150 Вт QCW гальванометр лазерное сварочное оборудование новый дизайн лазерная сварка Настольный лазерный сварочный аппарат

- Категория: >>>

- Поставщик: Wuhan Questt Asia Technology Co. Ltd.

Сохранить в закладки 1601265686491:

Описание и отзывы

Характеристики

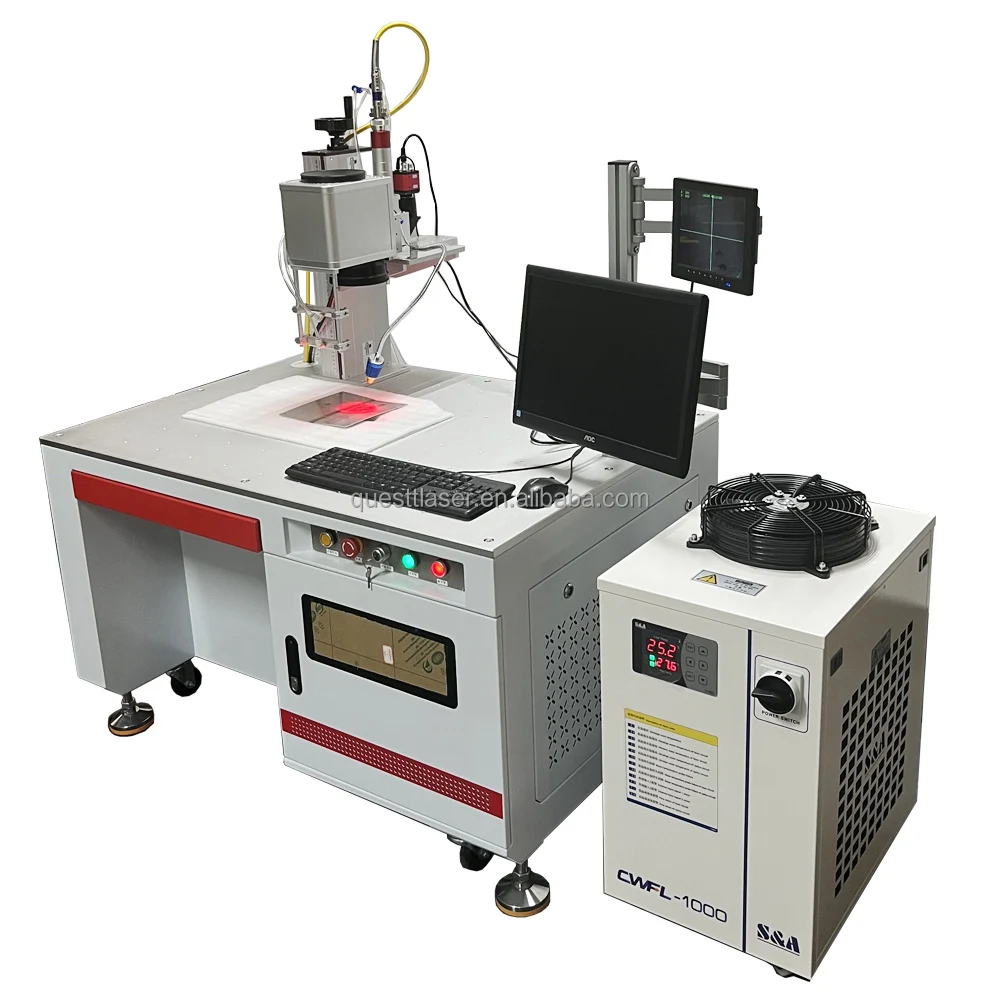

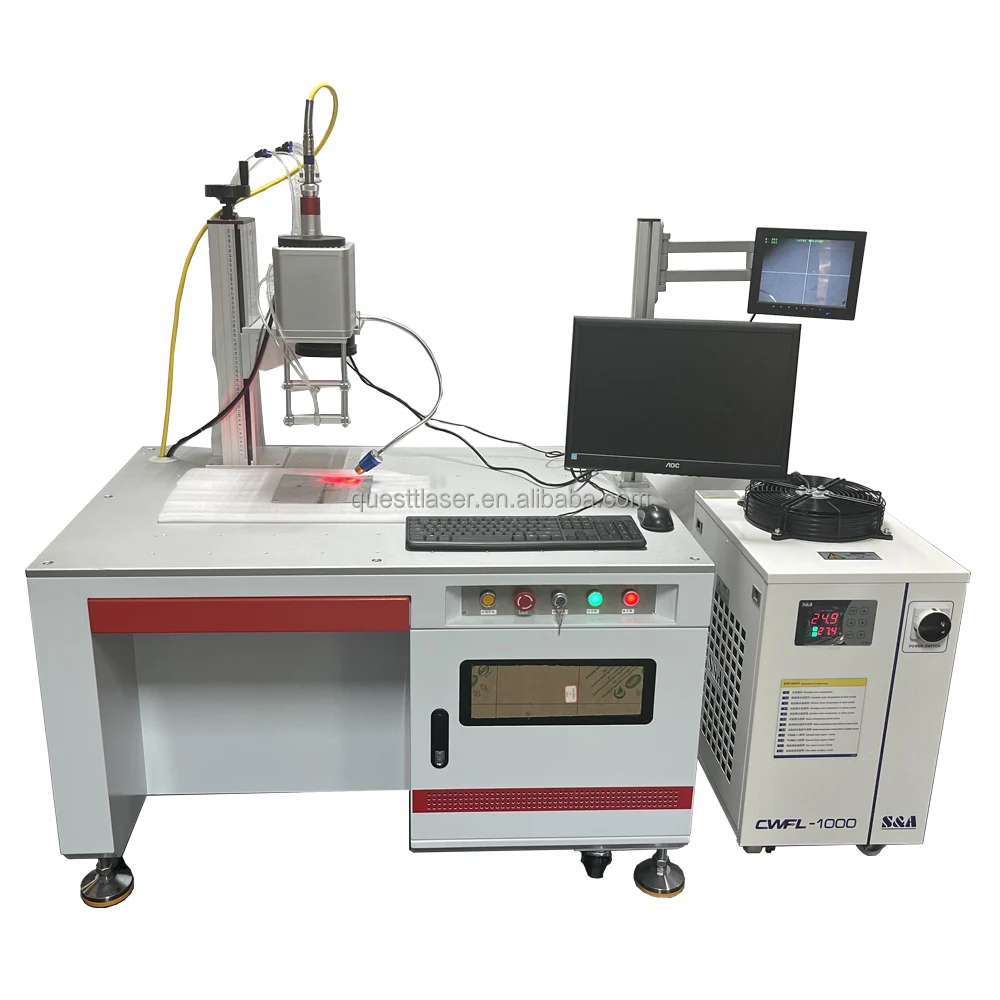

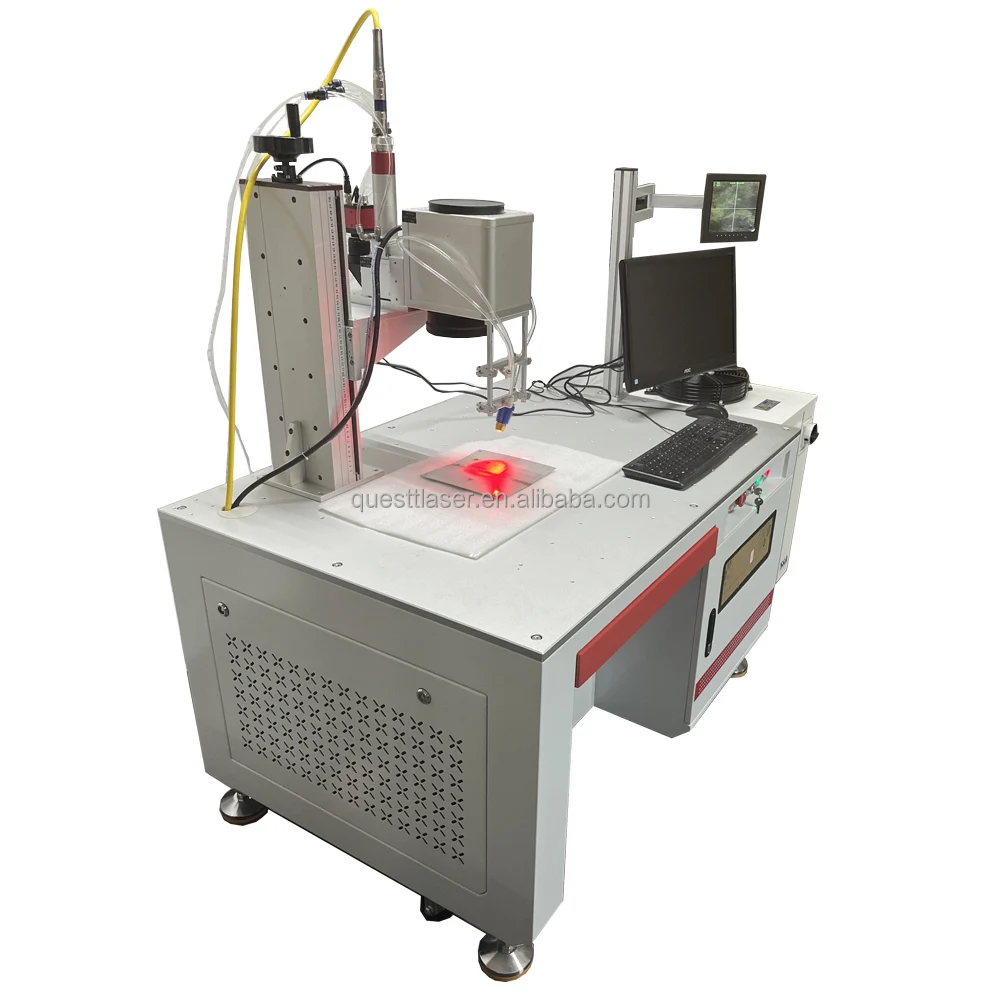

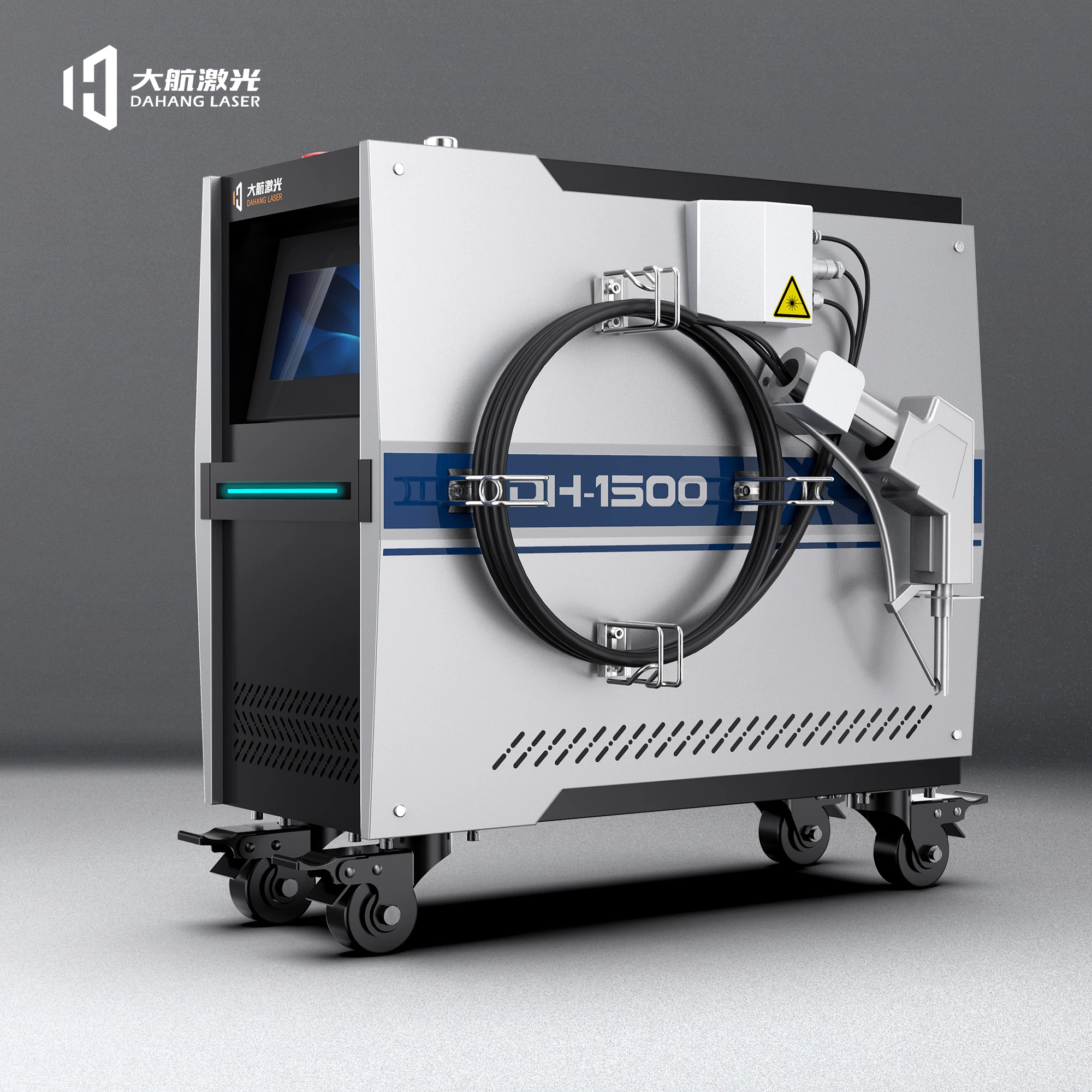

1000W 1500W 2000W Continuous 150W QCW Laser welder galvanometer laser welding equipment High precision laser welding machine

QA-CW1500 Laser welding System with Scanner | |||||||||||||||||||||||||||||||||||||||||||||||||

Model | QA-CW1500 | ||||||||||||||||||||||||||||||||||||||||||||||||

Laser Type | CW Fiber Laser | ||||||||||||||||||||||||||||||||||||||||||||||||

Laser Power | 1500W | ||||||||||||||||||||||||||||||||||||||||||||||||

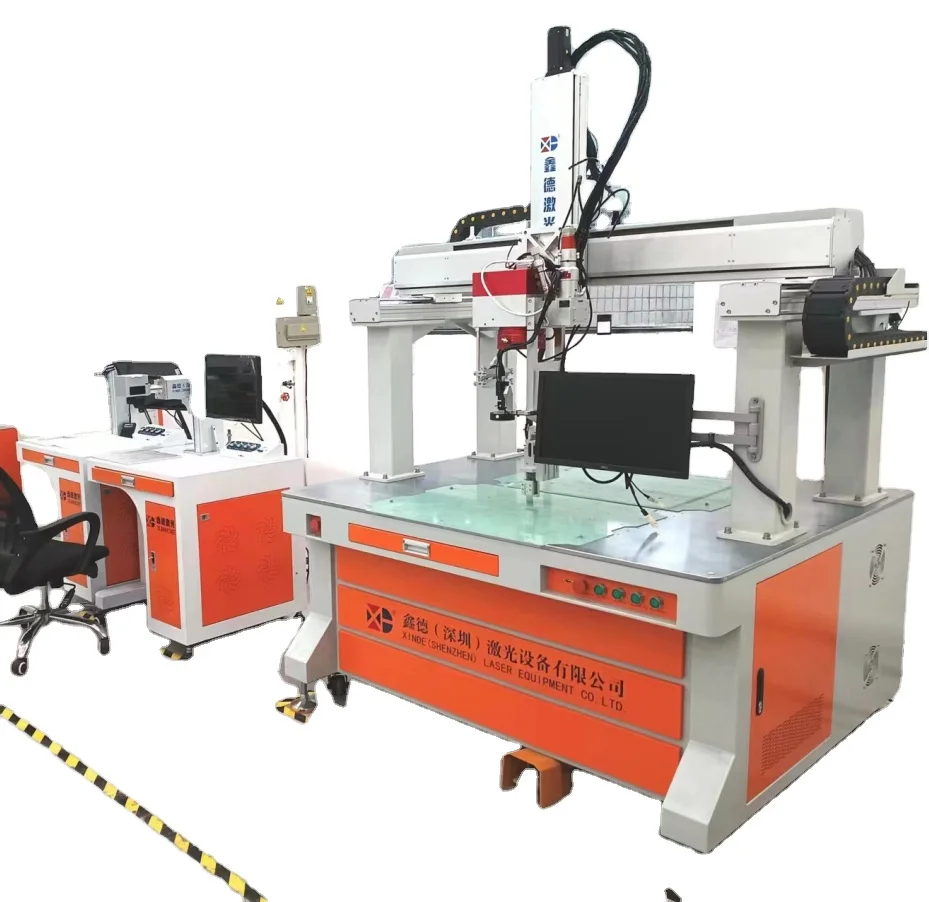

Machine Picture |

