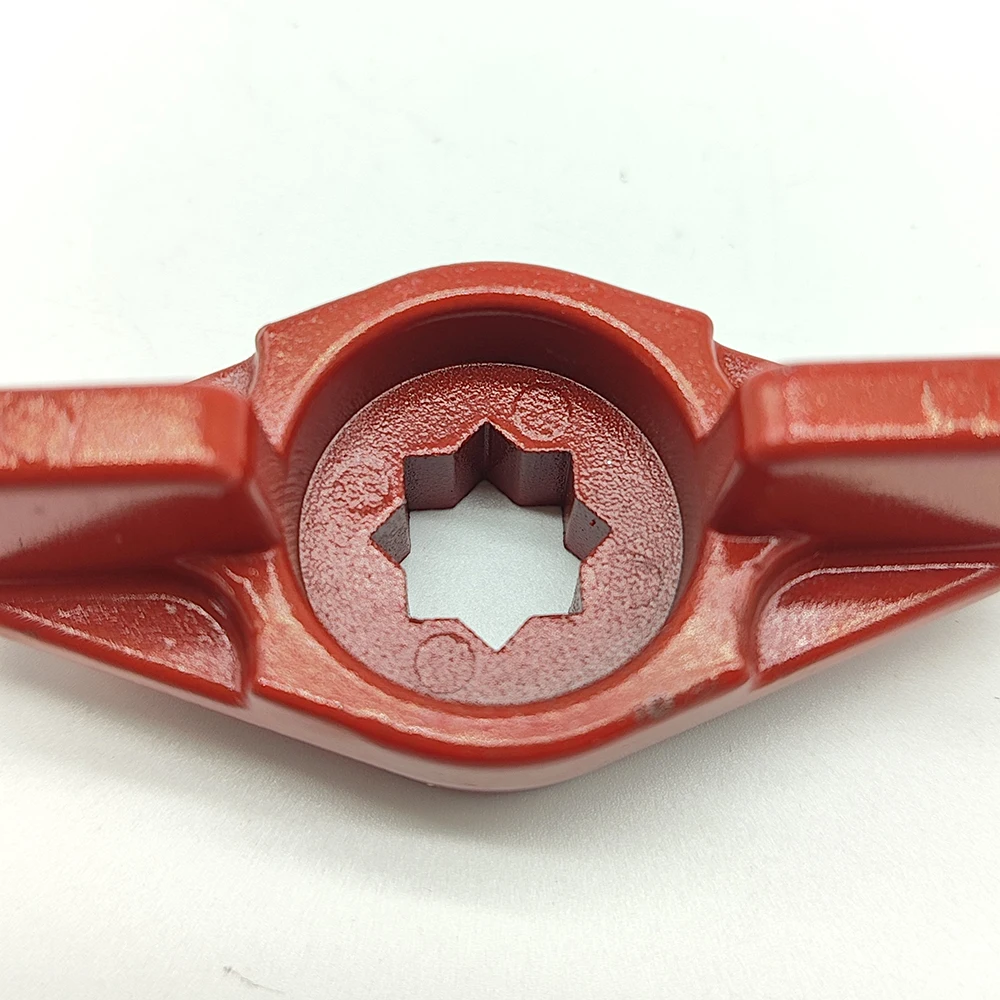

Фабрика Ningbo Jisheng сертификация ISO9000 изготовитель по индивидуальному заказу Автомобильная застежка от солнца крепежная пряжка металлическая литая деталь

- Категория: >>>

- Поставщик: Ningbo Jisheng Foundry Industry Co. Ltd.

Сохранить в закладки 1601062161013:

Описание и отзывы

Характеристики

Aluminum alloy die casting manufacturers gravity casting aluminum parts.

PRODUCT DESCRIPTION

| Casting Service | Gravity Casting,High Pressure Die Casting,Low Pressure Casting,Cold Extrusion (aluminum, copper),Stainless Steel (Precision Casting), Silica Sol Casting |

| Material | Aluminum,Stainless Steel (upon your requirements.) |

| Certificate | IATF 16949:2016 |

| Standard | ASTM, DIN,JIS, EN, ISO, GB standards |

| Precision Machining | CNC turning, milling, drilling, grinding, cutting, reaming and threading. |

| Surface Treatment | Surface Treatment,Polishing, Painting,Brushing,PVD,Sandblasting, Anodizing,Power coating,Plating,Elecctroplating,Chrome Plating |

| Product | All kinds of casting and machined parts:Auto parts;Valves; Glass clamps so on. |

| Packing | Export Standard Carton |

| Inspection | A.Have full inspection and routing inspection during mass production----In-process B.quality control(IPQC) C:Checking the goods after they are finished----Final quality control(FQC) D:Checking the goods after they are finished----Outgoing quality control(QC) E.100% inspection and delivery before shipment. |

| Delivery Time | Normally 30-45 Days,but some of them depend on the quantites request. |

Ningbo Jisheng Casting Industry Co., Ltd. is located in Haishu District, Ningbo City, Zhejiang Province, close to Ningbo International Airport. The company was founded in 2017, is a zinc alloy, aluminum alloy, copper casting, scientific research, development, production, sales as one of the professional manufacturing and export production enterprises. After years of dedicated management, the enterprise is recognized as the foundry industry Jiao Jiao, stepped into the forefront of the industry. Since entering the market for more than 20 years, the products cover the fields of auto parts, construction machinery parts, hydraulic pump valve body, transportation facilities parts, pneumatic tool parts, ship parts, etc., the customer base covers all over the country, most of the products are exported to the United States, Germany, Italy Asia, Switzerland, Spain, Hong Kong, Macao, Taiwan and other markets.

