one of the biggest block & brick machine manufacturer in China, our company located in Qingdao City and Linyi City, Shandong Province, covers an area of 126,000 square meters, with 400 staffs, including medium and high-level professionals 100 staffs.

We are a high-tech enterprise, integrating science, industry and export for block & brick machine with our brand more than 30 varieties. Now we have built more than 20000 block production line in China and we also have exported block & brick machine to more than 100 countries, like Philippines, India, Bangladesh, Indonesia, Kazakhstan, Uzbekistan, Nepal, Yemen, Oman, Palestine, Armenia, Sudan, South Africa, Uganda, Mozambique, Tanzania, Ghana, Zimbabwe, Congo, Peru, Colombia, Chile, Paraguay, Bolivia Mexico etc, and have won great fame and popularity.

Our company not only provides customers with various brick and block making machine, but also provides services including process design, workshop design and factory design. In addition, we have a professional engineer team to offer the best after-sales services, such as training workers, imparting technical instruction and fixing problems, we provide all ofour customers 2 year's warranty. We always want to be the best in our industry because we clearly know that only the completely perfect quality and service are the best. Anyway, choosing to cooperate with us is really your wise choice. We are looking forward to cooperating with you.

2) Train the users to command the equipment and guide them for safe production.

3) Explain the routine maintenance of equipment carefully and remove common faults.

4) We are responsible for all the repairs that caused by our quality problems within two year’s warranty. (We will provide one set of spare parts/wear & tear parts free of charge with shipment.)

5) For some countries whose visas are difficult obtained, customers can also send their technicians to our company to receive free guidance and training.

6) Accept suggestions for improvement put forward by customers an earnest way. In accordance with changes of the market, provide the products and services to meet the user’s needs and create value for them.

7) We will make every effort to solve your problems, and your success will add new glory to you.

Похожие товары

25 4 мм 31 75 38 1 Цепной шаг из нержавеющей стали цепная пластина углеродистой конвейерная лента с большой

Вакуумная машина для маринования мяса

1 г-2,3 мм открывающийся оцинкованный лопастной вентилятор с зажимом балансирующие весы/балансирующие весы для вентилятора

PA6 пластиковые Заводские поставки по привлекательной цене, натуральные Чехлы, автомобильные аксессуары, пистолет, военная технология, ключ, стеклянный разъем, цветной гуагуа

Коаксиальный адаптер BNC-SMB RF

Конопли ротанга Плетеный интегрированный большие вертикальные с высокой посадкой Колонка игровой комплекс для кошек из сизаля, игровой комплекс для кошек

Китайский завод, Вибрационный сепаратор для экрана, Вибрационный сепаратор

Новые поступления

Новинки товаров от производителей по оптовым ценам