| ||||||||||||||||||||||||||||||||||||||||||||||||

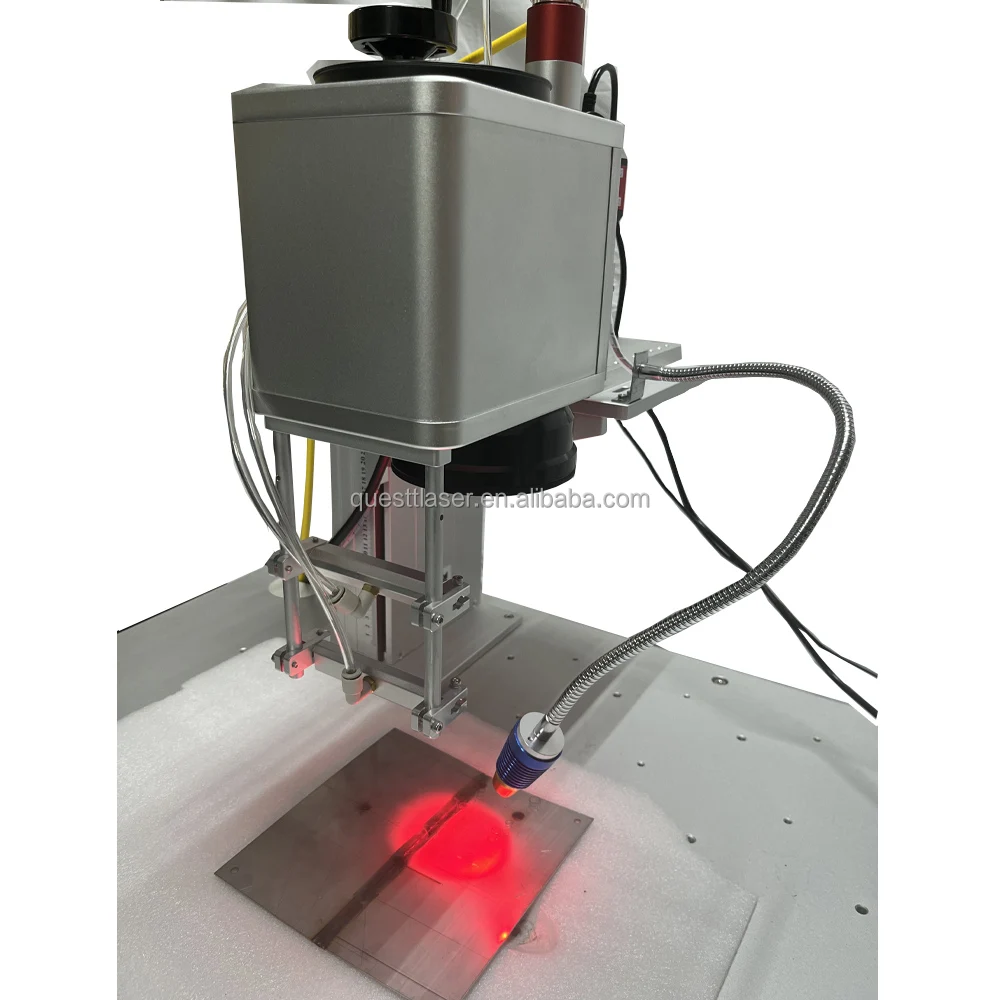

Galvanometer Head |

| ||||||||||||||||||||||||||||||||||||||||||||||||

Cooling System | Water Cooing Cooling power:1000W | ||||||||||||||||||||||||||||||||||||||||||||||||

Laser Source |

The CW Fiber Laser source has premium components,superior performance and longer lifetime 1. Up to 6KW output from cw single module series,better beam quality,multi module lasers,greatly improved efficiency. 2. Excellent material processing performance,high speed in thin sheet cutting,strong capability in thick material processing. 3. Compact design,maintenance free,highly integrated system with modular design,easy maintenance significantly reduce TCO. 4. Smaller size with higher stability,>60% reduction in volume,higher flexibility when integrated in to system. 5. High level vertical integration,all key components are designed and produced in house strict quality control,high consistency and reliability. | ||||||||||||||||||||||||||||||||||||||||||||||||

Function | QA-CW Laser welding System with Scanner is especially designed for the industry purpose with high precision welding and much less heat effect which is applied to weld precision products such as digital products, handsets, toys, autos, and motors mold making and modeling. It has long lifetime and high electro-optical efficiency with more deep and width welding result.

QA-CW Laser welding System with Scanner usually used in Automobile, Battery, Consumer Electronics, Sensor, Hardware & Home Appliance, Optical Communication, Flat Plate Solar Energy Collectors, Mold Repair Welding Machine, Laser Welding for Plastic, Laser Soldering & Brazing, Software, etc.

| ||||||||||||||||||||||||||||||||||||||||||||||||

Configuration | 1. 1500W CW fiber laser source 2. Stable Laser source Power supply 3. 20mm laser welding scanner 4. 1.5P laser chiller 5. Industry PC 6. CCD vision system 7. Special laser welding software 8. Special work-piece fixture 3 sets(Easy position) 9. Special laser welding program with spot welding and automatic welding as request 10. Laser welding cabinet 11. Spare parts 12. Operation Manual | ||||||||||||||||||||||||||||||||||||||||||||||||

Specification |

| ||||||||||||||||||||||||||||||||||||||||||||||||

System Dimension | L*W*H 880*1000*1150mm | ||||||||||||||||||||||||||||||||||||||||||||||||

Power Consumption | 7KW | ||||||||||||||||||||||||||||||||||||||||||||||||

Environment request | Temperature :10-40 degree | ||||||||||||||||||||||||||||||||||||||||||||||||

Payment Term | 50% T/T in advanced and 50% T/T Before Delivery | ||||||||||||||||||||||||||||||||||||||||||||||||

Delivery Time | 45 days | ||||||||||||||||||||||||||||||||||||||||||||||||

Guarantee Period | One Year | ||||||||||||||||||||||||||||||||||||||||||||||||

|

Sample

Похожие товары

10L15L 20L трубопровод Сварки Алюминиевой сварки из нержавеющей стали волоконно-лазерный гальванометр лазерный сварочный аппарат

Гибкая Точная сварка с помощью козлового гальванометра, литиевая батарея, лазерный сварочный аппарат с настраиваемым маршрутом

1500 Вт 2000 Вт 3000 Вт 4000 Вт 6000 Вт автоматический гальванометр лазерный сварочный аппарат дешевый Лучший волоконно-лазерный сварочный аппарат производитель

Гальванометр литиевая батарея Автоматический Лазерный Сварочный аппарат 1500 Вт лазерный сварочный аппарат с CCD-монитором

Литиевая батарея, гальванометр, 1500 Вт, 2000 Вт, 3000 Вт

CW волоконно-лазерная сварочная машина для ремонта пресс-форм, 3000 Вт, 2000 Вт, 1500 Вт, 1000 Вт, металлическая сталь, сплав меди, тип стрелы, лазерные точечные Сварщики

Портативный мини-сварочный аппарат для воздушного охлаждения maquina de soldar, светодиодная вывеска, легко перемещаемая лазерная сварочная машина, 1500 Вт, 2000 Вт, 220 В

Новые поступления

Новинки товаров от производителей по оптовым ценам