Роликовый сепаратор мусора/машина для скрининга каменных грязевых примесей

- Категория: >>>

- Поставщик: Henan Huayuan Machinery Equipment Co. Ltd.

Сохранить в закладки 1601055489332:

Описание и отзывы

Характеристики

Detailed introduction:

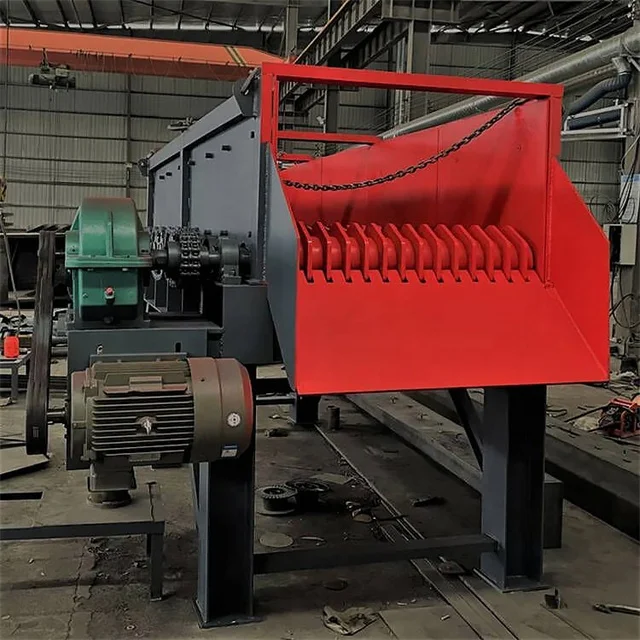

In the sand production line, in order to reduce the working pressure of the crusher, the bulk material in the raw ore needs to be screened out in advance, some materials are more sticky, pebbles, river pebbles are often wrapped in mud, in order to quickly remove the mud wrapped in the stone, you need a roller screen equipment. The screen surface is designed for materials that are not easy to separate. In the process of operation, the material is constantly thrown up, which is easier to disperse the material and improve the screening rate.

The working principle of the mud separator:

The rotating shaft with irregular shape device is driven by the motor to flip the motion, the screen surface is composed of many linear arrangement of rotary bearings, there is an equal arrangement of screen discs on the roller, the roller rotates through the gear driven wheel chain drive, the direction of rotation is consistent with the direction of the flow of raw materials, and there is a gap between the shaft and the shaft. The irregular wear-resistant device embedded in the shaft holds the large particle size material forward, because the screen shaft is designed according to different running directions, so the speed is faster when the material runs in the higher running direction; The speed of the material is slower when it runs in a lower direction. The two materials running at different speeds begin to do axial operation when they converge at a certain place on the screen surface, so that the material is evenly distributed on the screen surface to improve the efficiency of screening, and the small particles fall into the bottom of the separator and are sent out by the belt conveyor.

The working principle of the mud separator:

The rotating shaft with irregular shape device is driven by the motor to flip the motion, the screen surface is composed of many linear arrangement of rotary bearings, there is an equal arrangement of screen discs on the roller, the roller rotates through the gear driven wheel chain drive, the direction of rotation is consistent with the direction of the flow of raw materials, and there is a gap between the shaft and the shaft. The irregular wear-resistant device embedded in the shaft holds the large particle size material forward, because the screen shaft is designed according to different running directions, so the speed is faster when the material runs in the higher running direction; The speed of the material is slower when it runs in a lower direction. The two materials running at different speeds begin to do axial operation when they converge at a certain place on the screen surface, so that the material is evenly distributed on the screen surface to improve the efficiency of screening, and the small particles fall into the bottom of the separator and are sent out by the belt conveyor.

Advantages of mud and rock separator:

1. Separately driven, each screen shaft is driven separately by a motor reducer, that is, each group of screen shafts has a set of driving devices.

2. Flexible without jamming, each screen axis rotates in the same direction and has overload capacity. The rotating parts rotate flexibly and there is no jamming phenomenon.

3. Used for boiler coal-burning crushing, suitable for boiler coal-burning system and coal mine coal preparation system, pre-screening coal particle size.

4. The screen shaft is multi-angled, and the screen shaft is reasonably arranged at multiple angles. The angle between the screen shaft and the horizontal at the entrance section of the equipment is 15 degrees, and the angle between the screen shaft and the horizontal at the exit section is 5 degrees, so that the coal material enters the equipment and the material layer is uniform distributed.

2. Flexible without jamming, each screen axis rotates in the same direction and has overload capacity. The rotating parts rotate flexibly and there is no jamming phenomenon.

3. Used for boiler coal-burning crushing, suitable for boiler coal-burning system and coal mine coal preparation system, pre-screening coal particle size.

4. The screen shaft is multi-angled, and the screen shaft is reasonably arranged at multiple angles. The angle between the screen shaft and the horizontal at the entrance section of the equipment is 15 degrees, and the angle between the screen shaft and the horizontal at the exit section is 5 degrees, so that the coal material enters the equipment and the material layer is uniform distributed.

Похожие товары

Машина для дробления соли оборудование производства морской промышленное измельчение

1 080 070,74 ₽ - 1 322 535,60 ₽

Портативная дробилка для тяжелой молотковой коробки добычи полезных ископаемых

165 316,95 ₽

Горная щековая дробилка первичная Известняковая песчаниковая базальтовая высокопроизводительная каменная обслуживание двигателя Max.3t/h

319 502,56 ₽ - 330 413,48 ₽

Высококачественная высокотехнологичная Двухвалковая дробилка для угля мощностью 500 тонн/час мобильная

Скидка 14 ~ 36 т/ч машина для камнедробилки б/у установка продажи

1 377 641,25 ₽ - 1 653 169,50 ₽

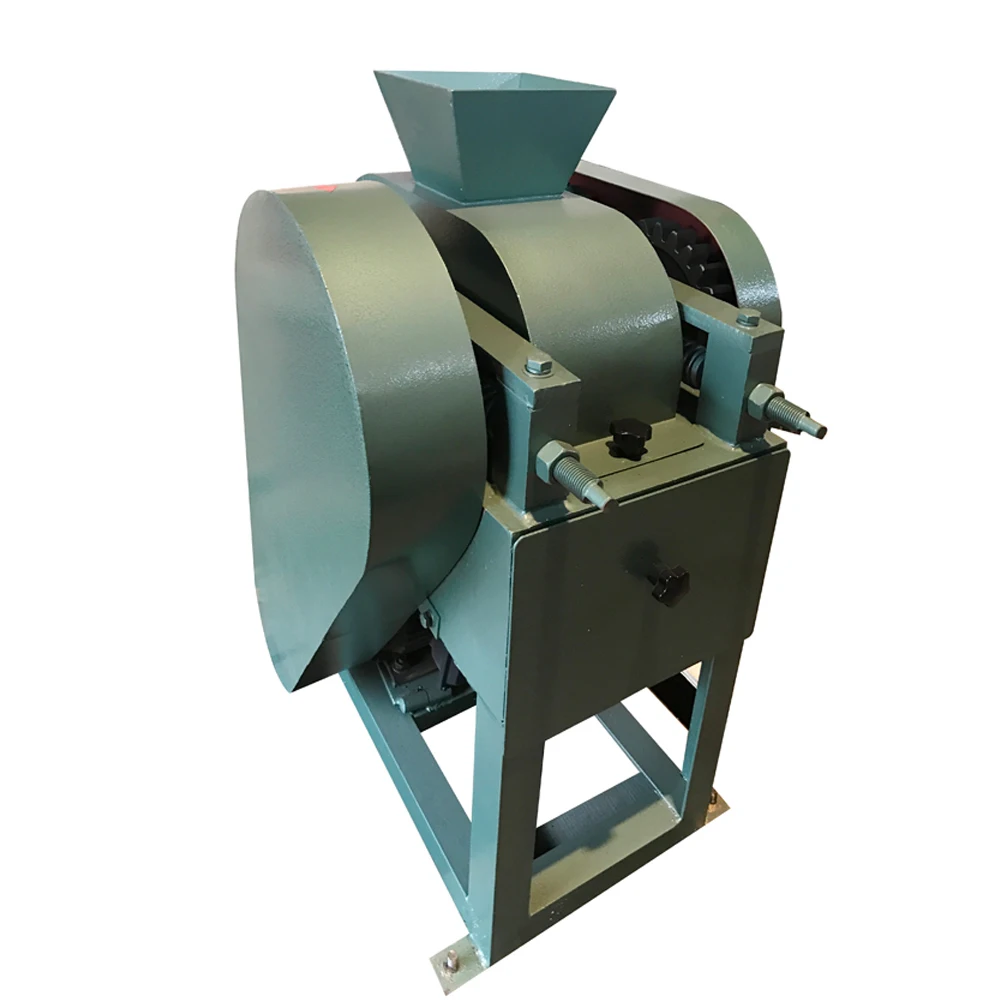

Небольшой Размер 200*75 лабораторная двойная дробилка для измельчения руды мини каменная мелкого дробления камня

88 169,04 ₽

Pe250 * 400 Подержанные каменные детали машины портативный дизельный двигатель роликовый небольшой щековая дробилка

378 024,76 ₽ - 385 739,55 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $