D серии горизонтальный центробежный чугун многоступенчатый насос

- Категория: >>>

- Поставщик: Shijiazhuang Naipu Pump Co. Ltd.

Сохранить в закладки 60533089553:

Описание и отзывы

Характеристики

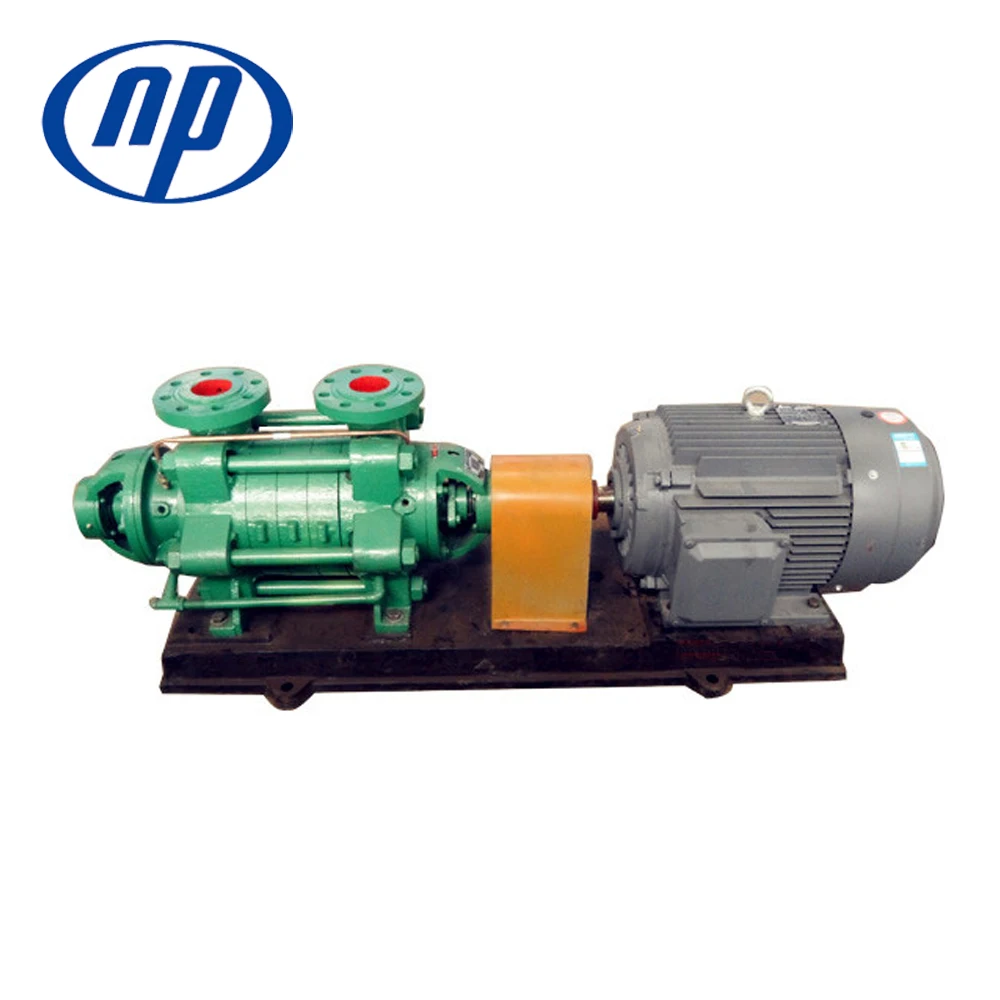

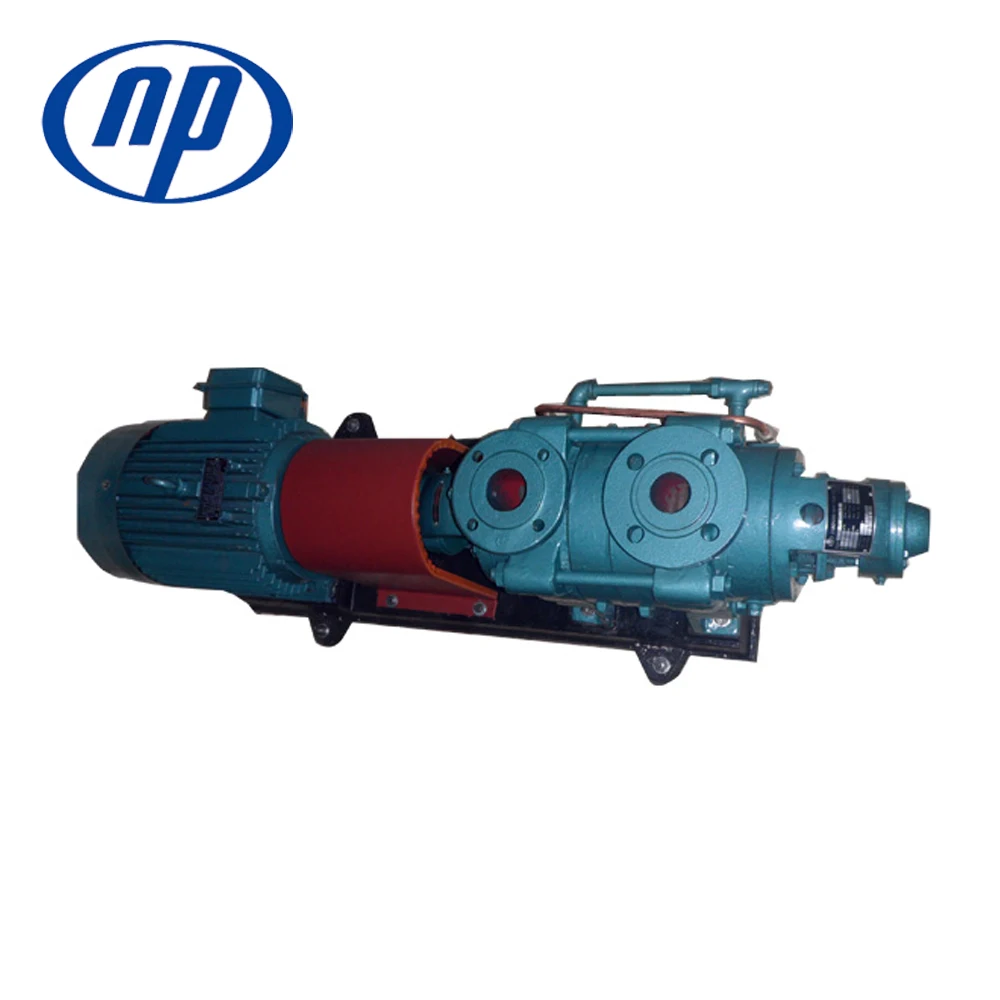

D series Horizontal Centrifugal Cast Iron Multistage Pump

Description of D multistage pump

D/DG pump is a horizontal multistage centrifugal pump, which is fit for transportation clean (impurity content is less than 1%, granularity is less than 0.1mm) and or other liquid with physical and chemical characters like clean water.

D pump transportation medium temperature is not more than 80°C, which is fit for mine discharge and water feeding to factory and city.

DG pump transportation medium temperature should not be more than 105°C, which is fit for water feeding to small boiler or similar applications.

Multistage Water Pump Product features

| High efficiency, convenient to instal and maintain | Adopts high efficiency and energy saving water power model. This series pump be of high efficiency, wide performance scope, operation placidly, low noise, long working flife and convenient to assemble and maintain etc. |

| Shaft seal | Adopts soft padding seal or mechanical seal, it is safe and reliable, stuctures is simple and it is convenient to maintain |

| Longer time to use | The shaft is whole sealing structure, that made if not contact with medium, it won't be rusted, so the using life is longer. |

Water pump operating conditions

• Medium temperature: <+105℃

• Capacity range: 3.75-500 m3/hr

• Head range: 49-680 m

• Speed: 1480-2950 r/min

Notice: Y series motor can't be used in well. YB series motor can be used in well, but can't be used for excavation industry. If used for excavation industry, must use YBK series motor.

Pump Type and Definition

D(DG) 155-67X9

D multistage centrifugal pump

DG multistage boiler feed pump

155 flux (m3/h)

67 single stage lift (m)

9 stage

Pump performance parameters

Pump construction drawing

Main part number at the drawing

1. Shaft 4. Inlet part 5. Severed head packing ring 6. Shaft 7. Medium part 8. Guide vane 9. Outlet part 10. Balance plate | 11. Foot casing 12. Shaft sleeve 14. Balance disc 15. Balanced wrap 16. Guide vane 17. Impeller 18. Packing ring 19. Severed head impeller |