The company has more than 150 employees, 45 above junior college, 7 engineers. With an excellent aluminum alloy, zinc alloy, casting product R & D team and modern production, testing, testing equipment. The company has 160 ~ 800 tons of automatic force die casting machine 9 sets, gravity casting machine, Wanfeng low pressure casting machine and other casting equipment, at the same time equipped with vertical four axis machining center 10 sets, CNC CNC drilling machine 10 sets, CNC CNC lathe 20 sets, CNC milling machine, horizontal lathe and other high-precision processing equipment. The testing equipment includes Italian spectral material analyzer, CMM, Sanfeng altimeter, image measuring instrument, coating measuring instrument, universal tensile testing machine, aluminum liquid hydrogen measuring instrument, Rockwell, Brinell hardness tester, Large industrial X-ray flaw detector and other special testing equipment.

For different customers have different products,as a manufacture,we have more than thousands of models of aluminium parts products. Our advantage that has 28 years history in this business field.

Our main products include food mechnical,aviation mechnical accessories, bridge spot light,military project, aluminum zinc die casting parts,auto parts, mechanical equipment parts, food machinery parts, building hardware parts, ship hardware parts, kitchen supplies, medical equipment, sports equipment parts,steel mould,stainless steel products, traffic spare part, display frame, cable car fittings, electricity facilities,sewing machine accessories, hardware parts, plastic products,copper processing, ashtry alloy, bakeware hardware,radiator, aluminium alloy joint, bullet train dashboard, engineering machinery, new energy accessories,mechanical accessories,bracket assembly, LED lampholder,speaker accessories, power clip tool mechanical,PE equipment accessories,motor tube,air duster gun metal part,pump part, aluminium boat yacht accessories,industrial mechanical accessories,etc.In a word, we can make all mechanical accessories in this business field.So need to do better service.

Q1. Are you a factory or trade company?

A: We are a factory with over 28 years of gravity casting,high pressure die casting,low-pressure casting,Cold Extrusion (Aluminum&Copper),Stainless Steel (Precision Casting)and Silica Sol Casting. We service customers 3D drawings,aluminum die casting mold design, die casting, machining, surface treatment, packing and shipping all over the world.

Q2. Where is your factory?

A: Our factory located in No. 1, Bianjia, Yanshan Village, Yinjiang Town, Haishu District, Ningbo,Zhejiang Province, China

Q3. How to get a quotation?

A: Received the sample or 2D/3D drawings then we will provide the quotation.

Q4. What is your Payment terms?

A: Mold costs: 50% prepayment, balance after sample approval

Mass production: 30% prepayment, balance pay before delivery or as per discussion.

Q5.What is the lead time of mold and mass production?

A: Normally,it takes 30-45 days for bulk order and 30-60 days for the parts.Both product size and structural complexity affect manufacturing time.

Q6. How about the packing?

A: Standard or customized will both be available. B.How to guarantee the quality of your products?

1) Strict detection during production.

2) Strict sampling inspection on products before shipment and intact product packaging ensured.

Q7.What about your quality control?

A: Checking the raw material after they reach our factory-----Incoming quality control(IQC)

B: Checking the details before the production line operated

Have full inspection and routing inspection during mass production----In-process quality control(IPQC)

C:Checking the goods after they are finished----Final quality control(FQC)

D:Checking the goods after they are finished----Outgoing quality control(QC)

E.100% inspection and delivery before shipment.

Q8:Why choose us?

A.OEM & ODM

B.28 years manufacture experience

C.Our clients are in over 38 different countries all over the world.

![]()

![]() Sherry Shu

Sherry Shu

![]()

![]() +(86) 135 0674 0524

+(86) 135 0674 0524

Похожие товары

Изготовленный на заказ профессиональный литой чугун из нержавеющей стали для инвестиций алюминиевый сплав для латунных медных материалов

Высокоточное литье из нержавеющей стали

Вакуумное литье под заказ

TS16949, Заводская чугунная рама, алюминиевая цинковая отливка, Полировочная лампа, детали корпуса алюминиевого электродвигателя

Железная решетка, алюминиевый маховик, система хранения энергии, литье под давлением, форма для наковальни, кузнечная сталь, алюминиевый литой

Набор литой алюминиевой посуды

Недорогие и качественные Литые детали из нержавеющей стали от производителя во Вьетнаме

Новые поступления

Новинки товаров от производителей по оптовым ценам