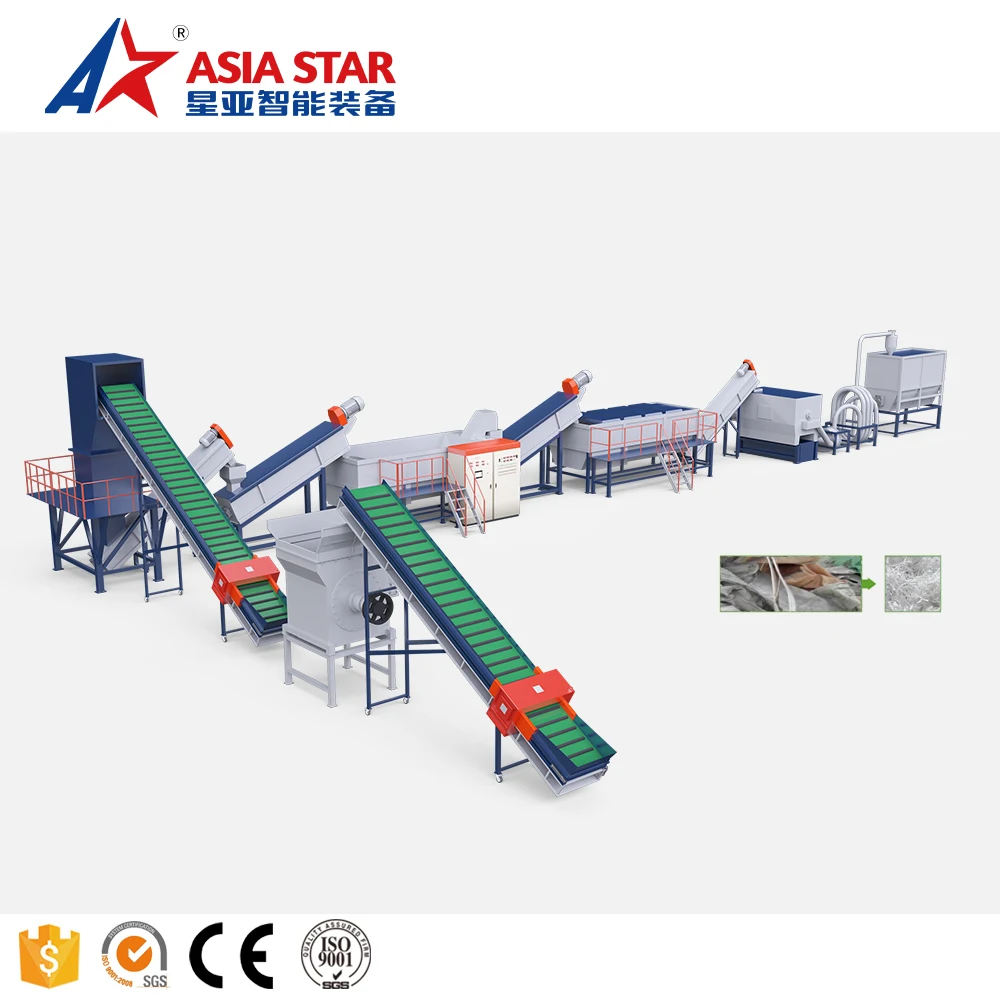

Пластиковая линия по переработке полипропиленовой пленки сделано в Китае

- Категория: >>>

- Поставщик: Xingya (suzhou) Intelligent Equipment Manufacturing Co. Ltd.

Сохранить в закладки 1601267276538:

