Автоматическая машина для производства бетонных блоков из полистирола

- Категория: >>>

- Поставщик: Henan Fantianliang Machinery& Equipment Co. Ltd.

Сохранить в закладки 1600906216074:

Описание и отзывы

Характеристики

Automatic polystyrene concrete block making machine eps foam moulding machine

Polystyrene concrete block/ EPS foam concrete is a composite material consisting of Portland cement and its varieties, silica aggregate (silica sand or fly ash from thermal power station), a porous filler (foamed polystyrene granules)and modifying agents (setting accelerators, plasticizers, etc.)When we control the ratio of the components in the mixture we can get different brands of polystyrene on the indices of the average density in the dry state from D150 to D600. As a result we get both constructional and insulation material.

Manufacturing technique of polystyrene concrete

- Foaming of polystyrene granules;

- Drying (maturing)of polystyrene granules;

- Batching of raw components;

- Preparation of polystyrene concrete;

- Molding of polystyrene concrete mass;

- Hardening of polystyrene concrete mass;

- Cutting the polystyrene concrete mass into blocks with specified sizes;

- Storage of polystyrene concrete blocks.

- Foaming of polystyrene granules.

Water utilisation | ~7.5 tonnes/shift |

Cement utilisation | ~16,5 tonnes/shift |

Polystyrene utilisation | ~500 kg/shift |

Required production facility area | 500-1000 m2 |

The ceiling height at the mixing area | not less than 6 m |

The ceiling height at the production area | not less than 3 m |

Ambient temperature | not be less than +15 |

Required personnel | 6 workers, 1 production manager/foreman |

Brief introduction of the production process:

1. Preparation of raw material

it includes Expanding polystyrene, Adding water into the mixer, Loading the mixer with raw materials

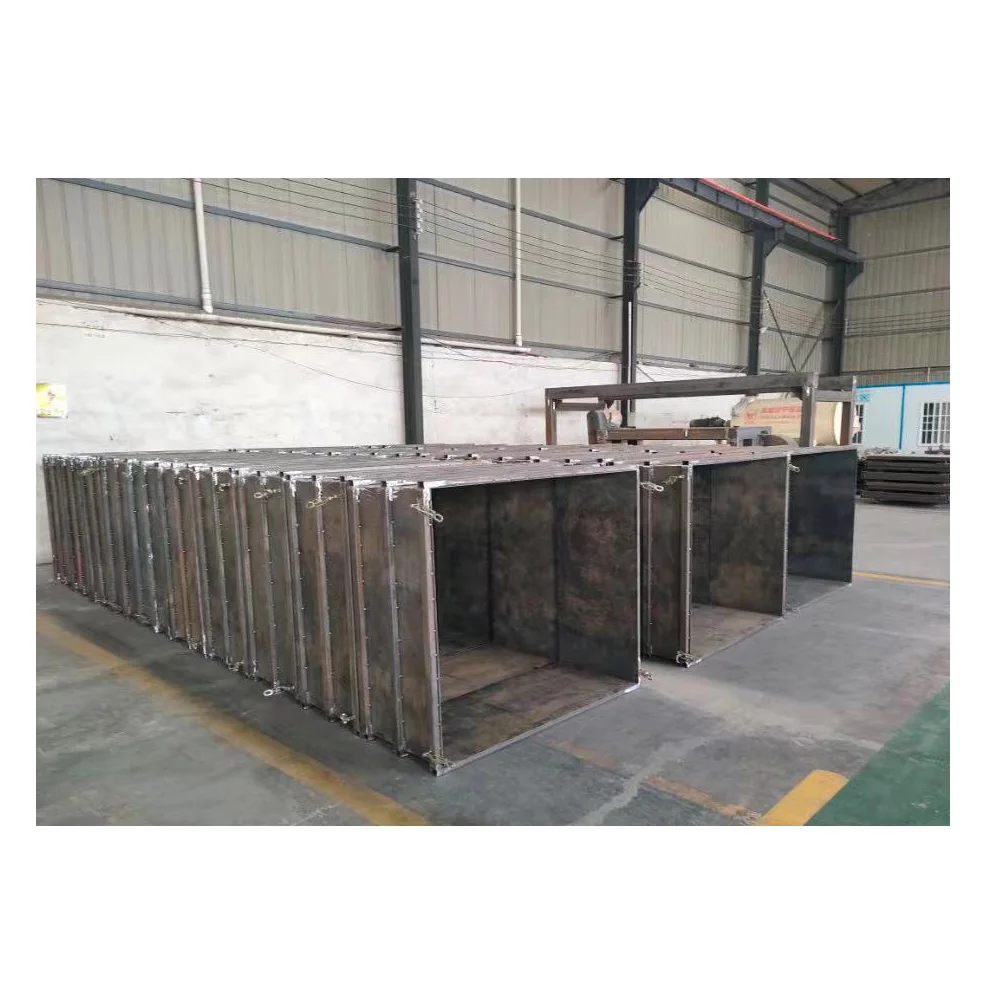

2. Moulding a block

The mould is made up of the base and removable, interchangeable walls. Before casting, the mould is lubricated and transported to the mixing section where the casting is done.

3. Block ageing

After casting, the mould is transported along the railway to the ageing section, where the block is kept until it gets strength enough for removing the walls. The strength enough for removing the walls can be gained within 4 to 7 hours and depends on polystyrene density, cement activity, temperature, etc.

4. Dismantling moulds and cutting

5. Stacking blocks onto pallets, packing, and storing

Final Product:

clink here for our AAC block production line

Похожие товары

Новый переключатель OEM датчик давления передатчик с

Высококачественный компрессор воздуха

HONGSBELT HS-501EL изогнутые Модульный пластиковый ленточный конвейер для наклонный конвейер

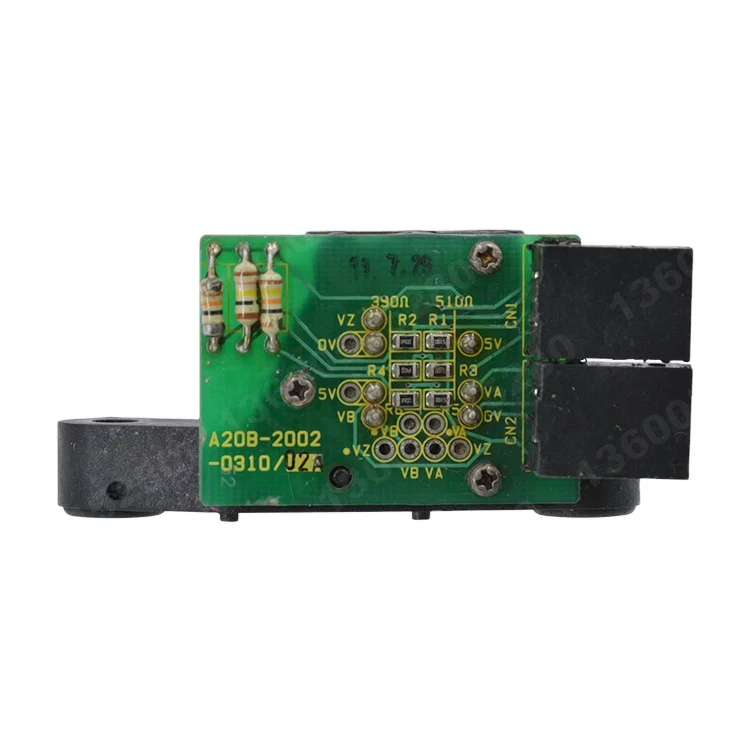

100% тестирование оригинальные fanuc шпинделя датчик A20B-2002-0310

Универсальное автомобильное радио 7 дюймов сенсорный экран беспроводной Carplay /Android Авто Стерео Dvd плеер Ips планшет

Вертикальный горизонтальный держатель ID карты бейдж катушка с любой печатью логотипа

Хит продаж, багги для дюн 1100cc 4x4 EPS go karts (TKG1100-1)

Новые поступления

Новинки товаров от производителей по оптовым ценам