Дешевая и качественная производственная линия порошка гипса/штукатурки

- Категория: >>>

- Поставщик: Henan Dafu Mechanical Import And Export Co. Ltd.Henan Ltd.

Сохранить в закладки 1601238995192:

Описание и отзывы

Характеристики

Cheap and good quality gypsum/plaster powder production line

1.Introduction of the gypsum powder production line:

With the development of gypsum industry, the need for quantity and quality of gypsum powder is increasing rapidly. At the same time, the proceeding for producing gypsum powder had enhanced gradually. In the process of gypsum powder production, drying and dewatering is the key link, which is also the most difficult part to control. In order to solve this problem, ebullience calciner, a new type of drying and dewatering equipment has been designed, which is produced based on the exploring of the gypsum production filed. Following is the brief introduction of the gypsum production technology and working principle of ebullience calciner.

2.Supplying Capability

Capability | 10,000 tons/year~300,000 tons/year |

Automation | fully automatic |

Calcination system | using boiling furnace to calcine adopting heat conductive oil furnace as heat source |

Energy consumption | coal, natural gas, heavy oil, diesel oil |

Main materials | natural gypsum rock, desulfurization gypsum, dephosphorizaiton gypsum |

Standard of product quality | In conformity with national standard “GB/T 9776-2008 construction gypsum“ |

3.Obvious Advantages

(1) Simple and sustainable structure

fluidization material, funace doesn't need rotatable component , it easy to built and almost free of maintenance.

low temperature heat source, the furnace won't be damaged by over heating and has longer operating life.

(2) Compact design and less space requirement

vertical arrangement, the dust catcher on the top of the furnace body is integrated with the boiling furnace compactly. both save space and avoids condensation of the dust collecting system.

(3) Low energy consumption

The heat energy, is almost all used for material's dehydration.

the steam boilers or hot oil boilers are boilers, efficiency can reach 60-70% and the oil boiler's can reach 70-80%.

our company uses organic heat carrier hot oil boiler(heating conduction oil boiler). with steam,it can reach 57-67%,it can reach 67-76%.

(4)Reliable quality, ideal compositions of Paris Powder, stable Physical properties

low temperature heat source, the plaster does not tend to be over calcined. only if controlling the discharte gypsum and with less than 5% anhydrite. and the spare is all hemihydrate gypsum.

this composition is very ideal and with stable physical property.

The most appropriate price, to provide the best quality products and services to establish long-term relationship with our customers.

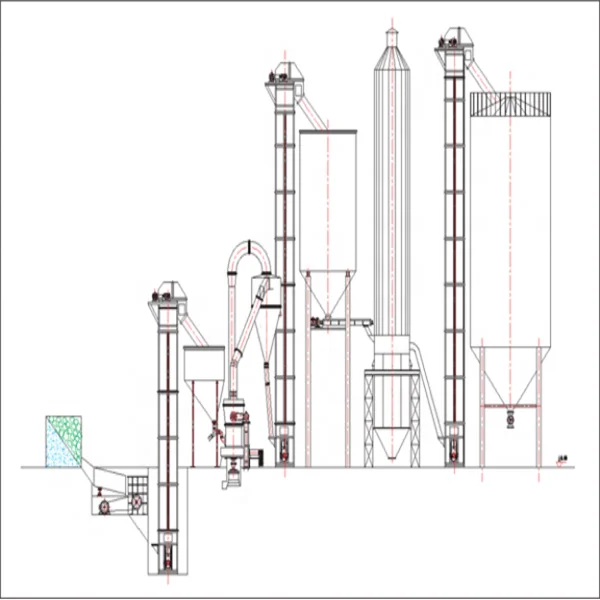

Gypsum powder production line flow chart:

gypsum powder production line for construction materialis composed of crusher, Raymond mill, lifter, dust remover, heat conductive oil furnace, Roots fan, material bin etc.

Gypsum powder mill

Raymond Mill is applicable to the grinding and processing of more than 280 kinds of non-flammable and non-explosive materials with hardness less than 7 and humidity less than 6% in mining, construction, chemical industry and metallurgy, such as barite, calcite, feldspar, talcum, marble, limestone, clay, glass. The fineness of the finished product can be adjusted from 100 mesh to 325 mesh according to requirements.

New-type gypsum frying boiler- ebullience calciner

First grind and second bake. The largest advantage of this technique, compared with that of “first bake and second grind”, is energy consumption reduction. Large plaster stone shall be ground into powders with diameter less than 0.2mm, which increases the specific surface when calcining, enlarges the contact area with heat medium, improves calcinations heat exchange efficiency and lowers energy consumption greatly. This equipment has small bulk, large production capacity, and simple structure and is hard to destroy.

Electrostatic dust collector

itworks is to use of high-voltage electric field to ionize the flue gas, charged dust in the air flow in the electric field and the flow separation. , Called the discharge electrode, a negative electrode is made by the different cross-sectional shape of the metal wires. The positive electrode is made of a different geometric shape of the metal plate, called the collecting electrode. Electrostatic precipitator performance by the three factors of the dust characteristics, device structure and the flue gas flow rate. The specific resistance of dust is to evaluate the conductivity indicators, and its removal efficiency has a direct impact. The specific resistance is too low, dust is difficult to maintain on the collecting electrode, resulting in its return to the stream. Specific resistance is too high to reach the dust charge of collecting electrode is difficult to release, in the voltage gradient is formed between the dust layer will produce a partial breakdown and discharge phenomenon. These conditions will result in the removal efficiency decreased.

Main characters of heat-conducting oil boiler :

1. High automaticity, prompt start and stop, high reliability.

2. High thermal efficiency, completely burning, stable output, better adaptability to variable load.

3. Compact structure, small area requirement.

4. Less auxiliaries, easy installation.

5. Less pollutant emission, can reach higher Environmental protection index.

Electrical control system

The current advanced DCS(distributed control system) is selected for the electrical control system, and the PLC is chose from Japan’s Mitsubishi company, which could centralized control equipment that scattered in different parts. It becomes the first choice for modern building industry due to low labor, cost and high efficiency.

Electromagnetic feeder

Elevator

Screw conveyor

Pre-sales Service

1.Offering comprehensive technical and business consultation services;

2.Proposing the most suitable scheme and equipment for our clients;

3.Designing and fabricating targeted products according to the special requirements of clients;

Service on Sale

1.Providing initiative and enthusiastic service;

2.Introducing & Demonstrating products and its application to clients;

3.Helping clients to choose equipment.

After-sales Service

1.Highly inspecting equipment in every working procedure, quality comes first;

2.Fast & Safe Delivery;

3.One-year warranty

4. Assisting our clients for foundation construction of equipment;

5.Dispatching engineers to install and debug equipment;

Henan Dafu Mechanical Import and Export Co. Ltd. , located in Zhengzhou,Henan province, is specialized in manufacturing with more than 20 years’ development and running experience. With high career-honoring spirit and good servicing attitude by all staffs,our company won praise and recognition in the market.

If you want to learn more about our production and company ,please contact with me !

//dafumachinery.en.alibaba.com

Похожие товары

Машина для нанесения гипсового порошка/оборудование/Производственная линия

2024 новейшее высококачественное оборудование для производства гипсовых порошков

Производственная линия порошка гипса с минимальным вложением технологией горячего воздуха

Линия по производству гипсового порошка

Гипсовый порошок линия прокаливания Альфа гипсовый машина для гипсовой Штукатурки

Высокое качество YGM 75 гипсовый порошок завод мини raymond мельница для известняка доломита с классификатором

Самый недорогой гипсовый порошок Henan zhengzhou кальцинатор/машина для нарезки

Новые поступления

Новинки товаров от производителей по оптовым ценам