Производитель литья под давлением специализирующийся на пресс форме для автомобильных прямоугольных телескопических контейнеров хранения с герметичными крышками

- Категория: >>>

- Поставщик: Kunshan Mai Feng Precision Industry Co. Ltd.

Сохранить в закладки 1601207200942:

Описание и отзывы

Характеристики

Successful Project

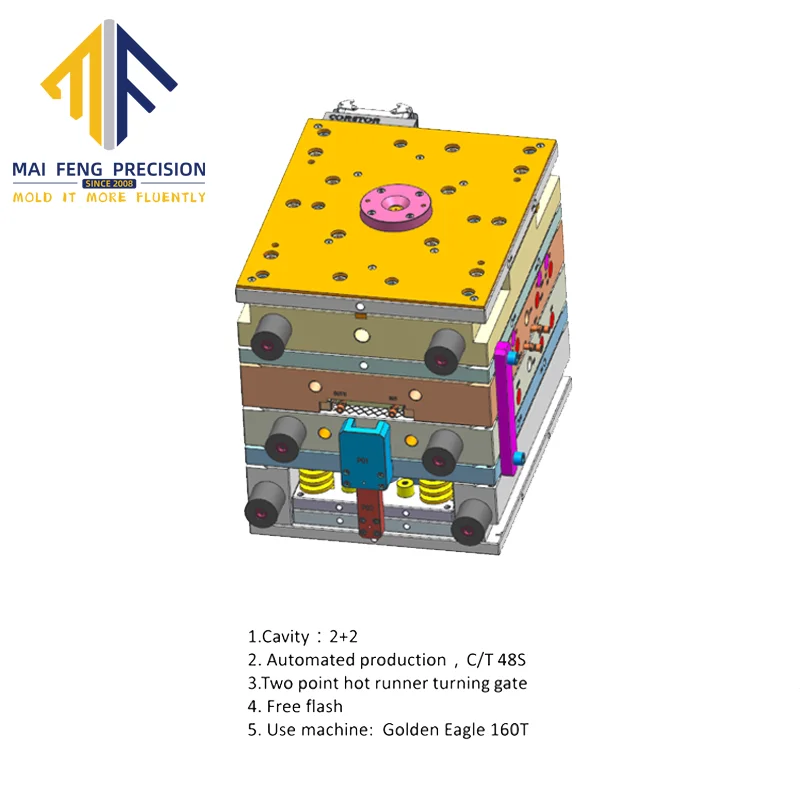

Technical Parameters

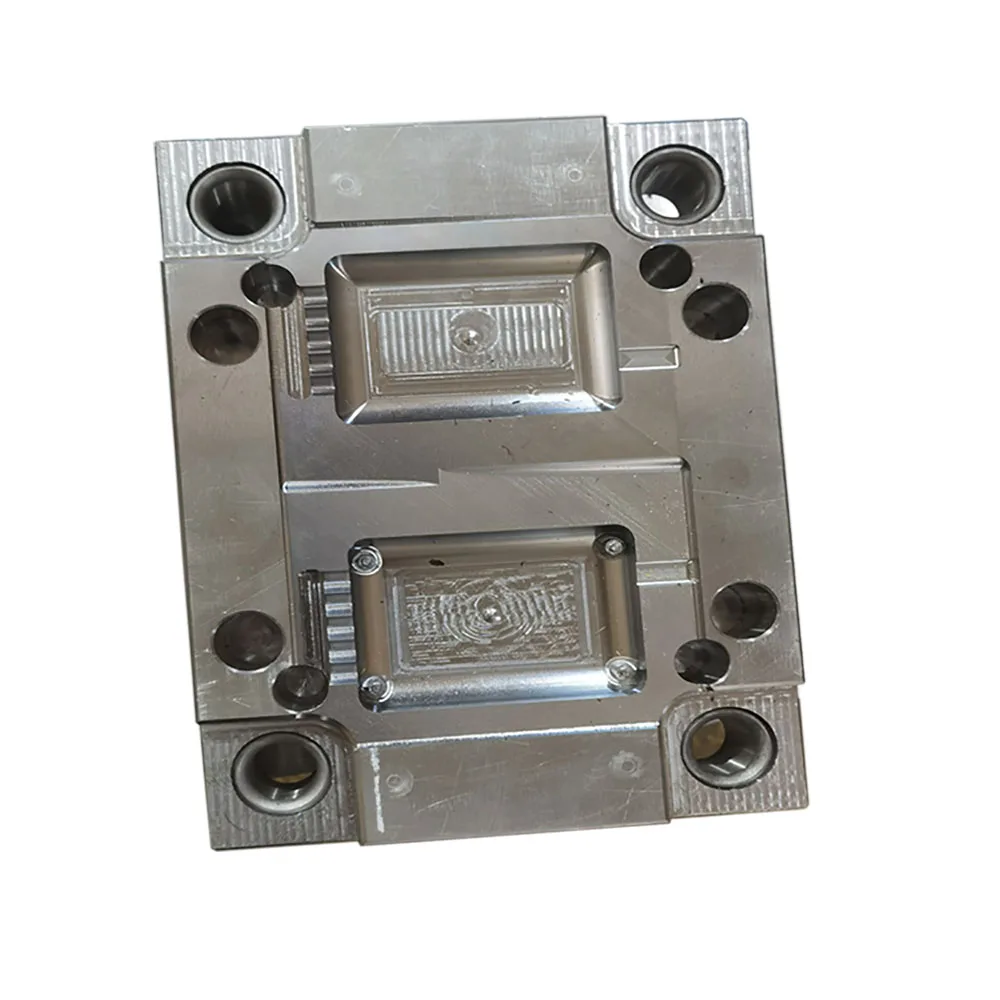

1. Cavity: 2+2

2. Automated production, C/T 48S

3. Two point hot runner turning gate

4. Free flash

5. Use machine: Yizumi 160T

2. Automated production, C/T 48S

3. Two point hot runner turning gate

4. Free flash

5. Use machine: Yizumi 160T

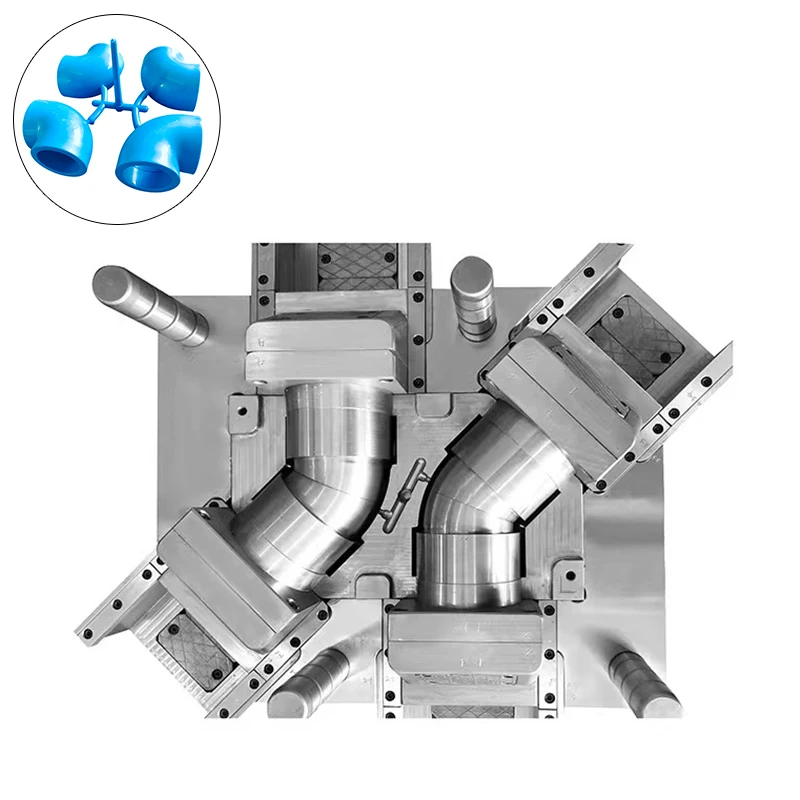

Technical Parameters

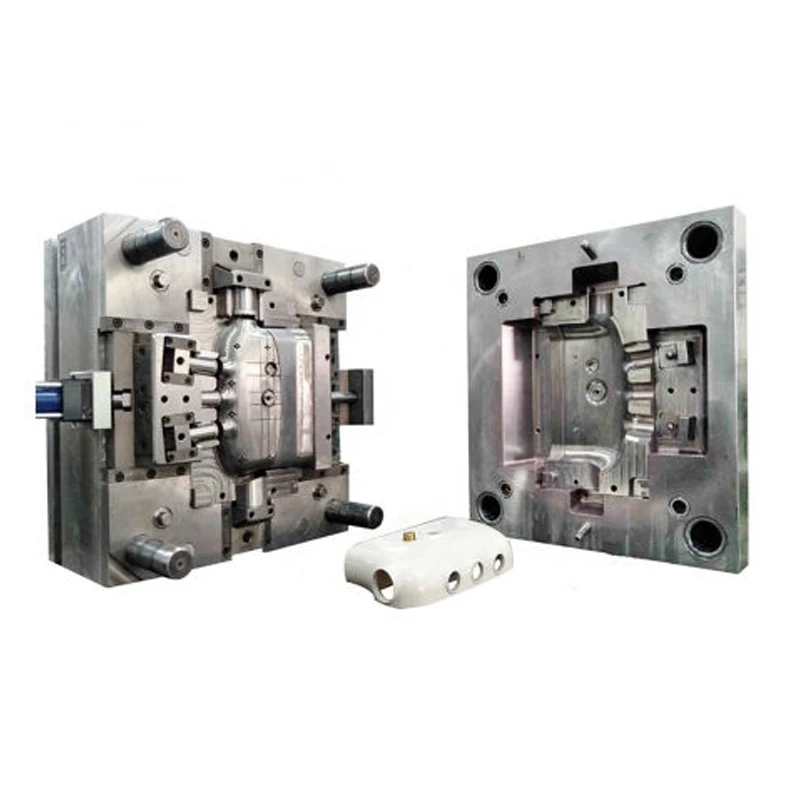

1. Cavity: 1+1

2. Automated production, C/T 50S

3. Two point hot runner

4. Free flash

2. Automated production, C/T 50S

3. Two point hot runner

4. Free flash

5. Use machine: Yizumi 120T

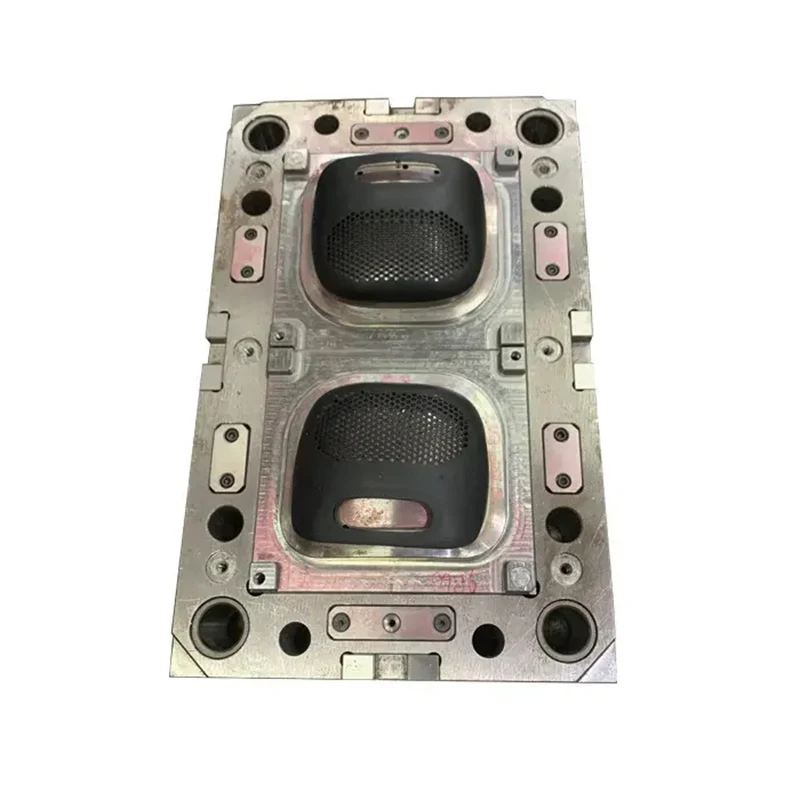

Technical Parameters

1. Cavity: 1

2. Automated production, C/T 50S

3. One point open hot runner inclined top submerged pouring

4. Free flash

5. Use machine: Yizhi 90T

2. Automated production, C/T 50S

3. One point open hot runner inclined top submerged pouring

4. Free flash

5. Use machine: Yizhi 90T

Technical Parameters

1. Cavity: 1

2. Automated production, C/T 35S

3. One point open hot runner rotary gate

4. Free flash

5. Use machine: Haitian 130T

2. Automated production, C/T 35S

3. One point open hot runner rotary gate

4. Free flash

5. Use machine: Haitian 130T

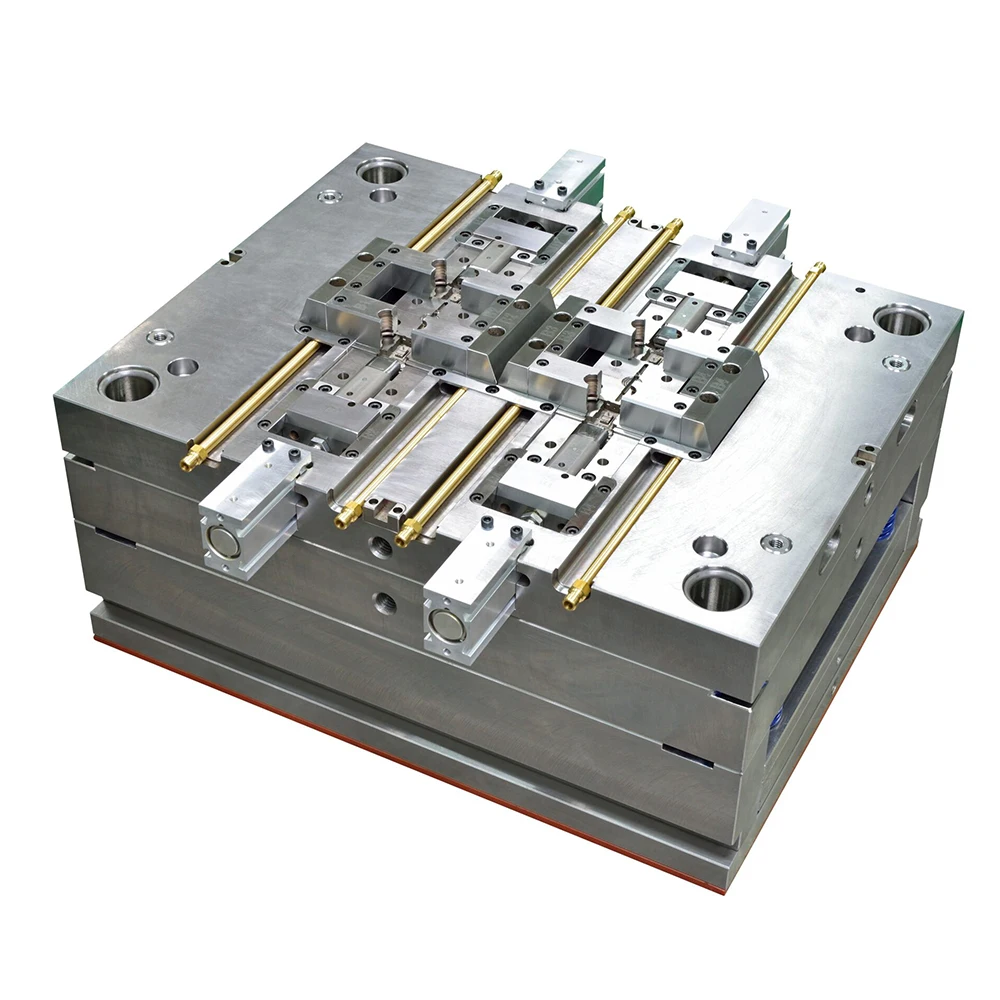

Technical Parameters

1. Cavity: 1

2. Automated production: C/T 50S

3. Two point open hot runner to two point submerged gate + one point tip hot runner

4. Free flash

5. Use machine: Yizumi 300T

2. Automated production: C/T 50S

3. Two point open hot runner to two point submerged gate + one point tip hot runner

4. Free flash

5. Use machine: Yizumi 300T

Fully automatic

