8/6 6/4 4/3 керамические накладки крыльчатки шламовые насосы и запасные части

- Категория: >>>

- Поставщик: Shijiazhuang Naipu Pump Co. Ltd.

Сохранить в закладки 1601018552186:

Описание и отзывы

Характеристики

8/6 6/4 4/3 Ceramic Lining Impeller Slurry Pumps

We also can produce ceramic slurry pump and spare parts of silicon nitride bonded silicon carbide (Si3N4-SiC). Ceramic slurry pump and Pump Parts has many excellent characteristics, such as abrasion resistance and corrosion resistance. These parts are continuously used for coal power generation, non-ferrous foundry, mining and other industries.

The corrosion and wear resistance of ceramic slurry pump parts far exceed those made of high chromium alloys. The abrasive resistance of ceramic (Si3N4-SiC) material is 3.13 times that of Cr15Mo3. However, the weight of Si3N4-SiC material is only 1/3 of that of alloy parts.

According to a number of key technical requirements such as ceramic material properties, molding processes, heat treatment processes, etc., metal-lined ceramic integral forming structures such as pump body, impellers and liners have been developed.

In addition, we can also produce ceramic coated stainless steel shaft sleeve with the material code J04, J05, J21, J24, J25, J26, J27, J31.

High-quality 8/6 6/4 4/3 Ceramic Lining Impeller Slurry Pumps, designed to meet all your pumping needs. These centrifugal pumps are perfect for cross-border e-commerce platforms, ensuring efficient and reliable performance.

Featuring a ceramic lining impeller, these pumps offer exceptional durability and resistance to wear and tear. The ceramic material enhances the pump's lifespan, making it ideal for heavy-duty applications. With various sizes available, including 8/6, 6/4, and 4/3, you can choose the perfect pump to suit your specific requirements.

Our slurry pumps are designed to handle abrasive and corrosive fluids, making them suitable for a wide range of industries. The robust construction ensures smooth operation and minimal maintenance, saving you time and money. These pumps are also highly efficient, delivering maximum performance while reducing energy consumption.

Invest in our 8/6 6/4 4/3 Ceramic Lining Impeller Slurry Pumps and experience the difference in pumping efficiency and reliability.

Material Data and advantage

Ceramic are made of Si3N4-SiC(Silicon Nitride Bonded Silicon Carbide)is a kind of inorganic nonmetallic materials.

Its wear-resisting performance is 3.13 times of Cr15Mo3 with Mohs Hardness 8.9, only after Diamond and Cubic Boron Nitride. Compare with similar products, our ceramic density is about 5% higher than others, and double flexural strength higher at normal temperature.

The corrosion and abrasion resistance of ceramic slurry pump parts are higher than the ones made by high chrome alloy. The abrasion resistance of Si3N4-SiC material is 3.13 times as wearable as Cr15Mo3. However the weight of Si3N4-SiC material is only 1/3 of high chrome alloy parts.

Ceramic SlurryPump Parts

ShiJiaZhuang NaiPu Pump Co.,Ltd , is direct factory of slurry pump, sand gravel pump , dredging pump , Water pump and spare parts .

NaiPu Pump is devoted to pump solution industry for more than 30 years!

NaiPu Slurry Pumps can be 100% totally interchange with famous brand, and can help customer save 30% cost.

The Pumps are widely used in in metallurgy, mining, Nonmetallic Mining, Coal, Energy

resources, Sand mining, Dredging, Environmental protection, Petrochemical engineering, Flue gas desulfurization and other industrial departments.

The Pumps are exported to USA, Canada, Germany, Russia , Australia, South Asia, North America, South Africa, and etc , up to more than sixty countries.

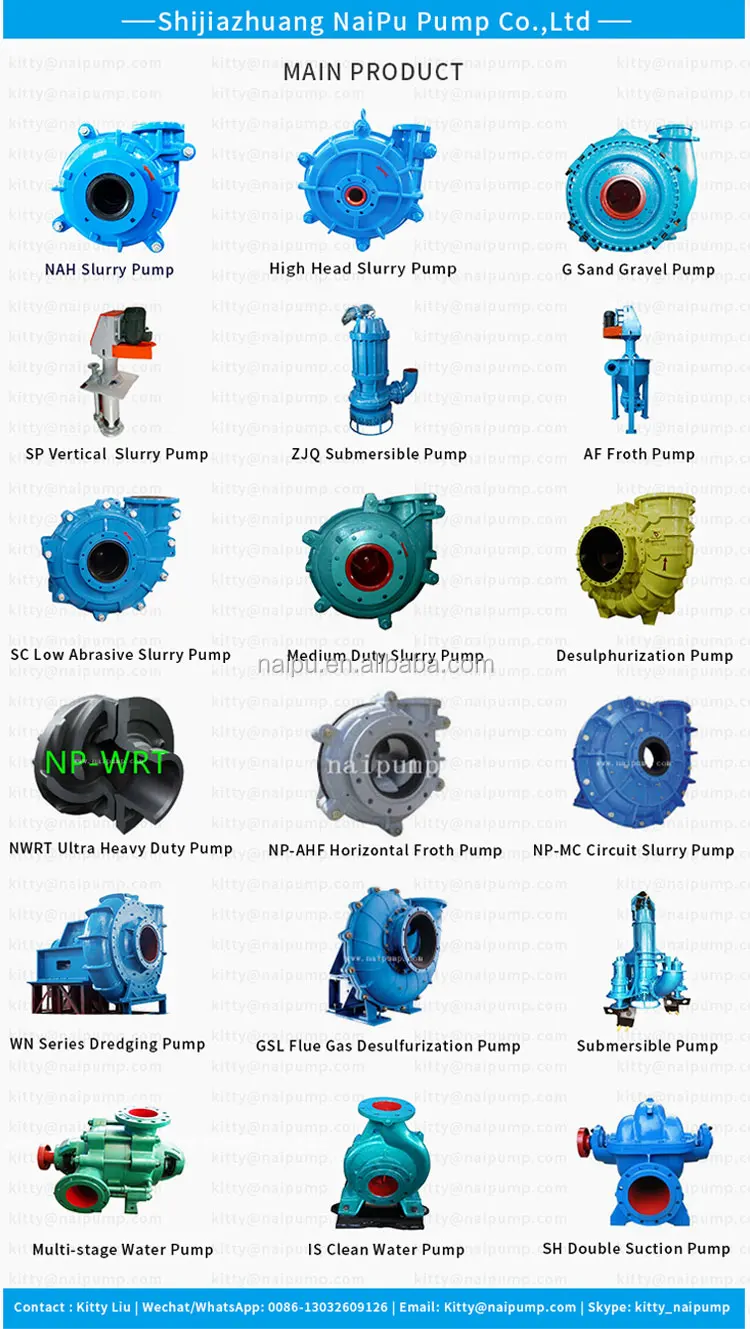

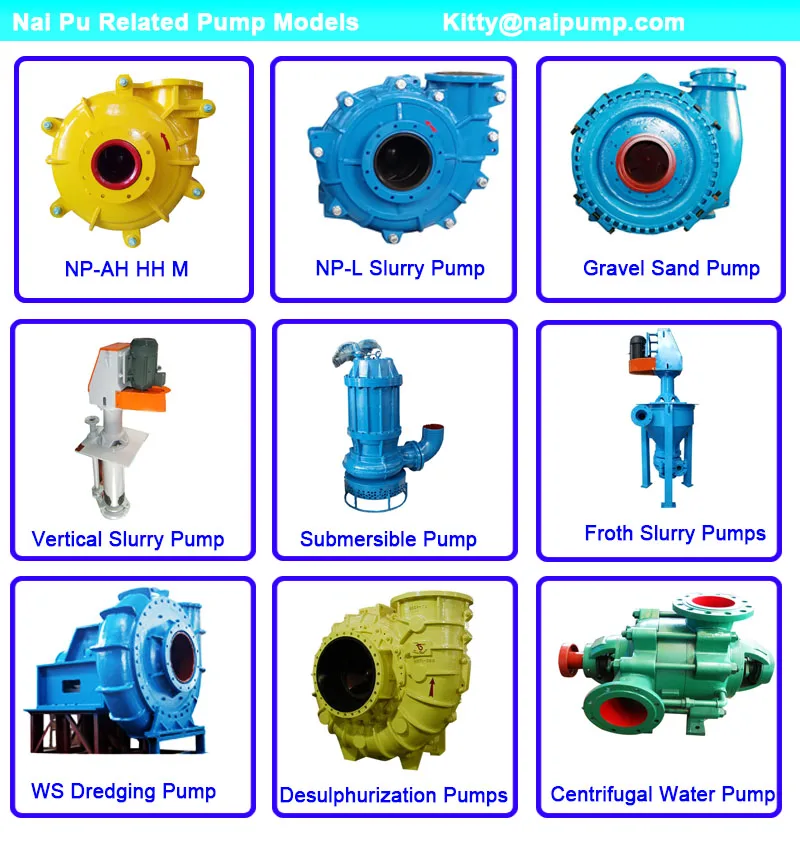

NaiPu Main products

1. NAH , HH L Horizontal Slurry Pump

2. SP Vertical sump pump

3. ZJQ Submersible slurry pump

4. G Horizontal sand gravel pump

5. ZJQ Submersible sand pump

6. WS Dredging pump

7. AF Vertical Froth Pump

8 .AHF Horizontal Froth Pump

9. TL(R) Desulphurization Pump

10.Clean Water Pump

11. OEM Casting machinery wear parts

Slurry Pump Model

Main Slurry Pump Parts : Impeller , Volute Liner , Casing , ThroatBush, Frame Plate Liner Insert , Cover Plate , Frame Plate, Pump Liner Expeller , Expeller Ring ,Stuffing Box , Expeller , Pump Shaft , shaft sleeve, Shaft Spacer, Bearing Assembly , Base, Stuffing Box, Gland Assembly, Bearing Housing , Lantern Ring , pump discharge pipe , flange , and so on.

OEM Service

We can produce Wear parts according to drawing or sample as customer's requirement.

The parts are widely used in Main Applications: Heavy Mining | Mineral Processing | Sand and Gravel |Coal Prep | Cyclone Feeds | Aggregate Processing | Fine Primary Mill Grinding | Chemical Slurry Service | Tailings | Secondary Grinding | Industrial Processing | Pulp And Paper | Food Processing | Cracking Operations | Ash Handling | Pipeline Transport | High Velocity Hydraulic Transport |Food Processing | Explosive Sludge In Metal Smelting | River And Pond Dredging | Heavy Refuse Removal | Larger Particle Or Low NPSHA Applications | Continuous (Snore) Sump Pump Operation | Abrasive Slurries | High Density Slurries | Large Particle Slurries | Sump Drainage | Wash down | Floor Drainage | Mixing | Iron Ore | Cooper | Diamond | Alumina | Coal | Gold | Kaolin | Phosphorite | Steel | Palm | Suger | Chemical | Power | FGD | Frac Sand Blending | Construction | City Sewage | etc.

1. Direct Factory

we are the directly Pump factory with more than 30 years pump production experience.

NaiPu has its Casting workshop, Machining workshop, Assembly Workshop. There are only few real factory , most only have assembly workshop or trader. We can control the quality better.

welcome to visit our factory anytime.

2. Excellent Product Quality.

All our workes have more 20 years experience and skilled in casting , machning and assembly industry,

We have advanced and perfect testing equipment, and strict quality inspection is required at every production link.

3.Technical Surport .

We have a group of high quality engineers with rich experience who can solve everything during the whole process. like select the right pump model , required Power , and other technicial trouble during using

4. Reasonable Price

Naipu Pump can save about 30% cost for the buyer

5.Perfect after -sales .

We will be responsible for the whole life period, No matter any trouble during using , just email me , we will help you to solve it.

6. Rich OEM Service Experience

Not only for pump and spare parts , also for other others mining wear parts. we have done many special spare parts for customer. Like Crusher spare parts , Cyclone parts , ball mill Liner . Material can be High chrome alloy A05,A49,A61,A07, Stainless steel , Ductile Iron, Alloy 20, Hastalloy C and so on

7. Quick Reply

Your inquiry related to our products or prices will be replied within 8 hours. if urgent can call me or add wechat/ whatsapp:86-13032609126 .

ShiJiaZhuang NaiPu Pump Co.,Ltd

Contact person : kitty Liu

Email: kitty at naipump.com

Mobile /whatapp: +86-13032609126

Skype: kitty_naipump

Welcome to contact us for more details about 8/6 6/4 4/3 Ceramic Lining Impeller Slurry Pumps and Spare Parts

Disclaimer: Warman, Goulds and Metso and others are the brand names of the respected owners. Any use of competitor names, trademarks, model numbers or part numbers by NaiPu Pump are for reference purpose only and do not imply that any part or pump listed is the product of Weir Warman Pumps, ITT Goulds Pumps and Metso Pumps.

Похожие товары

Масляный насос промышленного класса 5 кВт 50 Гц/60 Гц

ШЛАМОВЫЙ НАСОС ОДНОСТУПЕНЧАТЫЙ В КОМПЛЕКТЕ С ЭЛЕКТРОДВИГАТЕЛЕМ.СПОС

1 5/1 HH 1-Дюймовые маломощные шламовые насосы с Высокой Головкой

Сверхмощный Центробежный 300m 3/h шламовый насос 75 кВт

4 дюйма эластомер вкладыш центробежный резиновый шламовый насос

Naipu 10 дюймов высокое абразивный центробежный насос медная горно-bomba de poro

Выставочный шламовый насос Naipu 8/6F-HA для добычи металла

Новые поступления

Новинки товаров от производителей по оптовым ценам