Индивидуальные 330 мл пластиковая бутылка сока наполнения и упаковки производственной линии

- Категория: >>>

- Поставщик: Zhangjiagang Honor Machine Co. Ltd.

Сохранить в закладки 1601270230574:

Описание и отзывы

Характеристики

Product Description

RCGF series water filling machine-Washing filling capping 3-in-1

This series of equipment is used for hot filling production of tea drinks, fruit juice drinks and other products. This series is a combination of sterilization, filling and sealing. the design is scientific and reasonable, so operate is simple. It is the preferred equipment for hot-filling drinks.The filling temperature of this machine is 55-95℃ hot filling, It adopts suspension air conveyor. When change the bottle,It only needs to adjust the conveying width, which is more efficient and labor-saving. Filling action is smooth, fast, high precision, reliable sealing, low material loss and other functions, avoid secondary pollution of materials effectively .

It adopts advanced technologies such as human-machine interface touch control system, PLC computer control, frequency converter control, etc. It has high degree of automation and easy operation.

Different filling capacities

14-12-5 Bottle Water Filling Line Capacity:1000-3000 bottles per hour.

18-18-6 Bottle Water Filling Line Capacity:3000-5000 bottles per hour.

24-24-8 Bottle Water Filling Line Capacity:6000-9000 bottles per hour.

32-32-10 Bottle Water Filling Line Capacity:9000-13000 bottles per hour.

40-40-12 Bottle Water Filling Line Capacity:14000-18000 bottles per hour.

14-12-5 Bottle Water Filling Line Capacity:1000-3000 bottles per hour.

18-18-6 Bottle Water Filling Line Capacity:3000-5000 bottles per hour.

24-24-8 Bottle Water Filling Line Capacity:6000-9000 bottles per hour.

32-32-10 Bottle Water Filling Line Capacity:9000-13000 bottles per hour.

40-40-12 Bottle Water Filling Line Capacity:14000-18000 bottles per hour.

Specification

Model | RCGF14-14-5 | CGF14-12-5 | RCGF18-18-6 | RCGF24-24-8 | RCGF32-32-10 | RCGF40-40-10 | |||||

Capacity(500ml/bottle/h) | 1000-3000 | 2000-4000 | 3000-5000 | 6000-9000 | 9000-13000 | 14000-18000 | |||||

Suitable bottle shape | Round bottle or square bottle | ||||||||||

Filling precision | ≤+5mm(liquid level) | ||||||||||

Bottle height(mm) | 160-320 | ||||||||||

Filling pressure(Mpa) | 0.15-0.35 | ||||||||||

Filling temperature(℃) | 55-85 | ||||||||||

Total power(kw) | 4.4 | 4.5 | 4.8 | 5.5 | 8 | 9 | |||||

Overall dimensions(mm) | 2300*1800*2200 | 2400*1880*2000 | 2600*2000*2200 | 3050*2300*2300 | 3650*2800*2400 | 4000*3150*2500 | |||||

Weight(kg) | 3200 | 3050 | 4500 | 6500 | 7500 | 8600 | |||||

Details Images

1, Water Treatment System

Simple operation / Less maintenance / Lower power cosumption

Water treatment system refers to the measures taken to make the water quality meet certain use standards. The physical characteristics of water, such as temperature, color, transparency, odor and taste, are filtered or treated so that water can be used directly for drinking or other purposes.

2,Processing system

Complete juice processing system is not only can be suitable for common products ,but also can satisfy special requirements of customers ,for example concentrated juice, fresh juice, tea, coffee or flavor milk, cream or high viscosity products containing fiber and large pulp granules. it included high-shear emulsifying tank, plate heat exchanger, double filter, mixing tank, UHT sterilizer, homogenizer machine, buffer tank, hot water system, hot water tank and CIP cleaning system.

3,Washing Filling Capping 3-in-1 Machine

This machine is mainly used for hot filling production of tea drinks, fruit juice drinks and other products. This series is a combination of sterilization, filling and sealing. the design is scientific and reasonable, so operate is simple. It is the preferred equipment for hot-filling drinks.

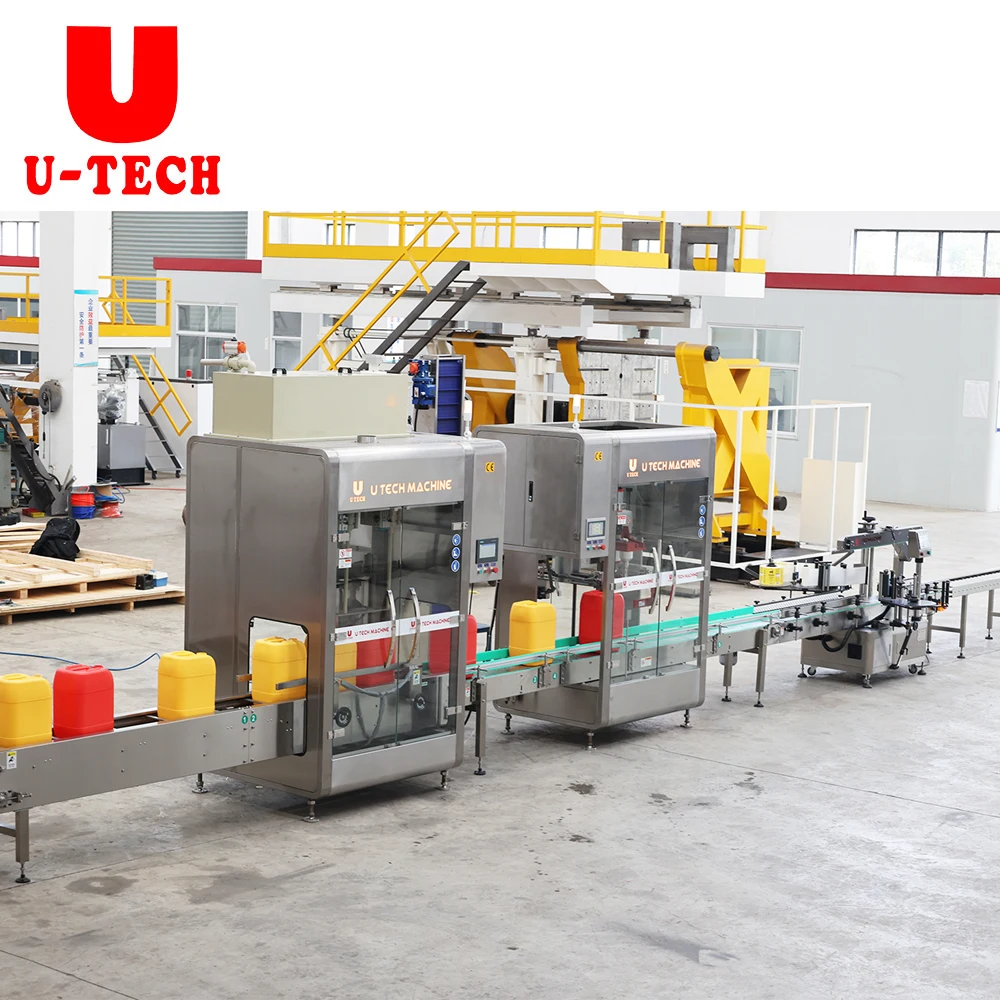

4,Labeling & Packing Machine

As customer request and market demand ,we provide the suitable solution for the final product package ,

We have various kinds of options .Labeling machine have the PVC sleeve label ,BOPP hot glue label,Adhesive stick label ,Wet glue label ,and packing machine have the film shrink machine and carton box package.

We have various kinds of options .Labeling machine have the PVC sleeve label ,BOPP hot glue label,Adhesive stick label ,Wet glue label ,and packing machine have the film shrink machine and carton box package.

5,Bottle Blowing Machine

1)Excellent Mechanical Strength, impact-resisting, and non-craking.

2)Bottle mouth and thread are of precise measurement.

3)Plastic Medicine Bottle's safe thread can be molding directly.

4)The size and weight of the product can calculate and design clearly and meet the requirement of the design without any deviation.

5)The surface of the bottle mouth, neck and the body is good luster and smoothness, the standard of bottle body is unity.

6)The joint seam on the bottle body is smooth, no scrap rubber.

2)Bottle mouth and thread are of precise measurement.

3)Plastic Medicine Bottle's safe thread can be molding directly.

4)The size and weight of the product can calculate and design clearly and meet the requirement of the design without any deviation.

5)The surface of the bottle mouth, neck and the body is good luster and smoothness, the standard of bottle body is unity.

6)The joint seam on the bottle body is smooth, no scrap rubber.

Turnkey Solution

We are not only a filling equipment manufacturer, but also design and build factories, equipment layout, circuit layout and equipment operation schemes. Our equipment is designed carefully, easy to use and easy to manage. Whether you need a machine or a complete filling and packaging system, we have rich experience to ensure the successful completion of your project.

Company Profile

Zhangjiagang Honor Machine CO.,LTD

Honor Machine provides the wide range of liquid filling capabilities and industry experience while delivering the lower cost of ownership for our customers.

