Щитки от грязи, брызговики, переднее и заднее колесо для Chery Jetour x95 x90, автомобильные аксессуары

3,50 $ - 5,75 $

Сохранить в закладки 1601018769098:

Model | 5 | 25 | 50 | 100 | 150 | 200-2000 | |||||

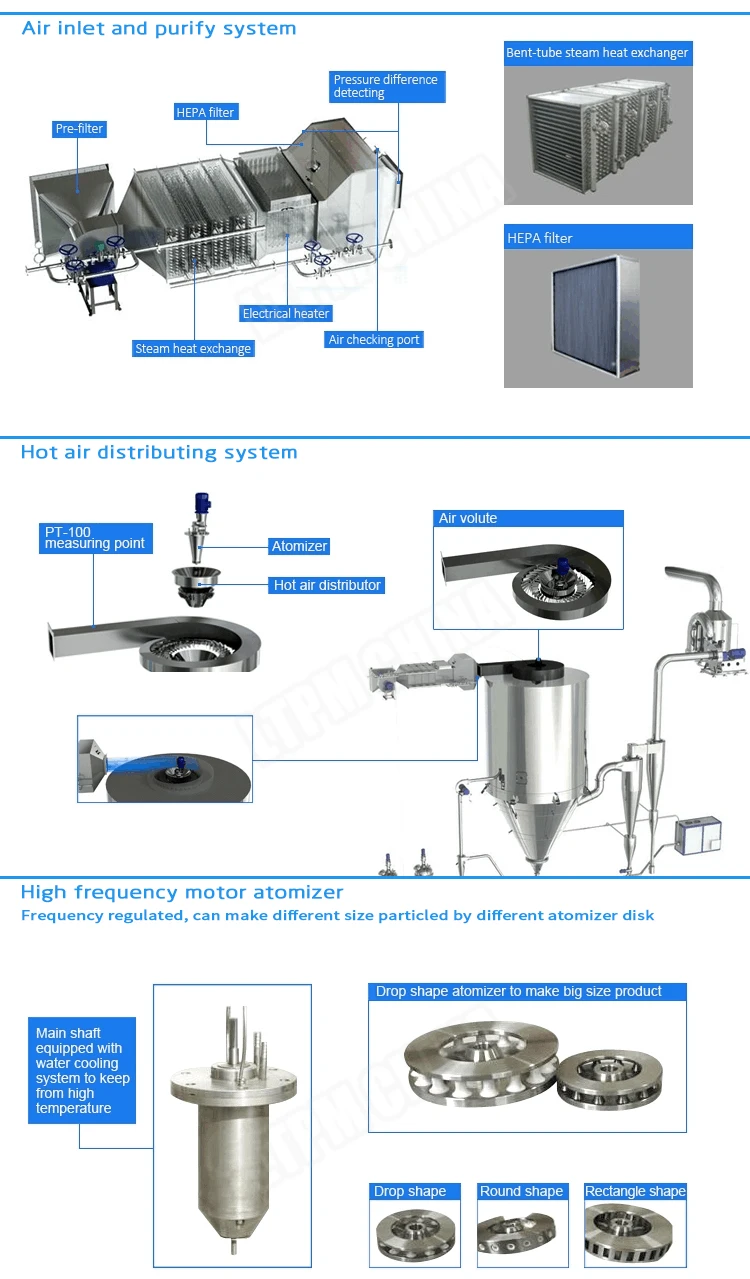

Inlet temperature | 140-350°C(automatic control) | ||||||||||

Outlet temperature | 80-90°C | ||||||||||

Max. evaporation(kg/h) | 5 | 25 | 50 | 100 | 150 | 200-2000 | |||||

Centrifugal spraying nozzle transmission mode | compressed air transmission | mechanical transmission | |||||||||

Rotation speed (r.p.m) | 25000 | 22000 | 21500 | 18000 | 18000 | 15000 | |||||

Spray disc diameter | 50mm | 100mm | 120mm | 140mm | 150mm | 180-340mm | |||||

thermal source | electricity | electricity | electricity + steam, fuel, oil, fuelgas | solved by user | |||||||

Max. electric heating power (kw) | 8 | 31.5 | 60 | 81 | 99 | ||||||

Overall dimension | 1.8*0.93*2.2 | 3*2.7*4.26 | 3.7*3.2*5.1 | 4.6*4.2*6 | 5.5*4.5*7 | optional | |||||

Powder recollection (%) | 95 | 95 | 95 | 95 | 95 | 95 | |||||

Новинки товаров от производителей по оптовым ценам