M4 m6 m8 m10 wcu 70/30 медный вольфрамовый резьбовой нарезающий электрод для edm

- Категория: >>>

- Поставщик: Changsha Mingguan Metal Technology Co. Ltd.

Сохранить в закладки 60664770657:

Описание и отзывы

Характеристики

m4 m6 m8 m10 wcu 70/30 copper tungsten thread tapping electrode for edm

copper tungsten thread electrode is used when a product or part needs to have a high heat resistance, low thermal expansion and high electrical or thermal conductivity. tungsten copper rod supplier is used to make engines and electrical devices. It is also used in the fields of aviation and spaceflight. Electrodes, refractory parts, heat sinks, rocket parts and electrical contacts are all made out of tungsten copper alloy. The alloy is also made into sheet metal, tubing and plate metal. Tungsten copper alloy is used to make contacts for both high and low voltage electrical devices, and for high speed steel devices and switches.

CuW50 and CuW55 have the lowest Tungsten contents. They are both good switching and contact materials for oil filled devices. CuW55 is also used for arcing contacts in oil circuit breakers and arcing edges of selectors and switchblades in transformer tap changers.

CuW65 and CuW70 are used as contact materials in severe arcing applications including gas, oil and some air circuit breakers. They are also used for arcing edges on selectors and reversing switch blades.

CuW75 and CuW80 are used as contact materials under extreme arcing conditions. Applications include arcing contacts in gas and oil circuit breakers, contactors and transformer tap changers, arcing plates and arc runners in power switching equipment.

CuW85 and CuW90 have the highest Tungsten content. They are used as contact materials where resistance to contact welding, sticking and arc erosion are critical. They also provide satisfactory heat and current interruption capabilities. Typical applications are power vacuum switches and high power spark gap electrodes, etc

PLEASE BE NOTED THAT WE CAN PRODUCE THE TUNGSTEN COPPER ELECTRODE ACCORDING TO CUSTOMERS' DRAWING OR SAMPLES.

Pictures of our copper tungsten thread electrode

What's Tungsten Copper Alloy?

Tungsten copper alloy (Copper Tungsten Alloy, CuW, or WCu) is a pseudo-alloy of copper and tungsten. As copper and tungsten are not mutually soluble, the material is composed of distinct particles of one metal dispersed in a matrix of the other one. The alloy combines the properties of both metals, resulting in a material that is heat-resistant, ablation-resistant, high thermal and electrical conductivity, and easy to machine. Parts are made from the WCu alloy by pressing the tungsten particles into a desired shape, sintering the compacted part, then infiltrating with molten copper. Sheets, rods and bars of the alloy are available as well.

Tungsten copper parts provided by us are all with these properties. The electrical and thermal properties of the alloy vary with different proportions. Copper increases the thermal conductivity, which plays a huge part when being used in circuit breakers. Electrical resistivity with an increase in the percentage of tungsten present in the alloy, ranging from 3.16 at 55% tungsten to 6.1 when the alloy contains 90% tungsten. An increase in tungsten leads to an increase in ultimate tensile strength up until the alloy reaches 80% tungsten and 20% copper with an ultimate tensile strength of 663 MPa. After this mixture of copper and tungsten, the ultimate tensile strength then begins to decrease fairly rapidly.

Chemical Composition of our tungsten copper alloy

Class | Chemical Composition(Wt%) | Density | Hardness | Resistance rate | IACS | Bending strength | ||||