We are committed to:

1) Automatic industry water treatment system(Reverse Osmosis, Ultrafiltration)

2) All kinds of beverage filling and packaging production lines (water, juice, carbonated drink, all kinds of liquors)

3) 3-10L beverages filling and packaging production line

4) 3-5 gallon beverages filling and packaging production line

5) Alcohol/beer filling and packaging production line

6) All kinds of Edible Oil and Oil Filling and Packaging Production Lines

7) All kinds of sauce filling and packaging production lines (honey, jam)

8) Zip-top can filling and packaging production line

9) Automatic/Semi automatic bottle blowing system

10) Automatic injection blowing/ Extrusion blowing machine

Your Success Is Our Mission!

We are committed to:

1) Automatic industry water treatment system(Reverse Osmosis, Ultrafiltration)

2) All kinds of beverage filling and packaging production lines (water, juice, carbonated drink, all kinds of liquors)

3) 3-10L beverages filling and packaging production line

4) 3-5 gallon beverages filling and packaging production line

5) Alcohol/beer filling and packaging production line

6) All kinds of Edible Oil and Oil Filling and Packaging Production Lines

7) All kinds of sauce filling and packaging production lines (honey, jam)

8) Zip-top can filling and packaging production line

9) Automatic/Semi automatic bottle blowing system

10) Automatic injection blowing/ Extrusion blowing machine

Your Success Is Our Mission!

Why Choose Us

FAQ

Q1.How to tell us your enquiry?

A1:You can contact us by email, phone call, Instant Messenger (Trademanager, WhatsApp, Skype) and let us know your requirement.

Q2:Are you a factory or trading company?

A2:We are a factory, professional water treatment system manufacturer and bottled water filling & packing machinery with about 7 years experience. Factory covers an area of 5,000 square. There have been more than 50 countries use our products.

Q3.Where is your factory?

A3:Our factory is located in NO.198 Zhenbei Road Leyu Town,Zhangjiagang City,JiangSu Province,China, it is near to Shanghai or Wuxi (airplame and train both available). If you arrive at Shanghai or Wuxi, we can pick you up to visit our factory.

Q4.How about after-sale service?

A4:After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.After the commissioning, we will package the equipment by standard export package for shipment.

Q5:How long is the warranty of your equipment and installation?

A5:2 years warranty after receipt check upon delivery.

We will send our professional engineers to your factory to install the machines and train your staff how to operate the machines. Customer pay air tickets go and back,accommodation and USD120 / day/person.

Q6:What is the features of our company?

A6: We provide turnkey project for customers, including sale and after-sale service; complete production line equipment supply; bottle design; layout programs provide; or provide auxiliary materials purchasing agent supplier information; equipment overseas installation and commissioning; operator training etc

Q7:How to guarantee your funds to be safe and delivery to be on time?

A7:Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

A1:You can contact us by email, phone call, Instant Messenger (Trademanager, WhatsApp, Skype) and let us know your requirement.

Q2:Are you a factory or trading company?

A2:We are a factory, professional water treatment system manufacturer and bottled water filling & packing machinery with about 7 years experience. Factory covers an area of 5,000 square. There have been more than 50 countries use our products.

Q3.Where is your factory?

A3:Our factory is located in NO.198 Zhenbei Road Leyu Town,Zhangjiagang City,JiangSu Province,China, it is near to Shanghai or Wuxi (airplame and train both available). If you arrive at Shanghai or Wuxi, we can pick you up to visit our factory.

Q4.How about after-sale service?

A4:After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.After the commissioning, we will package the equipment by standard export package for shipment.

Q5:How long is the warranty of your equipment and installation?

A5:2 years warranty after receipt check upon delivery.

We will send our professional engineers to your factory to install the machines and train your staff how to operate the machines. Customer pay air tickets go and back,accommodation and USD120 / day/person.

Q6:What is the features of our company?

A6: We provide turnkey project for customers, including sale and after-sale service; complete production line equipment supply; bottle design; layout programs provide; or provide auxiliary materials purchasing agent supplier information; equipment overseas installation and commissioning; operator training etc

Q7:How to guarantee your funds to be safe and delivery to be on time?

A7:Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

Похожие товары

Высокоскоростная Автоматическая асептическая машина для розлива кофе для производственной линии кофе

2 187 868,00 ₽ - 2 406 654,80 ₽

High efficiency 2 heads 5L liquid filling machine suitable for small business

360 998,22 ₽ - 382 876,90 ₽

Производственная линия наполнения автоматическая пластиковая бутылка для воды 3 в 1 производственная линия наполнения жидкости

3 281 802,00 ₽

Линия по производству газированных напитков в бутылках

Anti-corrosion 20 25 liters drum can filling capping machine Auto nozzle Preservatives filling weighing Line

984 540,60 ₽ - 1 640 901,00 ₽

Высокая эффективность профессиональный производитель фруктовых соков prdouction линия сок оборудование розлива/сок розлива

YB-J4B автоматические машины для розлива кокосового масла, разливочные машины для оливкового масла, пищевое масло, соусник, машина для наполнения укупорки

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $