Naipu 28/24 ГПП высокохромовый осадочный загуститель шламовый насос

- Категория: >>>

- Поставщик: Shijiazhuang Naipu Pump Co. Ltd.

Сохранить в закладки 1600952310604:

Описание и отзывы

Характеристики

Centrifugal slurry pump introduction -

NPAH(R)-series are suitable for severe slurry conditions with coarse particles and high competency:

2.1 Two types of material for wet parts (volute liners, front and back liners, impellers):

l high-chrome alloy

l highly wear-resistant rubber

2.2 Structure of shaft seals:

l Packing gland seals

l Pressure-reducing metal/ rubber gland seals

l Mechanical seals

NPAH slurry pump performance parameters and pictures

Type | Max. Power Kw | Flow m³/hr | Head/m | Speed/rpm | Efficiency % | NPSH m | Nos of Vane | Diameter mm |

1.5X1 B-NPAH | 15 | 12.6-28.8 | 6-68 | 1200-3800 | 40 | 2-4 | 5 | 152 |

2X1.5 B-NPAH | 15 | 32.4-72 | 6-58 | 1200-3200 | 45 | 3.5-8 | 5 | 184 |

3X2 C-NPAH | 30 | 39.6-86.4 | 12-64 | 1300-2700 | 55 | 4-6 | 5 | 214 |

4X3 C-NPAH | 30 | 86.4-198 | 9-52 | 1000-2200 | 71 | 4-6 | 5 | 245 |

6X4 D-NPAH | 60 | 162-360 | 12-56 | 800-1550 | 65 | 5-8 | 5 | 365 |

8X6 E-NPAH | 300 | 360-828 | 10-61 | 500-1140 | 72 | 2-9 | 5 | 510 |

10X8 F-NPAH | 560 | 612-1368 | 11-61 | 400-850 | 71 | 4-10 | 5 | 686 |

12X10 ST-NPAH | 560 | 936-1980 | 7-68 | 300-800 | 82 | 6 | 5 | 762 |

14X12 ST-NPAH | 560 | 1260-2772 | 13-63 | 300-600 | 77 | 3-10 | 5 | 965 |

16X14 TU-NPAH | 1200 | 1368-3060 | 11-63 | 250-550 | 79 | 4-10 | 5 | 1067 |

20X18 TU-NPAH | 1200 | 2520-5400 | 13-57 | 200-400 | 85 | 4-10 | 5 | 1370 |

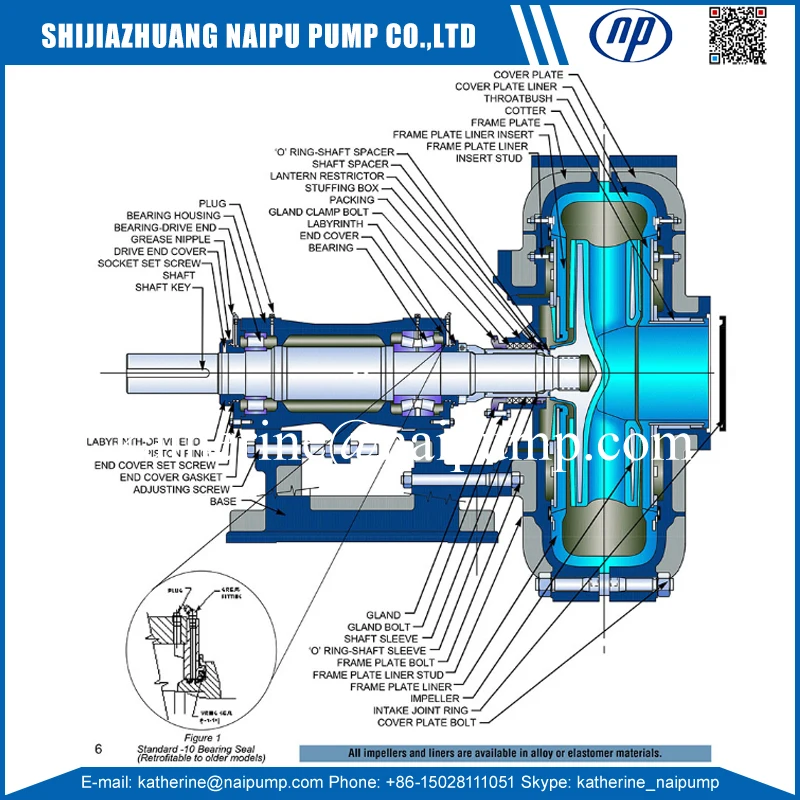

NPAH slurry pump construction drawing

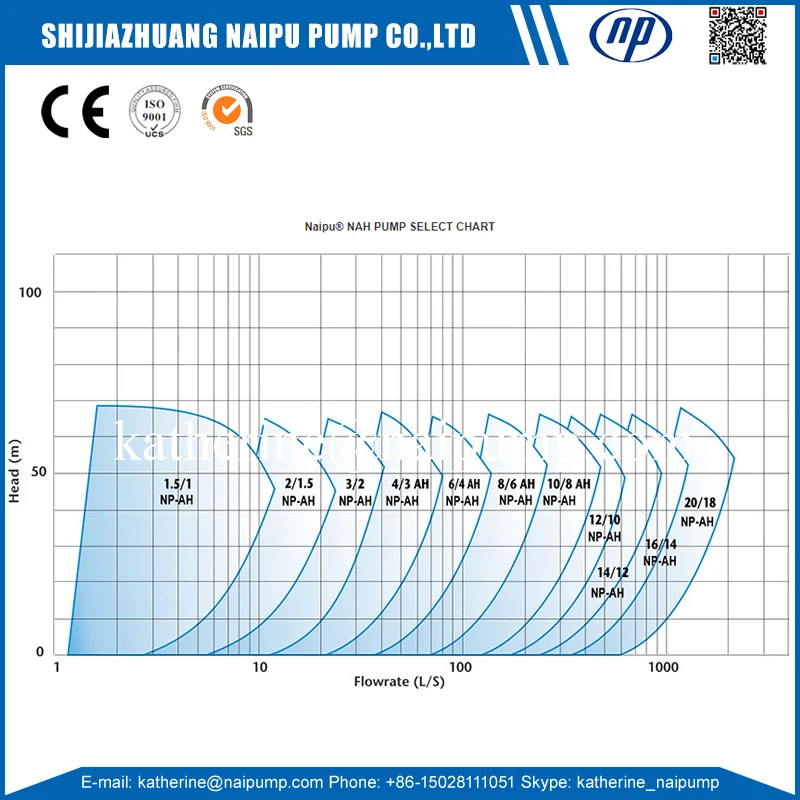

NPAH mining slurry pump selection chart

CE, SGS, ISO9001 Certification

Possible faults and removal

Type NPAH slurry pump has a compact construction. If it is correctly installed and operated, the pump will have a long life.

| Faults | Reason | Removal |

| Pump fails to discharge any liquid. | Incorrect direction of pump rota- tion and impeller worn. Suction pipe blocked | Check direction of rotation and replace a new impeller |

| Power consumption on shaft is excessive | Rotating component is rubbing on a stationary part. Bearing worn. Drive belt tension too tight Flow rate too large Pump speed and ratio too high. Misalignment or unparallel of ddrive shaft and pump shaft. | Removal the rub Replace the bearing Adjust belt Modify the pump duty and speed. Adjust drive and pump shaft |

| Bearing is over hearing | Lubricants too much or less. Containing impurities in the lubricant Bearing worn. | Lubricating as requirements. Replace clean lubricant. Replace new bearing. |

| Bearing has short life. | Misalignment or unparallel of drive and pump motor. Shaft bent. Impeller unbalanced due to wear Foreign object entered into the bearing or insufficient lubrication Incorrect procedure followed in fitting bearings. | Adjusting drive and pump shaft. Replacing shaft. Remove rubbing and replace new impeller Clean the bearing. Replace or refit the bearings. |

| Pump vibrates or is noisy. | Bearings worn. Impeller unbalanced. Air entered into suction pipe or blocked. Flow rate is none—uniform and pump not primed. | Replaced by new bearings. Replaced by new impeller. Discharge air and remove block. Improve on the pump feeding. |

Похожие товары

Высококачественный Электрический водяной насос 380 В 50 кВт IEC1 с двигателем для морской ирригационной сельскохозяйственной обработки OEM настраиваемый

Центробежный водяной насос KYSB с разделенным корпусом

Полностью нержавеющая сталь 304/316/316L/2205/2507 корпус центробежный насос трех типов фланец

Лабораторный безмасляный вакуумный насос 24 В для отбора проб газа

PP пластиковая химическая кислота доказательство пневматический двойной мембранный насос с воздушным управлением

MK06/10 15/20 1/4 1/2 дюймов небольшой химический насос сильная кислота Щелочная КОРРОЗИОННАЯ ЖИДКОСТЬ передача промышленный мембранный воздушный насос

Резиновая диафрагма 04-1020-51, используется для пневматического диафрагменного насоса Wilden, Неопреновая диафрагма для насоса Wilden 1,5 дюйма

Новые поступления

Новинки товаров от производителей по оптовым ценам