Cu | Total Additives≤ | W | g/cm3≥ | kgf/mm4≥ | um.cm≤ | %≥ | MPa≥ | |||

W93Cu07 | 7±1.0 | 0.5 | balance | 17.5 | 270 | 7.2 | 26 | 1190 | ||

W90Cu10 | 10±2.0 | 0.5 | balance | 16.75 | 260 | 6.5 | 27 | 1160 | ||

W85Cu15 | 15±2.0 | 0.5 | balance | 15.90 | 240 | 5.7 | 30 | 1080 | ||

W80Cu20 | 20±2.0 | 0.5 | balance | 15.15 | 220 | 5.0 | 34 | 980 | ||

W75Cu25 | 25±2.0 | 0.5 | balance | 14.50 | 195 | 4.5 | 38 | 885 | ||

W70Cu30 | 30±2.0 | 0.5 | balance | 13.80 | 175 | 4.1 | 42 | 790 | ||

W65Cu35 | 35±2.0 | 0.5 | balance | 13.30 | 155 | 3.9 | 44 | 650 | ||

W60Cu40 | 40±2.0 | 0.5 | balance | 12.75 | 140 | 3.7 | 47 | 600 | ||

W55Cu45 | 45±2.0 | 0.5 | balance | 12.30 | 125 | 3.5 | 49 | 565 | ||

W50Cu50 | 50±2.0 | 0.5 | balance | 11.85 | 115 | 3.2 | 54 | 534 | ||

Our copper tungsten alloy electrode

is suitable for EDM machining of those materials.

Advantages: low wear, high contour sharpness,good machinability.

Tungsten copper electrode is a good use of high-purity tungsten metal powder and high purity characteristics of the plasticity of copper powder.

Tungsten copper electrodes can be divided into EDM electrode, high-voltage electrode discharge tube and electronic packaging materials

Tungsten alloy bar

Specification:Thickness>1mm;Width<200mm;Length<300mm; Because of the high eletrical conductivity and low consumption, copper tungsten alloy bar are widely used to make Grid siderod, Lead, Support, Electrode for the Gas discharge lamp

Copper Tungsten Alloy Heat Sink

Copper tungsten alloy is widely used as heat sinks concerning with radiator for car, refrigeration and air conditioning systems, because of its low thermal expansion, heat-resistant, ablate-resistant, excellent thermal and electrical conductivity. WCu heat sinks galvanically plated with Ni or NiAu or electroless Ni plated Semi-finished products: up to 100x100mm with a thickness of 0.5 to 50mm.

Copper Tungsten Alloy Electrical Contacts

Electrical contacts are subjected to extreme mechanical and thermal stresses during operation. For fractions of a second, temperatures rise to several thousand degrees as a result of the arcing. Our copper tungsten alloy materials are used owing to their unique physical properties.

Q:What's your main products?

A:Tungsten /molybdenum /tungsten alloy products.

Q: Why should I choose your company for partner?

A: As you know, the raw material of low price makes your product more competitive in the market. That means it will make your sell much easier.

Q:Do you use first class tungsten /molybdenum powder?

A:We only use first class tungsten / molybdenum powder,no recycle.

Q Delivery tungsten alloy products can be shorter?

A: Usually we make sure all the order delivery with 30 days.Tungsten copper 15 days.

Q:Price can be cheaper?

A: We use first class tungsten powder,the cost is high.

Q:Tungsten /Molybdenum products MOQ?

A:Please email to enquire per different products.

Q:Tungsten /Molybdenum sample?

A:Sample available,within 7~14 days.