Pump selection chart

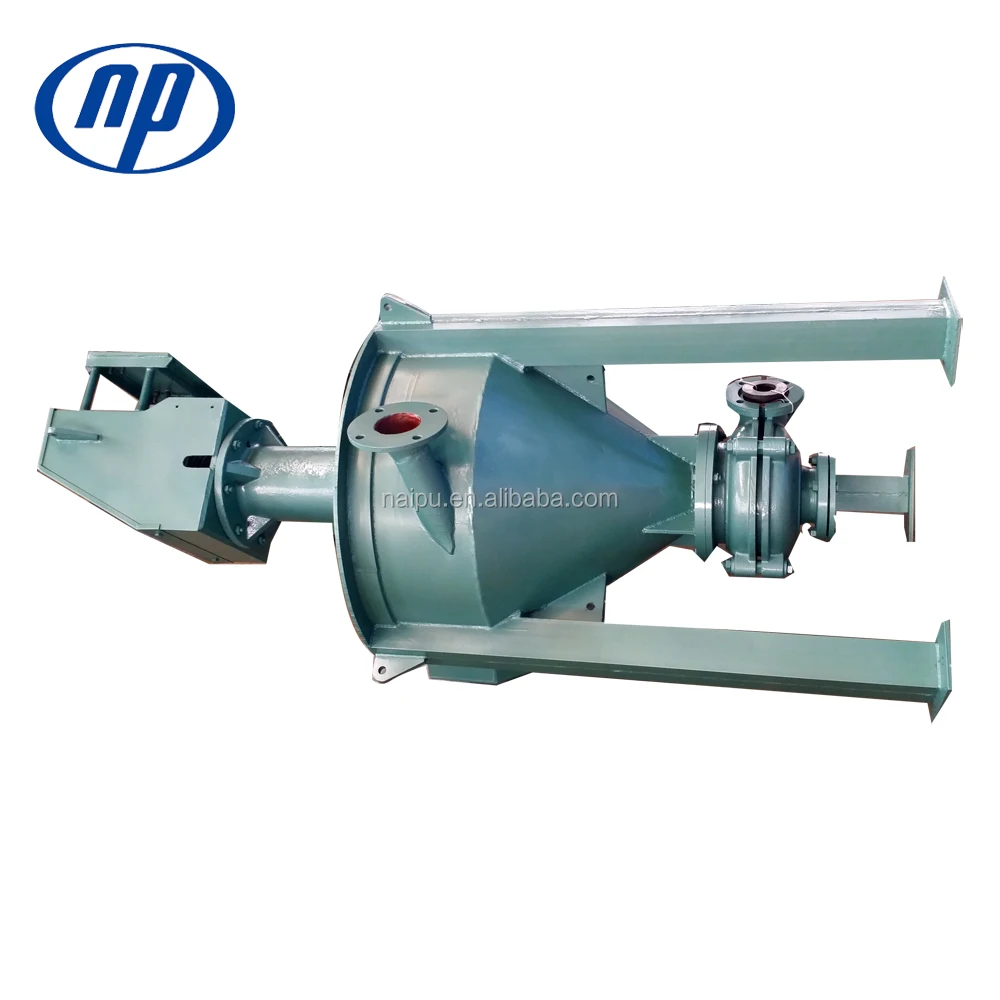

We can produce many kinds of centrifugal slurry pump for mining, sand and other solids slurry transporting.

|  |

|  |

CE, SGS, ISO9001 Certification

Packaging details

1. Outside package: standard export wooden cases.

2. Inner package: Stretch film.

What service of Shijiazhuang Naipu?

| OEM service | Produce the pump and spare parts according to client's drawing or sample. |

| Pump slection | Help customers select the type, size and operating speed of pumps that will perform at the lowest cost. |

| Using service | Offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. |

| Quality control | Pay more attention to the quality in every process with different instruments. |

| Material service | Interchangeable metal design allow best material choice for any application. |

| After-sales service | Provide lifetime after sale service to solve any question during uses and large stock for standard spare parts. |

| Guarantee | One year guarantee for whole machine except of the wet end parts. |

Shijiazhuang Naipu Pump Co., Ltd is a professional manufacturing enterprise of slurry pumps. We have about 30 years experiences and export to worldwide countries. Our technical team consists of talents specialized in hydraulic machinery, casting, heat treatment, engineering, material science and machining. We proudly manufacture quality pumps whose parts are 100% reverse interchangeable with major brands. This means no more inventory hassles when you decide to use another pump supplier.

Похожие товары

Горизонтальный шламовый насос промышленной обработки для транспортировки трубопроводов 200ZJ-70

10 дюймов Большой Золотой грунтовой насос

50ZJF резиновый выстроились бак Slurry Scum насос для целлюлозно-бумажной промышленности

6X4 EE - AHE сложный металлический лопастной насос для крахмала с резиновой прокладкой

100ZJF вертикальный центробежный шламовый насос для пены/Bomba de espuma

Центробежный насос мобильный четырехколесный тип прицепа большой поток затопления дренажный грузовик

Пропорциональный насос для подачи удобрений химической промышленности Аква-Дозирующий осевой-поршневой-переменный-насос

Новые поступления

Новинки товаров от производителей по оптовым ценам