Fully automated production, saving labor costs

Good material quality

Highly polished and corrosion-resistant mold steels such as 1.2083 and S136

Longevity

Customized lifespan of 1-5 million cycles

Short cycle

Short molding cycle and high yield rate

1、Reasonably concealed gate location

Indicating that the gate location is designed to be inconspicuous or hidden in a way that

does not affect the appearance or function of the final product.

does not affect the appearance or function of the final product.

2、Exture (a surface treatment for mold surfaces to create a specific pattern or texture)

Multiple texturing processes available, with even and fine texture patterns.

3、Parting line (the line where the two halves of a mold come together to form the cavity)

The visible but not touchable parting line on the exterior, near-zero parting line on the rotating insert, and clear color

division boundary without burrs.

4、Appearance

Resolve issues such as air traps, flow marks, stress marks, etc.

Multiple texturing processes available, with even and fine texture patterns.

3、Parting line (the line where the two halves of a mold come together to form the cavity)

The visible but not touchable parting line on the exterior, near-zero parting line on the rotating insert, and clear color

division boundary without burrs.

4、Appearance

Resolve issues such as air traps, flow marks, stress marks, etc.

Company Profile

About US

Kunshan Maifeng Precision Industry Co., Ltd.(MIF) , with an investment scale of 35 million yuan, has a more than 5000 ㎡ independent factory, 25 single and dual color injection molding machines with a capacity of 90-700 tons, over 50 units mold processing equipment, and a service management and production team of over 100 people. We specialize in product design, mold manufacturing, injection molding, and product assembly for various types of plastic parts. Our parent company was established in 2008, with amature and experienced team, providing customized and differentiated services for small and medium-sized customers both domestically and internationally.

1. Product Design

We can conduct product structure design and optimization based on the provided drawings and samples.

2. Mold Design

Based on customer requirements, select an appropriate mold design scheme.

3. Mold Manufacturing

One-stop processing including machining, polishing, assembly and other processes for mold parts.

4. Injection Molding

Single/double-color injection molding machines to meet customer order requirements.

5. Product Assembly

Production Team

Service Team

Design Team

Certifications

Our Advantages

Design

3 senior process engineers.

6 mold design engineers.

An average of 20 years of industry experience.

Mold manufacturing

18 mechanical processing engineers.

2 Japanese Makino mirror EDM machines.

4 German OPS 5-axis high-speed machining centers.

Quality-inspection

5 quality control engineers.

Hexagon three-dimensional inspection equipment from the United States.

Precision 2.5D inspection equipment.