Похожие товары

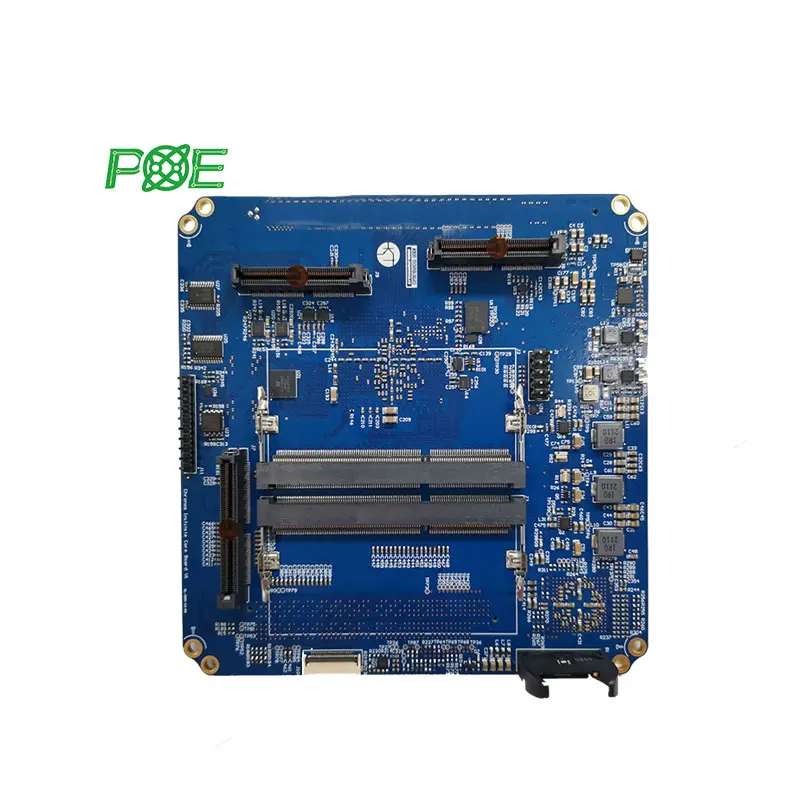

Изготовленная на заказ клавиатура PCB сборка от производителя Gerber File OEM Service

Экраном из нержавеющей стали винтовой сепаратор сепараторная машина для гранулирования классификации пульпы

FEP и PFA устойчивые к коррозии и износу гофрированные трубки

Производители высококачественных запасных частей для Грузовиков FOTON 1049/1046/1039, Задняя Ступица OE.NO 2205020320

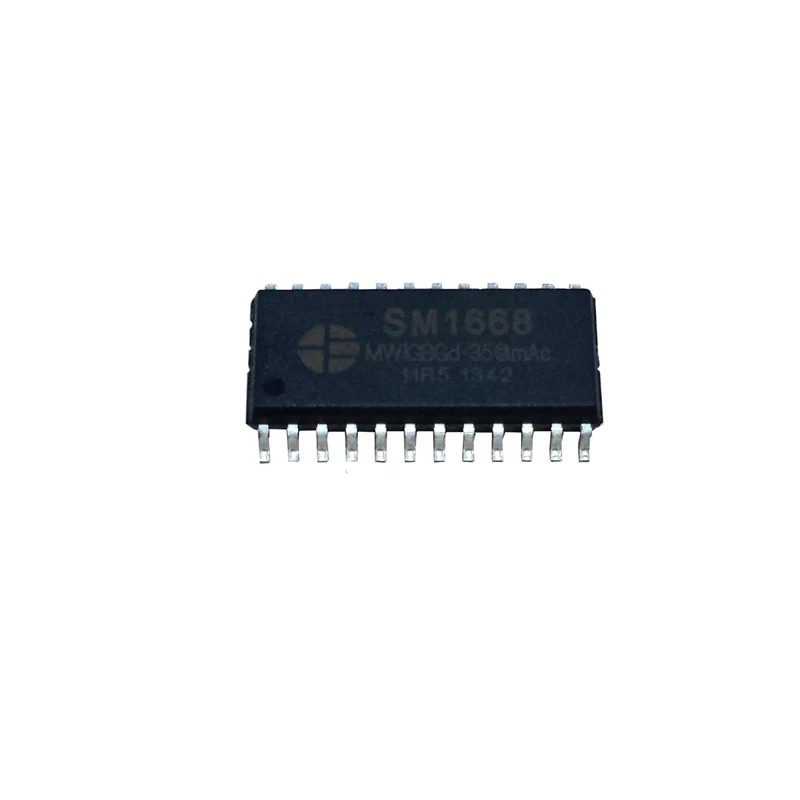

Индукционная плита SM1668 = SM1688 SM1668S SOP-24, панель дисплея IC, новый и оригинальный дисплей ic

Датчик расхода жидкости уровня мочевины для грузовиков 3690610 kx100

Китайский поставщик, хорошее качество, конвейерная транспортировка, автоматическая парковочная машина, роликовая цепь

Новые поступления

Новинки товаров от производителей по оптовым ценам