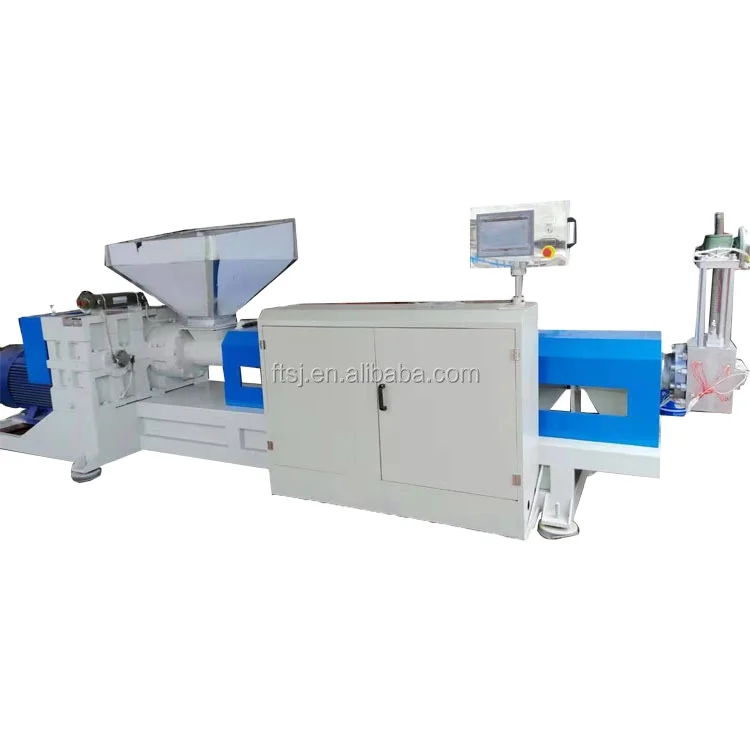

ПЭТ переработанная пластиковая грануляторная линия небольшой пластиковый гранулятор для пластиковых отходов экструзии

- Категория: >>>

- Поставщик: Hebei Fangtai Plastic Machinery Manufacture Co. Ltd.

Сохранить в закладки 1601267086545:

Описание и отзывы

Характеристики

Product display

Name | PP/PE Plastic recycling single stage water cooling pelletizer for recycle plastic |

Capacity | 100-120kg/h |

Screw | Single |

Heating | electronic heating |

Cabinet | PLC or Button |

Motor | inverter control the speed |

main extruder | put the raw material in the main granulator , then it wil be melted into heated solid, there is heating wire,And the wire is made of copper , One of the properties of copper is that conduct heat quickly, Unique cooling structure design, thermal resistance of small, fast heat conduction wire skin, made of high temperature prevention material, which is featured with safe, water proof and high temperature prevention. | ||||||

auxiliary extruder | the heated solid then enter into the the auxiliary granulator, strong hydraulic will push the solid into thin threads through the mesh, and thin threads will trickle down to the cooling tank through the discharging hole. | ||||||

cooling tank | Mainly used to cooling the hot threads from the discharging hole of the auxiliary granulator. | ||||||

cutting machine | cut the strings into granules. granules are nice of averaged size. | ||||||

pick up contanier | catch the granules. | ||||||

control cabinet | control the temperature of the granules machine. | ||||||

Recommend Products

Company Profile

Hebei Fangtai plastic machinery manufacture Co.Ltd

Was founded in 2004,which is professional for waste plastic processing machinery.we are located in Baoding City,Hebei Province, and enjoying convenient transportation access.we are focused on researching and developing new products to meet markets and customers’ satisfaction.With abundant strength,we have lots of professional technicists and skilled workers.

Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction.We strictly carry on Product quality standard to produce and test.we are fully committed to producing technologically advanced kinds of PET bottles/pp pe/Garbage crushing washing drying recycling line;multifunctional plastic recycling line;

All kinds of crushers,washers,granulators,dryers,label removers,baler,bale breaker and other plastic recycling machines.Our products sell well both in domestic and international markets,before we exported to Czech Republic,America,Russia,Japan,Montenegro,Lebanon,Chile,Mexico,Algeria,Ethiopia,Nigeria,egypt,Turkmenistan,Uzbekistan,Tunisia,Bangladesh,India,SriLanka,Malaysia,Indonesia,Yemen,Thailand,cambodia,Pakistan,Jordan,Libya and other countries;

We will continuously introduce international advanced technology to produce better product lines.With sound business credit, guaranteed after-sales service, and modern manufacturing facilities, we have earned an reputation among our customers across the globe.Fully automated production facilities utilize the best in material, technology and humanresources, all of which are geared to provide complete customer satisfaction.

We welcome you to contact us and look forward to working with you!

Fangtai plastic machinery keeps high pace with the times,pioneers and innovates,We sincerely welcome traders both from home and abroad to discuss business with us! We are looking forward to join hands with you to achieve common progress and create a brilliant future!

Our Advantages

1) Good quality control

2) Highly competitive prices

3) Better product technology

4) Smooth communication

5) Effective OEM and ODM services

Contact us now for free project solution designing.

2) Highly competitive prices

3) Better product technology

4) Smooth communication

5) Effective OEM and ODM services

Contact us now for free project solution designing.

Customer Photos

Certifications

Product packaging

FAQ

1. How is the quality of your products?

Our products are manufactured strictly according to national and international standard, and we take a test on every machine before delivery.Our service-line is offered 24 hours with a quick respond: respond within 12 hours for domestic customer, 20 hours for international customer.

2.What guarantee do you provide?

If the quality is not consistent with the description as we said or promised before you place order, we promise you 100% refund.

3.How about price?

We have our own factory and can give you the lowest price, besides, we have a policy that " for saving time and absolutelyhonest business attitude, we quote as low as possible, discount can be given according to quantity".

Our products are manufactured strictly according to national and international standard, and we take a test on every machine before delivery.Our service-line is offered 24 hours with a quick respond: respond within 12 hours for domestic customer, 20 hours for international customer.

2.What guarantee do you provide?

If the quality is not consistent with the description as we said or promised before you place order, we promise you 100% refund.

3.How about price?

We have our own factory and can give you the lowest price, besides, we have a policy that " for saving time and absolutelyhonest business attitude, we quote as low as possible, discount can be given according to quantity".

Похожие товары

Высокоэффективные простые автоматизированные пластиковые грануляторы

Биоразлагаемый экструдер для пластиковых частиц PP/PE линия для гранулирования

Пластиковый гранулятор

3 837 694,00 ₽ - 4 385 936,00 ₽

Китай Высокое качество пластиковая нить/резьба гранулятор

219 296,80 ₽

Большая химическая машина для производства пластиковых частиц пластиковые грануляторы

Машина для производства пластиковых грануляторов

3 837 694,00 ₽ - 4 385 936,00 ₽

Новая древесно-пластиковая грануляторная машина для переработки отходов

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $