Горячая распродажа! Стандарт CE линия по производству экструдирующего полистирола XPS двухшнековый экструдер xps

- Категория: >>>

- Поставщик: Shanghai Hansu Plastic Machinery Co. Ltd.

Сохранить в закладки 60481495986:

Описание и отзывы

Характеристики

Specialized in XPS

Introduction of XPS foam board production line

1.Focus on the manufacturing and technology research of complete sets of XPS foamed extrusion line

2.In China we master most advanced CO2 foaming technology for XPS extrusion line, can provide turn-key project solution for domestic and overseas customers.

3.Full automatic control of processing, with stable and efficient productions

Model disctription:

(S - means the 1st stage is single screw extruder, D - means the 1st stage is double screw extruder)

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

Notes: (1st stage screw Recommend to use double-screw)

Equipment list

Required equipment:

1.Material loading and feeding system (Germany brabenda for option)

2.1st stage of parallel double screw extruder

3.Foam agent injection system (Linde or Lewa for option )

Foaming agent : HCFC, R22,R 152a, DMC, Butane Ethanol,CO2.

4.Screen exchanger

5.2nd stage of single screw extruder

6.Static mixer

7.Die

8.Calibration unit

9.Haul-off unit

10.Cooling conveying roller

11.Edge cutter

12.Main Cross cutter

13.Electric control system ( ABB, SIEMENS, SCHNEIDER Brand)

Optional list

1.Surface planer and groover

2.Longitudinal groover (longitudinal trimming and shiplap, like SL,TG,RC)

3.Cross groover (cross trimming and shiplap)

4.Cooling and turning rack (vertical cooling tower )

5.Packaging machine

6.Automatic packing machine

7.Recyling machine

Related photo of Complete production line for XPS foamed board .

1. Material loading and feeding system

Material loading: Vacuum absorption

Material feeding: Weight-loss type or weight-adding type

Feeding platform: Standard or scutomized.

Feature: Ensure precise and stable feeding.

2. Foaming agent injection system .

Advanced CO2 foaming technology system, Linde, LEWA or domestic for option

For ethonal or HCFC, or DME, Plunger or diaphragm pump, combined with the flow meter to form a closed loop control system, with good stability of Injection.

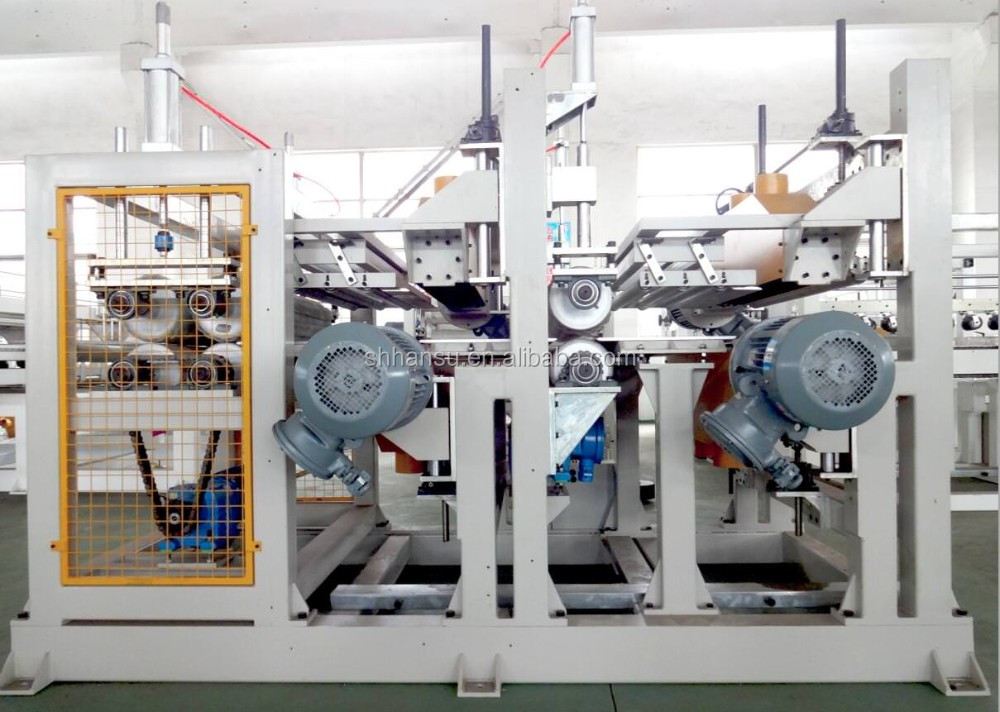

3. Extrusion system.

1st stage adopts parallel double-screw for bigger capacity and more stable extrusion

2nd stage adopts single-screw extruder

with specially designed cooling system

4. Slot Die system

Core technology for effective forming of the product .

The following equipment regarded as the downstream equipment of the XPS line.

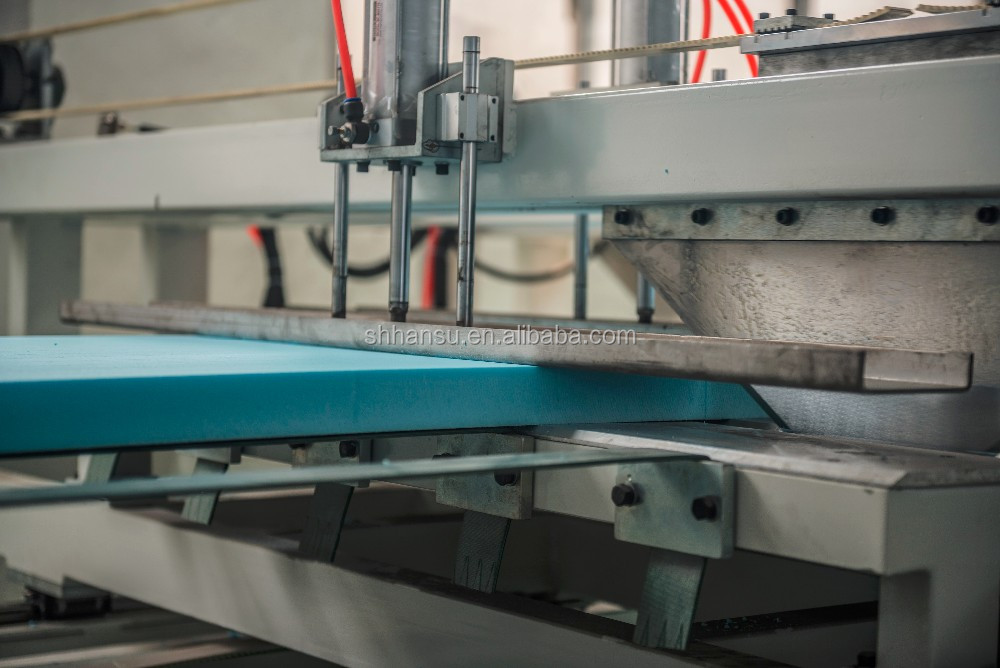

Calibration and Haul-off unit.

Cooling conveyor roller .

Embossing Roller unit .

Required to print the logo or special printing.

Edge cutter

.

Surface planer and groover

For producing XPS board with rough surface (removing skin),and with groove. Groove size can be adjusted.

Main cross cutter

Length-side trimming unit

For length-side trimming and shiplap (SL,TG,RC)

End-side trimming unit

For end-side trimming and shiplap (SL,TG,RC)

Vertical cooling and turning frame

Designed for the limited factory size for save the space.

Electric control system

Easy-operation, with ABB, SIEMENS and Schneider elements.

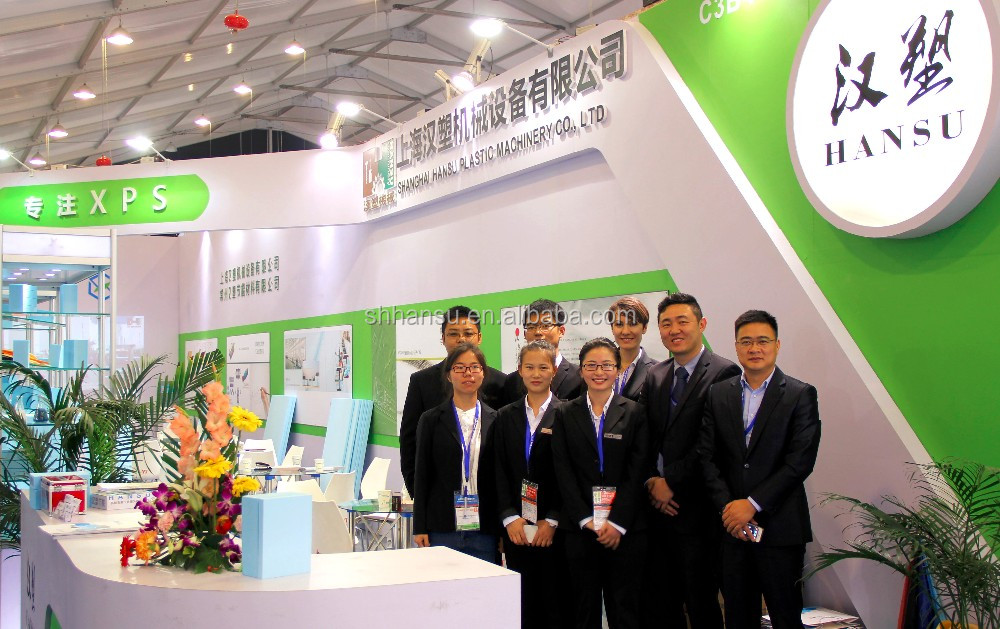

Only focus on XPS .

Since the establishment of Hansu company, we only focus on the develop and improvement of XPS foaming tehcnology and machinery.

Care about every Detail

Good quality depends on every details of the machine. And Good quality machine and technology can guarantee the XPS PRODUCT QUALITY.

Show the running line during your visit

Our brother company-HANSU energy saving company, Can show you our running line at any time during your visit. It can help you know more about working condition of our line.

Technical team for service

We have a professional team of engineers, can provide you the technolgoy support and after-sale service as you required.

1.Our company focused on the foaming technology of XPS production line since 2007. And the first XPS production line with CO2 foaming was successfully developed in 2009 and exported to Turkey. This production line is still well operated.

2. Since 2012, our company (HANSU MACHINERY) been the highly recommended supplier of the international HCFC phaseout program of UN Montreal protocol.

3. Since our company established, we have supplied more than 20 units of XPS production line with CO2 foaming to domestic and overseas market and supplied the whole technical support for our customers. We have gathered a rich experience of the technical processing of the CO2 foaming production line.

4. In order to provide more improvement of the equipment and show our production line and offer comprehensive solutions for the users, the brother company of HANSU MACHINERY, HANSU ENERGY SAVING company for XPS product is established at the beginning of 2016.

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

Похожие товары

Высокочастотный ферритовый трансформатор серии EE EE13

ПЭТ параллельный двойной винтовой экструдер цена пластиковая машина

Система резания в воде, наполнители caco3, машина для горячего плавления маточного экструдера

Calcium carbonate filler masterbatch extruder machine with kneader

Электрический магнитный портативный генератор переменного тока с постоянным магнитом, 2 кВт, генератор свободной энергии, прайс-лист для продажи, Корея, генератор

Высококачественный пластиковый экструдер с двойным винтом SJSZ45/90, цена производителя Beierman по хорошей цене

Термоплавкий экструдер/двойной экструдер/экструдер для макаронных изделий на продажу

Новые поступления

Новинки товаров от производителей по оптовым ценам