От 1 до 5 лет по заводской цене

- Категория: >>>

- Поставщик: Zhengzhou Lung Yeuk Machinery CO. Ltd

Сохранить в закладки 1601173373925:

Описание и отзывы

Характеристики

Factory price 1-5t/h Turn-key project small scale CPO palm fruit oil press line palm oil machine

Our factory supply small commercial palm oil press machine from 1t/h to 5t/h. It is suitable for business starting.

1,Compendium

We adopt advanced equipments,they have many kinds of characters,such as continuelly automatic operation,steady running,low noise and reliable performance.

2,Specification and raw material

To achieve the above-mentioned standard losses, the fresh fruit bunches (FFB) are processed for meeting Standard Maturity, TBS as follows:

Unripe : 0 %

Underripe : < 5 %

Ripe : > 85 %

Overripe : < 5 %

Empty Bunch : < 1 %

Part henocarpic : < 1 %

Hard Bunches : < 3 %

3. Standard Desain

3.1.CPO Quality :

Moisture in produced oil : < 0.50 %

Dirt in produced oil : < 0.1 %

3.2. CPO Yield and Losses (% to FFB):

Average Yield of CPO : > 18% Avery

Total losses < 1.14 %, listed:

Press cake : < 0.82 %

Nut : < 0.06 %

Fruit in empty bunch : < 0.03 %

Empty bunch : < 0.50 %

Unstripped Bunch : < 0.03 %

4,Process flow and description of the process ( we supply for the Aoto CAD drawing after paying the designing fees )

FFB(Palm fruit bunches)--Sterilizing--Thershing--Digesting--Pressing--Clarifying--DryingFiltering----Crude palm oil

Main technical specification of palm oil machine

Sterilizing section of palm oil machine: adopt hot water for boiling the FFB ,which loosen the contacts between fruit and bunch .

fresh palm fruit bunch are sterilized in sterilizer with steam. The purpose to prevent enzymes broken down, avoiding FFA content in oil further increase; pretreatment peel, prepared for the follow-up processing; pre-conditioning stone, reducing the damage kernel.

Thresher process of palm oil machine

The purpose of threshing is the oil palm fruit be separated from the fruit bunch through strong vibration, Threshing equipment is revolving drum thresher. The oil palm fruit separated be ejected then into the press section. Empty fruit bunch be ejected to the yard from the other side of the revolving drum, or shipped out from the plant as palm orchards slipcover to recycling use, or burning in the locale as fertilizer for agricultural land.

Digester of palm oil machine

It is used to release the palm oil in the fruit by breaking down the oil-bearing cells. The palm oil digester design includes a heated cylindrical container equipped with a central rotating rod carrying some stirring or beating arms. These rods pound the palm fruit at high temperature to reduce the thickness of the palm oil and to remove the excerpt, which is the hard outer covering of the palm fruit.

The palm fruit digester machine fills from the thresher, and it is important to match the capacity of the harvester to the palm oil digester machine. The digester runs optimally when it is full or at least three quarters full. It takes about 15 minutes for the palm oil digester machine to process a single batch from the thresher.

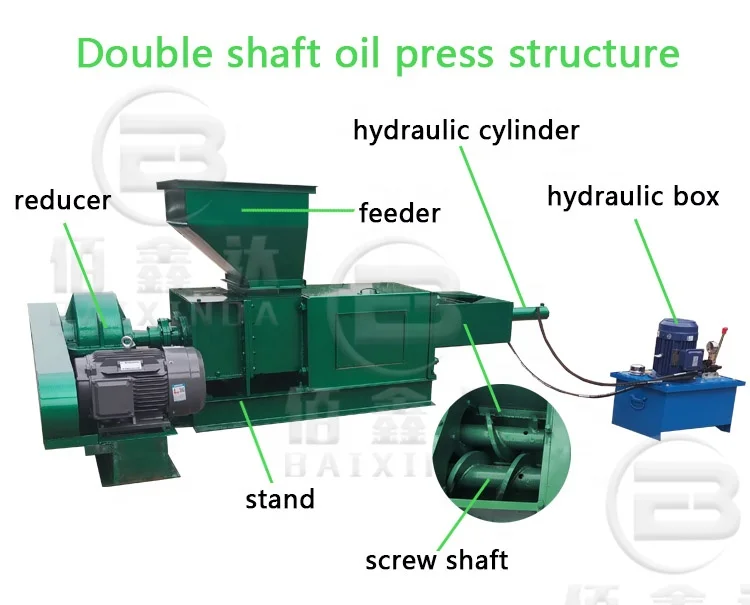

Pressing section of palm oil machine: Palm fruite enter into continuous screw press for pressing. Oil palm fruit pressed is divided into two parts: oil, water, solid impurities mixture and the press cake (fiber and nuclear). Oil, water, solid impurities mixture by the crude oil gutter inflow to oil purification section; press cake by breaking screw conveyor into the fiber- recovery section.

The process adopts the special screw oil press ,so the palm nut is out with the dregs without damaging .

Vibratile sieve of palm oil machine

It adopts the vibrate sieve to remove out the dregs,fibre from the crude oil and the crude oil should be quickly filtered or it would be cool, the oil would become fat, total 3 lyaers,and different mesh of the sieve, after the third sieve, the crude oil is very cleaner .

Clarification section of palm oil machine: The crude oil first diluted with water washing, through settlement and filtration, the fiber material removed from the oil, and then carries out continuous settlement, the whole divided into two parts: oil and sediment. Oil is filtered and through the pump pumped into the storage tank for storing; oil sediment is filtered and dirt oil separation, oil processed is for the second settlement, dirt oil mixture process clarification separation, Skim oil then carry out a second settlement, sewage pumps to sewage treatment pond for dealing with.

Oil tank and oil loading shed

To store the CPO and prepare for loading cpo to the other place.

Loading into Container at port

Q: If I don't know how to operate this machine? How can I do?

A: Our machine has been tested OK and fully assembled before shipping, customer just needs to make2~4 hours wear-in and then can work.

Q: What can I get the price?

A We usually quote within 2 hours after we get your inquiry. If you are very urgent to get the price, please tell us in your email so that we will regard you inquiry priority.

Q: How can I get the sample to check your quality?

A After price confirmation, you can require for samples to check our product’s quality.

Q: What is your term of delivery?

A :We accept EXW, FOB Qingdao. You can choose the one which is the most convenient or cost effective for you. Best palm fruit oil press, palm kernel oil press and other palm oil line machines.

Q: Can I be a distributor of Lung Yeuk palm oil press?

A: Of course you can.

Q: What are the benefits of being a Lung Yeuk distributor?

A: - Special discount . - Marketing protection. - Supporting of marketing development - Point to point technical supports and after sales services.

Q: How can i become a distributor of Lungyeuk?A: Contact us immediately for further details by sending us an inquiry.

Client visit

Похожие товары

5 т/д физическая машина для переработки хлопкового масла пальмового с дезодорированием от обесцвечивания

Машина для производства пищевого масла подсолнечного соевого орехового мини-нефтеперерабатывающее оборудование пальмового

Проект «под ключ» бесплатный дизайн для оборудования производства пальмового масла оборудование линия прессования

Машина для экстракции пальмового масла

Коммерческая масляная пресс-машина для прессования пальмового масла

Комбинированная машина для обработки пальмового масла растительное пальмовое масло распродажа

Мини-TMS-898 для домашнего использования 720 Вт

Новые поступления

Новинки товаров от производителей по оптовым ценам