60000 В четырехроликовый Электрический сепаратор для циркониевого песка титанового тантала ильменитовой руды

- Категория: >>>

- Поставщик: Ganzhou Gelin Mining Machinery Co. Ltd.Ganzhou Ltd.

Сохранить в закладки 1601345912845:

Описание и отзывы

Характеристики

60000v Four Rollers Electric Separator for Zircon Sand Titanium Iron Tantalum Ilmenite Ore

High tension (High voltage) electrostatic separator an dry separating equipment in the high voltage electric field, which eliminate the mineral according to the differences of materials electricity nature.The selection of the Non-ferrous metal and black metal, such as iron ore, zircon, gold, copper, rutile, primary limonite, beach placer, manganese ore tantalum, niobium, monazite, and primary retiles.The separation of impurity mineral which associated with feldspar and quartz.Decarburization of boiler powder and mine etc.

Features

1. With the reasonable structure, advanced technology, complete protection,safety and reliable, with better separating effect.

2. Easy to operate and maintain;

3. High degree of automation to achieve the feeding, heating, speed adjustment, high-pressure discharge, with high security.

4. Get high grade minerals.

| Model | GELIN-ES1 | GELIN-ES2 | GELIN-ES3 | GELIN-ES4 | GELIN2G-ES5 | GELIN2G-ES6 |

| Specificiation | 120×750×2, (120,220,165) ×1500×2 | (120,220,165) ×1500×4 | 320×1200 | 320×1500 | 320×1200/2 | 320×1500/2 |

| Operating Voltage | 0-55kv | |||||

| Motor Power (KW)-Heat | 4.5/13 | 4.5/13 | 12 | 15 | 15 | 18 |

| -Rotate | 2.2/1.5 | 2.2/1.5 | 2.2/2.2 | 3.0/3.0 | ||

| -Electro Discharge | 0.09 | 0.1 | 0.15 | 0.18 | ||

| Feeding Size(mm) | 0.1-2 | |||||

Capacity | 0.5-3 | 1-4 | 0.6-1.4 | 0.8-1.6 | 1-2 | 1.2-2.5 |

Dia.Of stationary electrode(mm) | 40 | 40 | 30 | |||

Dia.Of corona electrode(mm) | 0.3 | 0.3 | 0.4 | |||

| No.of electrode filament | 4 | 4 | 4 | 4 | 8 | 8 |

Maximum operating electrode distance(mm) | 85 | |||||

| Weight(t) | 0.6-1.9 | 2 | 0.7 | 0.8 | 1.8 | 2.2 |

| Overall Size(mm)appx | 2090×1020 ×2855 | 2090×1300 ×2855 | 1390×1980 ×1500 | 1390×2290 ×1650 | 1390×1980 ×2880 | 1390×2290 ×2880 |

1.Two Rollers Electrostatic Separator

2.Four Rollers High Tension Electrostatic Separator

Four rollers with chrome plated;

4 pieces gear motors; relay and protection;

| Model | GELIN-ES1 | GELIN-ES2 | GELIN-ES3 | GELIN-ES4 | GELIN-ES5 | GELIN-ES6 | GELIN-ES7 | GELIN-ES8 |

| Rollers QTY | 2pcs | 2pcs | 2pcs | 2pcs | 2pcs | 4pcs | 4pcs | 4pcs |

| Roller speed | 0-800r/min | 0-800r/min | 0-800r/min | 0-800r/min | 0-500r/min | 0-500r/min | 0-500r/min | 0-500r/min |

| Working voltage | 0-45kv | 0-45kv | 0-45kv | 0-45kv | 0-45kv | 0-60kv | 0-60kv | 0-60kv |

| Feed size | 0-2mm | 0-2mm | 0-2mm | 0-2mm | 0-2mm | 0-2mm | 0-2mm | 0-2mm |

| Capacity | 0.3-1t/h | 0.5-2t/h | 1-2.5t/h | 1-3t/h | 2-3t/h | 1-4t/h | 2-5t/h | 4-8t/h |

3.Arc Plate Electrostatic Separator

Feature

Auxiliary Equipment Bucket Elevator

Application&Successful Case

Ganzhou Gelin Mining Machinery Co., Ltd is an over 30 years professional manufacturer and exporter of mining machinery for crushing, screening, grinding, flotation, separation etc. in China. Gelin have a complete service system which can provide customer full service in mining field and after sales service.By now, Gelin’s equipments and services are exported to over 60 countries,include America, Russia, India, Africa, Brazil, Chile,South Africa,Zambia etc. Sincerely welcome customers to visit our factory.

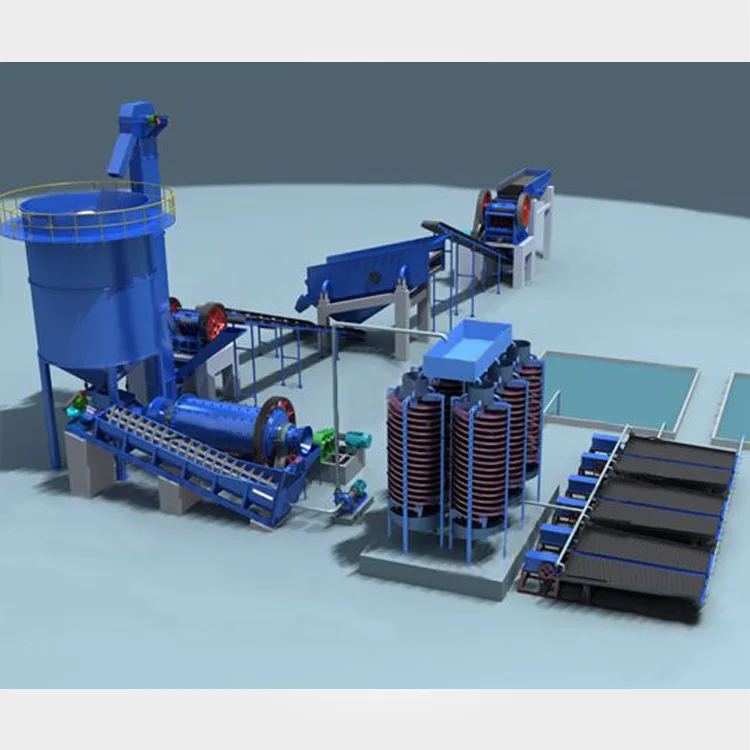

One Stop solution for beneficiation plant service

1.Starting by running the mineral beneficiation experiment. To provide our clients with the best solution accordingly;

2.Besides supply the flowchart design and equipment, we also provide the infrastructure design; Electrical and pipeline system design, etc. To help our clients complete the design of the whole plant;

3.After the installation, debugging of the equipment, the official production will also be guiding by our experienced engineers on site, to guarantee the output minerals perfectly meet your demands

1.Strict machine inspection before delivery;

2.Deliver the whole plant design for our clients which including infrastructure, electrical system and pipeline system design;

3.Trace the status of the shipping until the products received;

4.Prepare required documents to let clients pass custom clearance;

5.Dispatch experts to carry out below service on site:

1) Installation & debug of the machinery

2) Train the first-line operators & technical personnel

3) Carry out any other service clients may need

6. Provide technical exchanging & spare parts for life-long term

Q: How about your machine quality?

Q: If I don’t know installation and commissioning,what should I do?

Похожие товары

Высокоэффективный 100 т/ч 1500 мм Гравитационный спиральный парашют Хамфри для добычи хромитовой руды из золотого Титана и железа

Как использовать постоянный магнитный сепаратор высокой интенсивности для разделения титановой руды в черном илменитном песке

Высокоинтенсивный трехроликовый магнитный сепаратор 15000 г

Международный стандарт CE сертифицированное оборудование для разделения минералов монозит колумбит Олово Циркон сепаратор Электростатическая Машина

1000 Tpd хромированная медная руда для обработки золота установка элюирования

Высокоинтенсивный Перманентный редкоземельный валик гематит пирротит Лимонит магнетит полевой шпат магнитный сепаратор для обогащения

Оловянный Хромит колтан ильменит монацит Вольфрамит железная песчаная руда трехдисковый магнитный сепаратор цена

Новые поступления

Новинки товаров от производителей по оптовым ценам