1 5/1 HH 1 Дюймовые маломощные шламовые насосы с Высокой Головкой

- Категория: >>>

- Поставщик: Shijiazhuang Naipu Pump Co. Ltd.

Сохранить в закладки 62533330027:

Описание и отзывы

Характеристики

NP- HH Slurry pump applications

NP-HH slurry pumps are suitable for pumping slurry with high-hardness, strong-corrosion and high-concentration liquids that contain suspended solid particles, such as finished ores, refuse ores, ashes, cinders, cements, mud, mineral stones and etc. in the industries of metallurgy, mining, coal, power, building material and etc. The temperature of the pumped solid-liquid mixture should be ≤80oC, and the weight concentration should be ≤60. These pumps can also be applied multi-staged in series.

High Head slurry pump advantages

The positions of the NP-HH slurry pump outlet can be positioned at an interval of 45°according to different requirements, so eight different angles can be applied by rotation in installation.

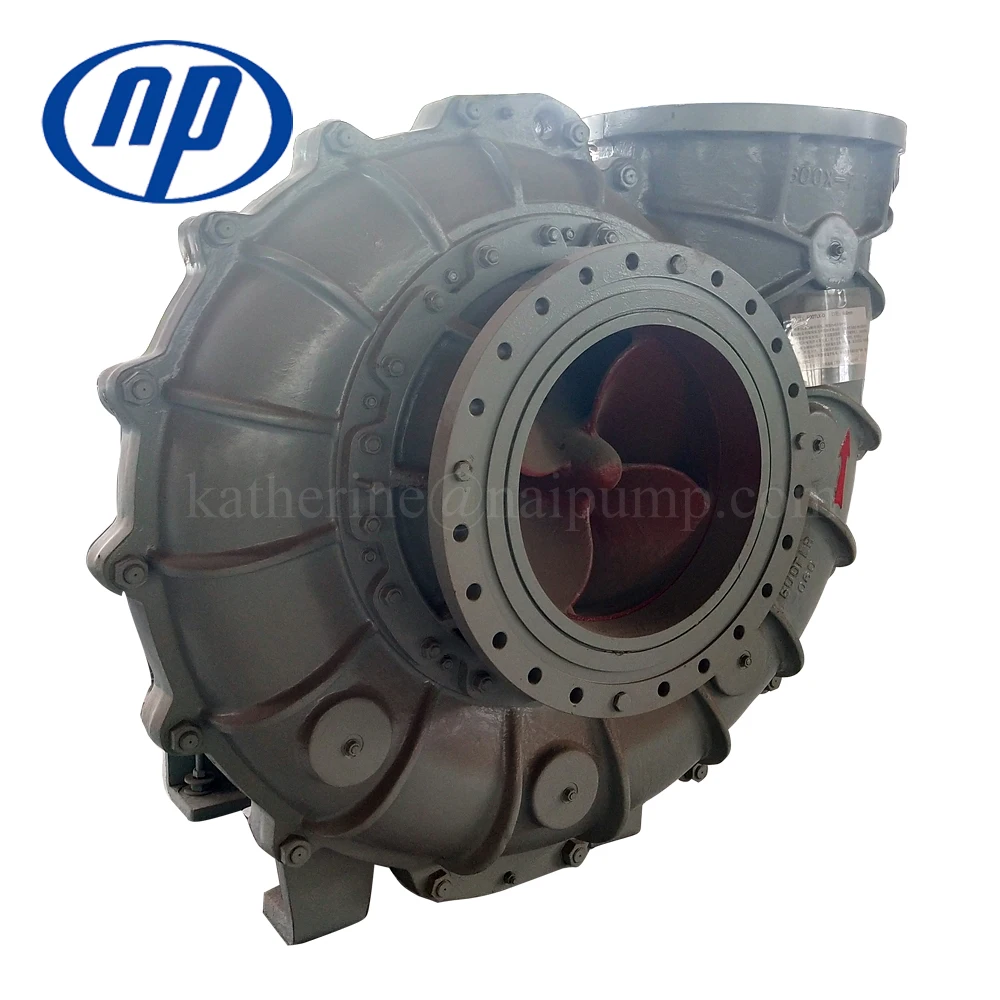

The NP-HH type horizontal slurry pumps have pump bodies (volute liners, front and back liners) that consist of replaceable wear-resistant metal liners or wear-resistant rubber liners, and impellers can also apply wear-resistant metal material or wear-resistant rubber material.

The NP-HH type mining slurry pump only apply wear-resistant metal material as their pump bodies and impellers.

Slurry pump construction drawing

NP-HH Metal Slurry Pump Main part number at the drawing

| 032: Frame Plate 060: Intake Joint 132: Discharge Joint 083: Throatbush 110: Volute Liner | 147: Impeller 122: Stuffing Box Seal 013: Cover Plate 124: Volute Liner Seal 041: Frame Plate Liner Insert |

NP-HH series High Head Slurry Pump Materials of construction

| LINERS | IMPELLERS | CASING | BASE | EXPELLER | EXPELLER RING | SHAFT SLEEVE | SEALS | |

| Standard | Chrome Alloy | Chrome Alloy | SG Iron | SG Iron | Chrome Alloy or SG Iron | Chrome Alloy or SG Iron | SG Iron | Rubber |

HH slurry pump selection chart

( Note: Approximate performance for clear water,to be used for primary selection only.)

HH Mining Slurry Pump performance parameters

| Type | Allowable (Kw) | Clear Water Performance | Impeller | ||||||

| Capacity m³/hr | Head m | Speed rpm | Max Efficiency | NPSH m | Nos of Vane | Diameter mm | |||

| 1.5/1 C-HH | 30 | 16.2-34.2 | 25-92 | 1400-2200 | 20 | 2-5.5 | 5 | 330 | |

| 3/2 D-HH | 60 | 68.4-136.8 | 25-87 | 850-1400 | 47 | 3-7.5 | 5 | 457 | |

| 4/3 E-HH | 120 | 126-252 | 12-97 | 600-1400 | 50 | 2-5 | 5 | 508 | |

| 6/4 F-HH | 560 | 324-720 | 30-118 | 600-1000 | 64 | 3-8 | 5 | 711 | |

| 8/6 S-HH | 560 | 468-1008 | 20-94 | 500-1000 | 65 | 4-12 | 5 | 711 | |

Naipu pump produce many kinds of centrifugal slurry pump for mining, sand and other solids slurry transporting.

Packaging details: 1. Outside package: standard export wooden cases. 2. Inner package: Stretch film.

Shijiazhuang Naipu Pump Co., Ltd is a professional manufacturing enterprise of slurry pumps. We have about 30 years experiences and export to worldwide countries. Our technical team consists of talents specialized in hydraulic machinery, casting, heat treatment, engineering, material science and machining. We proudly manufacture quality pumps whose parts are 100% reverse interchangeable with major brands. This means no more inventory hassles when you decide to use another pump supplier.

High Head Slurry Pump Quality Control

| Stages of manufacture | Quality cotrol activities | Specification |

| Raw material arrival | Sampling, material chemical analysis | NPB121.1-29-1997 |

| Casting and composition | Material material chemical analysis of pump parts | NPB121.1-29-1997 |

| Casting quality inspection | NPB302-1998 | |

| Key component machining | Dimension precision inspection | NPB2105-87 |

| Impeller balancing | NPB061-2000 | |

| General assembly | Procedure operaion | NPB2103-96 |

| Hydraulic static test | NPB064-1998 | |

Performance test of pump unit | Capacity and head | NPB157-1997 |

| Vibration and noise | JB/T8097-95 | |

| Bearing temperature | JB/T5295-91 | |

| Final inspection | Packaging of pump unit | NPB0157-1997 |

| Documents | NPB0157-1997 | |

| Spare parts and accessories | NPB0157-1997 |

1. Our pumps quality has reached domestic and internaional advanced level in this field.

2. We are responsible for our products quality, if there are some quality problems after you received, we will be prmptly returned or replacement the kits.

CE, SGS, ISO9001 Certification

Katherine Hou

+86 15028111051

Похожие товары

4 дюйма эластомер вкладыш центробежный резиновый шламовый насос

Naipu 10 дюймов высокое абразивный центробежный насос медная горно-bomba de poro

Выставочный шламовый насос Naipu 8/6F-HA для добычи металла

Naipu 8 / 6 G-HH Газоочиститель высокого давления 6-дюймовый шламовый насос

ЗАПАСНЫЕ ЧАСТИ К НАСОСАМ ДЛЯ ГОРНОДОБЫВАЮЩЕЙ ПРОМЫШЛЕННОСТИ8/6EE

Оптовая продажа высококачественный пневматический насос высокого давления для смазки с смазочным пистолетом экспорта

Мощный десульфурационный насос Naipu 600TL FGD для электростанции

Новые поступления

Новинки товаров от производителей по оптовым ценам