Equipment Brand | Device Model | Origin Place | Operating Range(mm) | Quantity |

OPS 5-Axis High-Speed CNC | OPS550 | Germany | 550*400*400 | 2 |

OPS 5-Axis High-Speed CNC | OPS750 | Germany | 1100*750*500 | 2 |

Makino EDM | EDGE2i | Japan | 300x250x250 | 1 |

Makino EDM | EDGE3i | Japan | 450x300x320 | 1 |

EDM | S550 | Taiwan, China | 500x400x300 | 1 |

EDM | DE-45 | Taiwan, China | 450x350x300 | 2 |

NC | MV-1380B | Taiwan, China | 1300x800x800 | 1 |

NC | MV-850B | Taiwan, China | 900x500x500 | 1 |

NC | VM900 | Taiwan, China | 900*500*400 | 1 |

High-speed Precision Engraving Machine | JTGK-600iplus2 | Taiwan, China | 465*600*300 | 1 |

High-speed Precision Engraving Machine | SD-543 | Taiwan, China | 500x400x300 | 1 |

Slow Traveling Wire EDM | HP-500 | Taiwan, China | 500x300x265 | 1 |

Slow Traveling Wire EDM | G32S | Taiwan, China | 400x250x215 | 1 |

Piercing Machine | DB-703 | China | 300x250x300 | 1 |

Grinding Machine | BSG-818M | Taiwan, China | 470x180x410 | 3 |

Turret Milling Machine | KN-4S | Taiwan, China | 820x420x500 | 2 |

Lathe | CH430-800 | CH430-800 | 470x180x410 | 1 |

equipment Brand | Machine Tonnage(T) | Forming Method | Horizontal /Vertical Machine | Maximum Shot Weight(g) | Quantity |

FCS Injection Molding Machine | 160 | Two-Color Injection Molding | Horizontal Machine | 66+66 | 1 |

FCS Injection Molding Machine | 280 | Two-Color Injection Molding | Horizontal Machine | 77+146 | 2 |

FCS Injection Molding Machine | 400 | Two-Color Injection Molding | Horizontal Machine | 185+289 | 1 |

FCS Injection Molding Machine | 700 | Two-Color Injection Molding | Horizontal Machine | 414+185 | 2 |

Niigata Injection Molding Machine | 450 | Single-Color Injection Molding | Horizontal Machine | 400 | 3 |

Yizumi Injection Molding Machine | 450 | Single-Color Injection Molding | Horizontal Machine | 800 | 2 |

Yizumi Injection Molding Machine | 90 | Single-Color Injection Molding | Horizontal Machine | 110 | 1 |

Haitian Injection Molding Machine | 350 | Single-Color Injection Molding | Horizontal Machine | 473 | 2 |

Haitian Injection Molding Machine | 650 | Single-Color Injection Molding | Horizontal Machine | 1580 | 1 |

Haitian Injection Molding Machine | 130 | Single-Color Injection Molding | Horizontal Machine | 200 | 2 |

Haitian Injection Molding Machine | 160 | Single-Color Injection Molding | Horizontal Machine | 300 | 2 |

Haitian Injection Molding Machine | 300 | Single-Color Injection Molding | Horizontal Machine | 700 | 2 |

Haitian Injection Molding Machine | 200 | Single-Color Injection Molding | Horizontal Machine | 246 | 2 |

Fengtie Injection Molding Machine | 40 | Single-Color Injection Molding | Vertical Machine | 89 | 2 |

Equipment Brant | Device Model | Origin | Operating Stroke | Quantity |

Hexagon CMM | CROMA-8106 | America | 800x1000x600 | 1 |

2.5D Measurement Equipment | WHE-4030V | Taiwan, China | 400x300x200 | 1 |

Mitutoyo Height Gauge | LH-600E | Japan | 600 | 1 |

Projector | PB-3020-200 | Taiwan, China | 300x200x200 | 1 |

Rockwell Hardness Tester | HR-J150A | China | 170 | 1 |

Torque Testing Machine | HP-100 | China | 1.5~90.0bf.in 1.5~100.0kgf.cm 0.15~10.00N.m | 1 |

Coating Thickness Gauge | CT-100 | China | 0-1250um/0-50mil | 1 |

Location

MIF(Mold It More Fluently) company is located in Kunshan, Jiangsu, adjacent to Shanghai(15 minute journey).

The transportation is very convenient . We warmly welcome you & your company to visit and inspect our factory.

Plane: Shanghai Hongqiao Airport

high-speed rail: Kunshan South Station

Car: Navigation Kunshan Maifeng Precision Industry Co., Ltd

Taxi: Across from the West Gate Of Luxsan Precision iTech (Kunshan) Co., Ltd.

Plane: Shanghai Hongqiao Airport

high-speed rail: Kunshan South Station

Car: Navigation Kunshan Maifeng Precision Industry Co., Ltd

Taxi: Across from the West Gate Of Luxsan Precision iTech (Kunshan) Co., Ltd.

FAQ

Q1: Are you a factory or trading company?

MIF is plastic mold and injection molding manufacture in China, welcome to visit us.

Q2: How can i get the quotation?

We will submit the quotation in 24 hours if getting detailed information during working days. In order to quote for you earlier, please provide us the following information together with your inquiry.

1). 3D Step of Files and 2D Drawings;

2). Material requirement;

3). Surface treatment;

4). Quantity (per order/per month/annual);

5). Any special demands or requirements, such as packing, labels, delivery, etc.

Q4: What should we do if we receive defective products?

If receive defective product, please send us the photos, we will feedback to ourengineers and QC departments and solve the problems ASAP.

Q5: How to pack the moulds and products?

1). For moulds, we will be coated one-layer anti-rust oil first, and then also will be covered thin films on the mould, finally

pack into fumigation wooden case.

2). And as to products, we will pack into standard export cartons or as per customer's request to pack.

MIF is plastic mold and injection molding manufacture in China, welcome to visit us.

Q2: How can i get the quotation?

We will submit the quotation in 24 hours if getting detailed information during working days. In order to quote for you earlier, please provide us the following information together with your inquiry.

1). 3D Step of Files and 2D Drawings;

2). Material requirement;

3). Surface treatment;

4). Quantity (per order/per month/annual);

5). Any special demands or requirements, such as packing, labels, delivery, etc.

Q3: How you do the quality control?

1). Materials inspection by IQC;

2). During processing, our IPQC will check the injection molded parts every;

3). Hours, ensure no any rejects;

4). FQC will check the products before sending to the warehouses;

5). 100% inspected by QC before shipping out.

1). Materials inspection by IQC;

2). During processing, our IPQC will check the injection molded parts every;

3). Hours, ensure no any rejects;

4). FQC will check the products before sending to the warehouses;

5). 100% inspected by QC before shipping out.

Q4: What should we do if we receive defective products?

If receive defective product, please send us the photos, we will feedback to ourengineers and QC departments and solve the problems ASAP.

Q5: How to pack the moulds and products?

1). For moulds, we will be coated one-layer anti-rust oil first, and then also will be covered thin films on the mould, finally

pack into fumigation wooden case.

2). And as to products, we will pack into standard export cartons or as per customer's request to pack.

Похожие товары

Пользовательская высокоточная машина для литья под давлением силиконовая резина экструзия выдувание формы изготовление пластиковых форм

109 648,40 ₽

Высококачественный матовый ПК + АБС-динамик пластиковая литьевая форма для литья под давлением индивидуальная коробка динамиков

767 538,80 ₽

Изготовленная на заказ монета штампы для ноутбука корпус динамика коробка пластиковая инъекционная Ручка Форма в форме сердца

2 083,32 ₽ - 4 385,94 ₽

Силиконовые формы для мыла силиконовые из тайваньской кремниевой жидкости изготовления форм

Модная пластиковая литьевая форма для очков

Изготовленная на заказ форма для литья под давлением пластиковая очков от китайского производителя

54 824,20 ₽ - 219 296,80 ₽

Изготовленные на заказ солнцезащитные очки силиконовая форма пластиковая литьевая косметика для электроники

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $