20 л 45 50

- Категория: Mixing Equipment >>>

- Поставщик: Wuhan Bonnin Technology Ltd.

Сохранить в закладки 1600818309118:

Описание и отзывы

Характеристики

CP001 Small 10L Ink Mixer Instrument, 20L Offset Printing Ink Mixing Machine, 10L Lab Ink Mixer Machine, Flexo Ink Mixing Machine

Main parameters:

Input voltage: 220V

Machine power: 850W

Speed: 0-60 RPM

Exterior size: 600x4000x1000mm

Material bucket size: standard 20L ink bucket

Material bucket capacity: minimum 5KG, maximum 20KG

Net weight: 90-100KG

Packing weight: 120KG

Features:

1. Simple and convenient operation.

2. Low-speed, intermittent pail side stirring;

Unique agitator design, ink can be in the process of stirring, shearing, within five minutes will be evenly mixed ink;The stirring ink does not heat up.

3, stirring speed can be fast.

4. Simply replace the agitator (standard 20L ink drum) and lock the ink tank with one key.

5. Agitator: L-shaped agitator, integral forming, without a screw hole, easy to clean.

6. Transmission mode: direct transmission to reduce power loss.

7, mixing time can be set, the body design is compact and easy to move.

HK-320 Flexography Printing Proofer Machine Automatic Flexo Ink Printing Proofer

1.Applicable objects: monochrome proofing (such as color matching, testing, etc.)

2.Input power: 220V, 50/60Hz

3.Power: 400 w

4.Ink: dropper ink

5.Proofing material thickness: 0.01-2mm (bendable material)

6.Proofing material size: 190x240mm

7.Printing area: 100x130mm

8.Plate area: 150X 150mm

9.Plate thickness: DUPONT: 1.14mm. Tessa (double-sided adhesive tape) :0.38mm

10.Plate roller and screen roller pressure: adjustable by 2mm soil, with scale to show the pressure 11.Plate roller and press pressure: can be adjusted by 2mm soil, there is scale to show the pressure 12.Printing speed adjustable: 0-80 m/min

13.Ceramic roller specifications :100x210mm

14.Number of ceramic roller lines: standard 600LPI (70-1200 lines can be customized).Suitable for: flexographic water - based, UV ink, lithography, letterpress or UV ink

16.Suitable proofing materials: paper, plastic film, non-woven cloth, napkin, gold and silver card paper,etc

17.Dimensions (length x width x height) : 450x800x240mm

Automatic Flexo Gravure Ink Offset Printing Proofer Machine

The automatic color spot offset printing proofer can print different color strips or the same ink color stripe with different ink layer thickness at the same time. It can also print new and old ink on the same printing material for comparison. Provide efficient color contrast.

Applicable to: printing offset printing ink spot color proofing, ink color matching; testing ink hue, wet and dry, gloss, Lab value and other printing suitability.

Characteristics:

1. Spot color proofing

The multi-segment color developing instrument can print color bars of different colors or the same ink color bars of different ink layer thicknesses at the same time. It can also print new and old ink on the same printing material for comparison, providing efficient color contrast.

2. Four-color ink detection

It can detect the hue, gloss and color density of the ink; start with the control of the quality of the ink raw materials, so as to achieve the purpose of controlling the quality of the printed products.

3. Approval of pre-print spot colors for customers

Simple color bars can be made for customers to approve or archive before printing.

4. Detect the degree of discoloration of dry and wet ink

The color bar of the spot color ink exhibited by the color development machine exhibits the hue of the spot color after drying naturally. (For example, the phenomenon that purple and dark blue will turn red after drying can be eliminated before printing.

5. It can be used in conjunction with the ink meter to predict the amount of spot color ink used, greatly reducing residual ink consumption and warehouse accumulation.

6. Data management

Cooperate with the spectrodensitometer for color detection and can measure the data report (Lab value) of the color bar.

7. Cooperate with related instruments to predict the characteristics of ink wear resistance, fading, transfer, light resistance and heat resistance.

2. Speed: Printing speed range: high speed: 20 R / min, medium speed: 15 R / min, low speed: 10 R / min

3.Color Bar size: Effective size of color bar: 45x225mm

4. Paper specification: Imprint 0 ~ 2.50 mm thick paper and 1 mm thick plastic film

5. Steal roller speed, cleaning: 100-800 r/m, proofing: 100-1000 r/m

6. Proofing speed: High: 1000r/m, Medium: 800r/m, Low: 650 r/m

7. Automatic uniform ink, stable operation, precision processing,time adjustable.

Technical Parameters:

| Proofing speed | 0-130 m / min, touch screen adjustment |

| Roller size | dia.67X229mm |

1. Ink color stripe effective area optional: 40X220mm (4 strips) 60X220mm (3 strips) 100X220mm (2 strips), 290X250mm

2. Proofing time, printing pressure and speed can be adjusted. Printing speed low, medium and high

Pressure: 0-2MM

3. Spectrometer to measure color, detect, dry and wet, gloss, lab value

4. Pressure:0-2MM

5.N/G Weight:: 280MM*690MM*380MM

6.Input Voltage: 220V 50Hz

7.Power: 400W

Advantages:

Even ink mode:

1. The ink leveling speed can be switched between automatic and manual, suitable for different operating habits and special situations;

2. Set the soft start mode for intermediate positioning and non-concatenating in series, reduce the unevenness of color development and ink flying phenomenon, and improve the precision of color development;

3. Four-stage ink leveling mode time setting (each segment can be set to 0-200 seconds), can be set to any ink leveling mode: positioning in series, intermittent close, fixed close and automatic speed change

More accurate and user-friendly; 4. Ink leveling pressure (automatic): can be automatically adjusted according to the rubber roller wear condition or the error of the old and new rubber rollers.

5. Color development pressure (automatic): automatically adjusted according to the color development material thickness (-1 ~ +1 mm), more accurate and convenient.

6. Cleaning: The metal roller does not move in the cleaning mode, which is safe and convenient.

7. Rubber roller: Standard and UV dual-purpose roller is standard.

Похожие товары

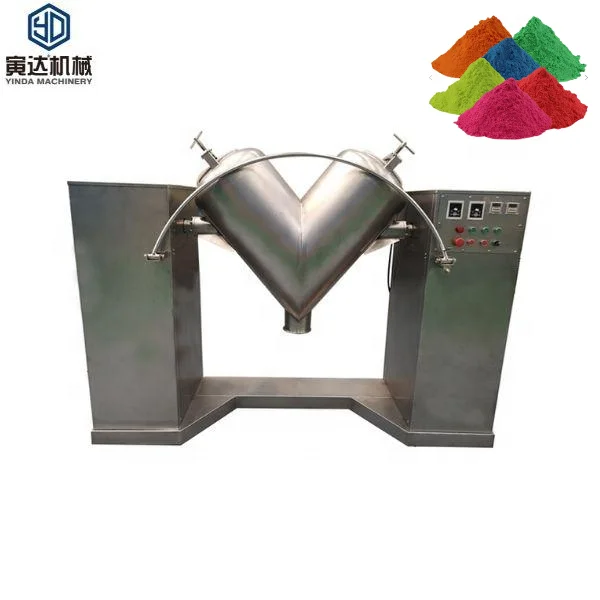

Горячая Распродажа V-образная смешивающая машина фармацевтическая химическая Косметическая пудра

Бесплатная доставка байонетный замок статический смеситель/одноразовые силиконовые смеситель

Недорогой лабораторный аппарат цифровой трубчатый ролик с ЖК-дисплеем для измерения

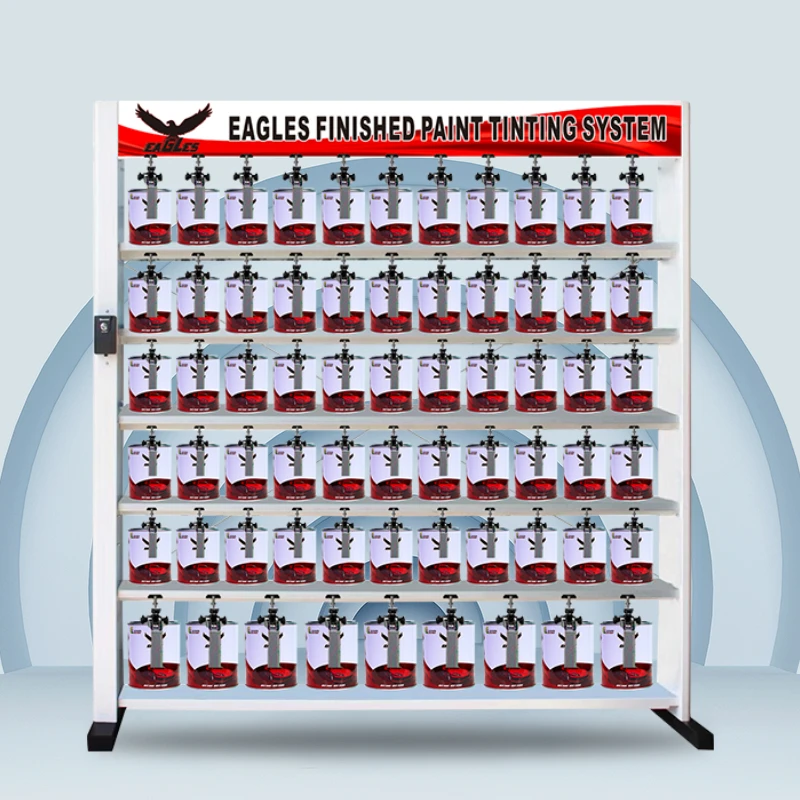

1K 2K Автомобильная Машина Для Смешивания Краски с крышками для смешивания краски

Химические смешивающие резервуары CHINZ с мешалками сосуды коммерческое оборудование для производства йогурта производственный

Высококачественные вязкие жидкости мешалка MachMix-серии смесители для боковых входных

Гомогенизатор серии SS304/316L смеситель с высоким сдвигом диспергирующий

Новые поступления

Новинки товаров от производителей по оптовым ценам