Описание и отзывы

Характеристики

Products Description

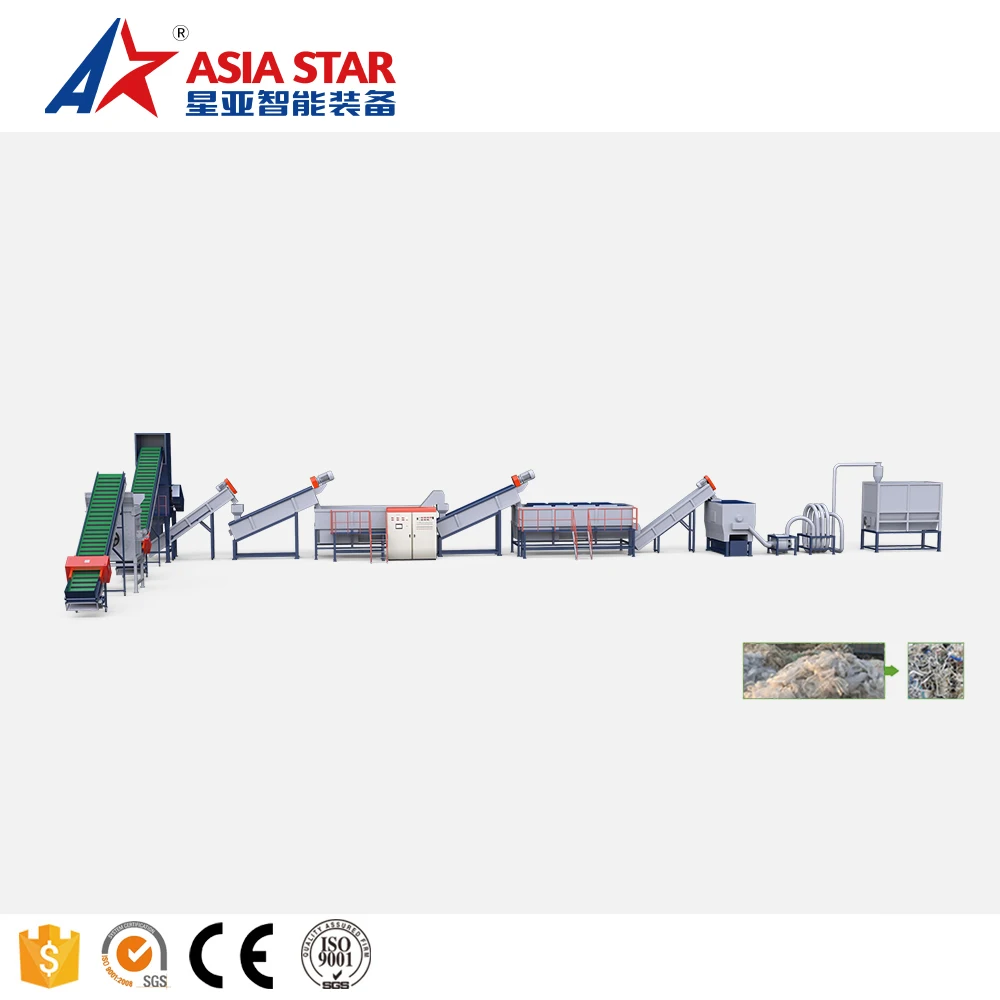

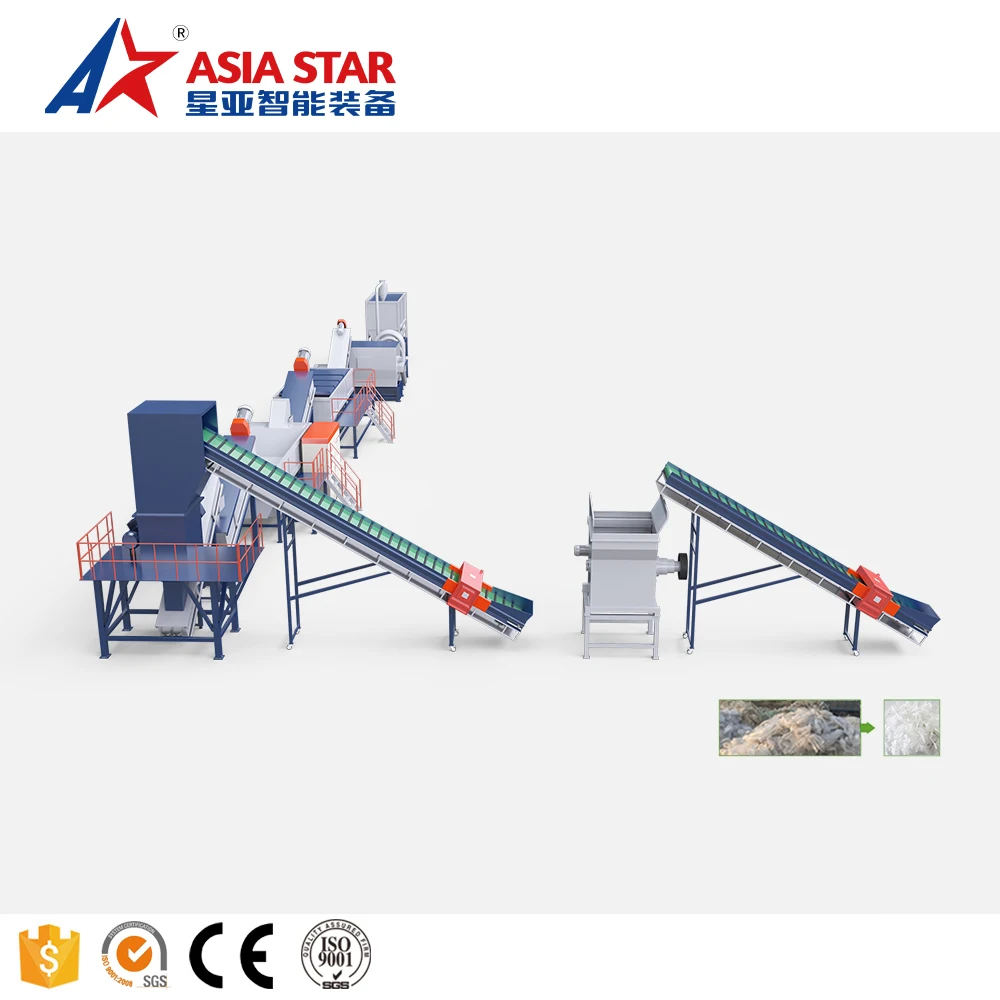

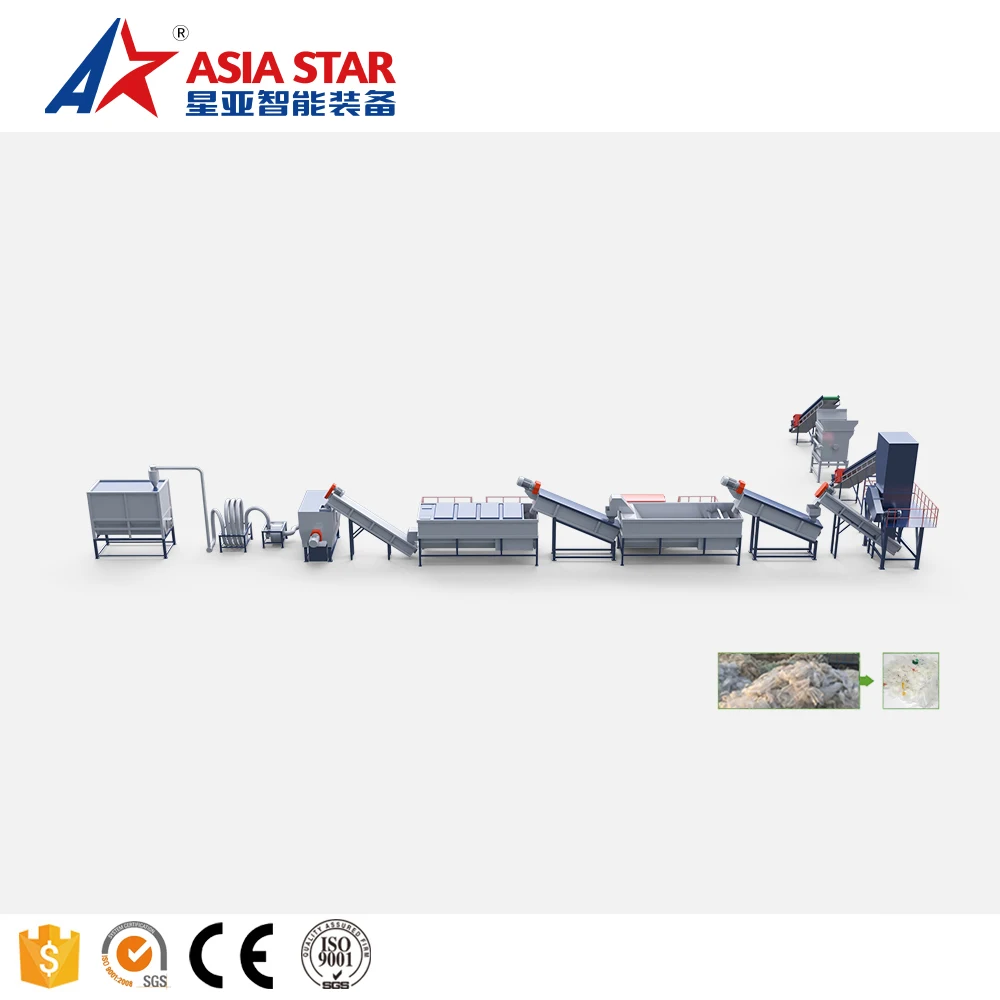

Plastic Recycling Machine

By means of introducing latest design from Europe and absorbing customer' s valuable advice,our technical design & manufacture level has been improved a lot!Nowadays,over 200 recycling lines have been already exported to 60 countries and regions in Latin- America,Europe,Mid- East and Africa.According to require- ment,design proposal is very flexible and customer-oriented.

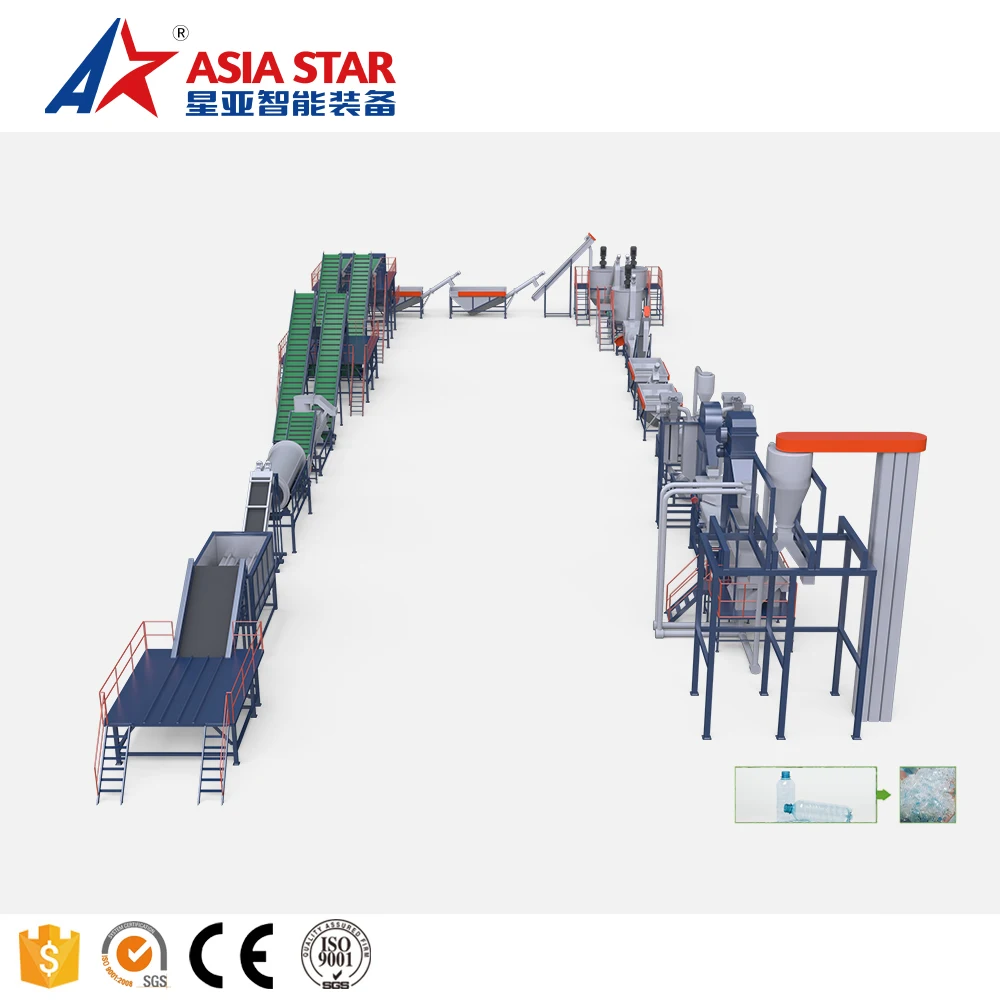

This PET bottle washing line is specially design to deal with PET bottles, such mineral water bottle, beverage bottles... the main function of this PET bottle recycling line usually include below points.

(1) First to crush and wash the PET flakes finally get clean flakes.

(2) Second to remove the labels thoroughly, third to remove the bottles caps fourth to dry the PET flakes, finally to get clean, pure and dry PET flakes. Combining wet crusher, friction washer, high speed friction washer floating washer and hot washer to guarantee the finally flakes good quality.

(3) And this production line is with high automatically operation and labor savings quality.

(4) With advanced design concept and constantly advises from customers, we can customized to meet all your specially demands.

(5) This PET bottle crushing washing recycling line could be installed "I", "L", and "U" shapes according to your workshop. We also could help you to design how to install the machines in your factory.

(1) First to crush and wash the PET flakes finally get clean flakes.

(2) Second to remove the labels thoroughly, third to remove the bottles caps fourth to dry the PET flakes, finally to get clean, pure and dry PET flakes. Combining wet crusher, friction washer, high speed friction washer floating washer and hot washer to guarantee the finally flakes good quality.

(3) And this production line is with high automatically operation and labor savings quality.

(4) With advanced design concept and constantly advises from customers, we can customized to meet all your specially demands.

(5) This PET bottle crushing washing recycling line could be installed "I", "L", and "U" shapes according to your workshop. We also could help you to design how to install the machines in your factory.

Basically the standard process for PET bottle recycling line design as below:

De-baling(bale opener)------ Label Scrapping(lable remover)-------- Persorting------Bottle Pre-washing ------ Manual Sorting and Metal Detecting-----Wet Grinding(crusher)-------Gravity Separation(floating washer)-------Chemical Washing for PET Flakes(Hot washer)-------High speed friction washer ------- Floating washing tank ------- Rinsing(clean water spraying)--------Drying--------Packing/storage hopper

De-baling(bale opener)------ Label Scrapping(lable remover)-------- Persorting------Bottle Pre-washing ------ Manual Sorting and Metal Detecting-----Wet Grinding(crusher)-------Gravity Separation(floating washer)-------Chemical Washing for PET Flakes(Hot washer)-------High speed friction washer ------- Floating washing tank ------- Rinsing(clean water spraying)--------Drying--------Packing/storage hopper

Main features for PET washing machine:

Trommel | Function: Efficient trommel ensures separation of materials from other debris: removal of stones, wood chips, small metals. |

Label remover | Function: The label remover machine is mainly used to peel the label paper on the PET bottle surface, especially the PVC or PS label applied on the PET bottle.Through the cooperation of the rotary and the fixed knives, the labels on the bottle body are peeled together, and the difference between wind force and gravity is used to completely separate the bottle body and the label, to preserve the integrity of the bottle and the bottleneck, and reduce the loss of high-quality bottle material. |

Crusher | Function: The crushing system adopts wear-resistant design to ensure that the system runs continuously for artyui long time. |

Floating washing tank | Function: The floating washing tank is designed for strong pressure underwater cleaning to remove residual impurities |

Steam washer | Function: Steam washer effectively removes sticky glue, oil stains and some small impurities on the surface of bottle flakes, which is critical to the life of downstream product filter components and product quality. |

High-speed friction washer | Function: The high-speed firction washer applies the corresponding blade striking force to different materials at a suitable rotation speed to achieve the desired cleaning effect. |

De-watering machine | Function: Can be equipped with the corresponding centrifugal dewatering machine and hot air drying system according to the water content set by the production requirements. |

Feature for PET washing line:

1. High automation level, try best to reduce your cost on labor (especially for three shifts) and ensure high processing capacity: 150-2000kg/hr

2. Friendly control system (PLC integrated & separated control on each machine) and Touch screen panel, easy for operation, monitor and emergency stop.

3. All parts contacting with plastic material and water are made of high-quality 304 or 316 stainless steel; Ensure no second pollution to flakes.

4. Ideal impurity removal effect. Here is from our customer's feedback.

1. High automation level, try best to reduce your cost on labor (especially for three shifts) and ensure high processing capacity: 150-2000kg/hr

2. Friendly control system (PLC integrated & separated control on each machine) and Touch screen panel, easy for operation, monitor and emergency stop.

3. All parts contacting with plastic material and water are made of high-quality 304 or 316 stainless steel; Ensure no second pollution to flakes.

4. Ideal impurity removal effect. Here is from our customer's feedback.

Company Profile

A-Star(Suzhou) Intelligent Equipment Manufacturing Co.,Ltd.

A-Star(Suzhou) Intelligent Equipment Manufacturing Co.,Ltd. is a modern factory, which engaged in the plastic extrusion machine and recycling machines' researching, manufacturing and saling. Our professional research teams, sales teams, rich experience and processing equipment will offer customers high quality machines and perfect after sales services.

Our major products including: single screw extruder, twin screw extruder, HDPE pipe production line, PP-R pipe production line, PVC pipe production line, plastic profile production line, plastic sheet production line, plastic mixing machine, waste plastic recycling machines, plastic pelletizing machines and relative auxiliary machines for the plastic machines. We will offer the customers the whole set of solution from extrusion to recycling and turn key projects. Our machines are highly praised by our customers for perfect perfomance, quick service, advantagetechnology.

Customer's satisfied is our target forever. We will offer detail solutions according to different customers detail conditions. Customers' expected products, services is what we are always insisting. High quality, Quick services, mutually beneficial will our promise to customers around the world.

Our major products including: single screw extruder, twin screw extruder, HDPE pipe production line, PP-R pipe production line, PVC pipe production line, plastic profile production line, plastic sheet production line, plastic mixing machine, waste plastic recycling machines, plastic pelletizing machines and relative auxiliary machines for the plastic machines. We will offer the customers the whole set of solution from extrusion to recycling and turn key projects. Our machines are highly praised by our customers for perfect perfomance, quick service, advantagetechnology.

Customer's satisfied is our target forever. We will offer detail solutions according to different customers detail conditions. Customers' expected products, services is what we are always insisting. High quality, Quick services, mutually beneficial will our promise to customers around the world.

Certifications

Product packaging

Main Products

FAQ

• Pre-sale: we give our client the detailed technician offer, sign the sales contract etc.

• In-sales: we supply the details layout, installation instruction, and technician support for the clients.

• After sales: we arrange engineer to install the machine and train the workers for our client.

• We have 24 hours service line to solve the after sales problem.

• We have free spare parts with the machine.

• We supply long term spare parts for every customer.

• We always update the new technology to every customer.

In order to match your requirement and provide you a proper quotation, please advice:

• What material do you want to recycling? PET bottle? PE film? PP woven bag? PE/PP bottle? or others?

• What capacity(kg/h) do you want?

• What is the final size(mm) of flakes you want?

• Other special requirements about the plastic pet recycling washing line you want.

• In-sales: we supply the details layout, installation instruction, and technician support for the clients.

• After sales: we arrange engineer to install the machine and train the workers for our client.

• We have 24 hours service line to solve the after sales problem.

• We have free spare parts with the machine.

• We supply long term spare parts for every customer.

• We always update the new technology to every customer.

In order to match your requirement and provide you a proper quotation, please advice:

• What material do you want to recycling? PET bottle? PE film? PP woven bag? PE/PP bottle? or others?

• What capacity(kg/h) do you want?

• What is the final size(mm) of flakes you want?

• Other special requirements about the plastic pet recycling washing line you want.

Похожие товары

3000 кг/ч Емкость ПЭТ бутылка дробления стиральная линия для переработки/пластиковые бутылки для отходов

45 000,00 $ - 49 999,00 $

Китай поставщика ПЭТ промышленности для продажи гранулятор EPS пены борту машины гранулы

1000кг /ч линия для рециркуляции ПЭТ бутылок

Дробилка для бутылок

100 000,00 $ - 200 000,00 $

Конкурсная цена, машина для переработки хлопьев

49 000,00 $ - 50 000,00 $

отходов полиэтиленовый мешок обезвоживания ldpe сельскохозяйственная пленка стиральная линия для пластиковой рециркуляции

Отличное качество Дробильная стиральная сушильная отходов пластиковые рециркуляции машины в обезвоживания машины

Новые поступления

Новинки товаров от производителей по оптовым ценам

Профессиональный пневматический гравировальный молоток

22,73-45,45 $

Специальные продажи экстремальное бездорожье Unimog Merce-des-Benz U530

6 000 $

Запасные части для мотоциклов сила 1 импульсная

Беспроводной велосипедный Спидометр Одометр ЖК-Смарт-подсветка

6,40-6,80 $

Вакуумный выключатель против сифон обратный клапан с

Оптовая продажа мужские футболки оверсайз с графическим рисунком 100% футболка премиум-класса хлопковая Футболка логотипом принтом на заказ без рисунка

4,85-7,10 $

2025 новый солнцезащитный крем SPF50 ++ водонепроницаемый Стойкий УФ Отбеливающее масло контроль OEM Private Label

Оптовая продажа натуральное исцеление хрустальные черепахи ручной работы смешанный материал черепаха для украшения дома подарок

3,50-4 $