KINGS4500 C жидкий фотополимер Смола sla 3d принтер промышленная цифровая 3D машина для лазерной печати

- Категория: >>>

- Поставщик: Shenzhen Jinshi 3d Printing Technology Co. Ltd.

Сохранить в закладки 60701471271:

Описание и отзывы

Характеристики

| SLA | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

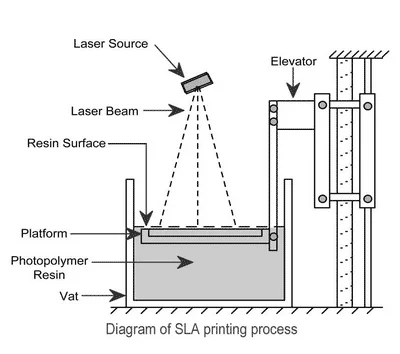

SLA process is the most studied,the most advanced and the most widely used method of rapid prototyping in the world ( also the rapid prototyping method adopted by our company). SLA technology is the principle of computer-controlled laser beam scanning on the surface of the photosensitive resin material point-by-point. The thin resin layer (about a few tenths of a millimeter) in the scanned area produces photopolymerization reaction, which solidifies to form a thin layer of the part. The table down a layer of thickness so that the surface of solidified resin is coated with a new layer of liquid resin. The next layer is scanned and repeated until the whole prototype is finished. Since the photopolymerization is based on light rather than heat, only the lower power of laser source?are needed at work. |  | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Comparison between SLA and FDM | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Introduction of equipment | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

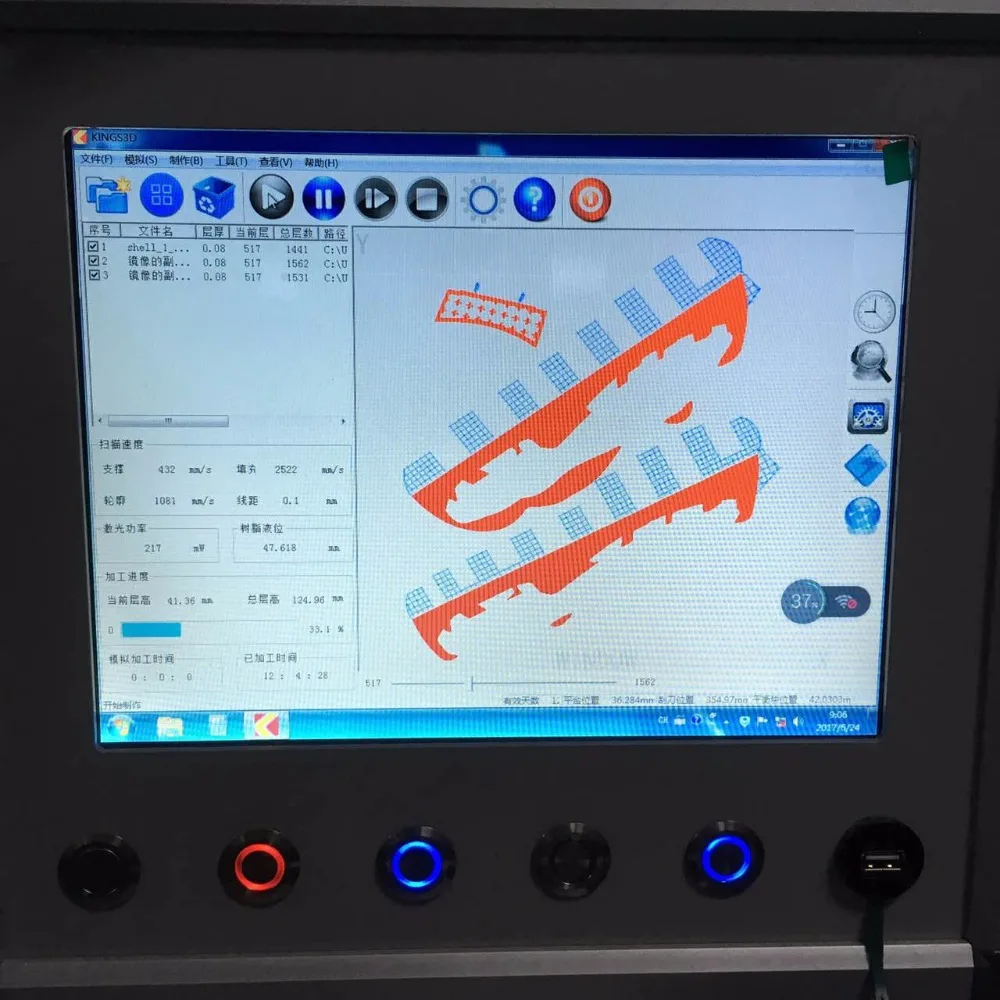

KINGS Control Software You can monitor the real-time through the display, the printing process. Print time, print speed.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

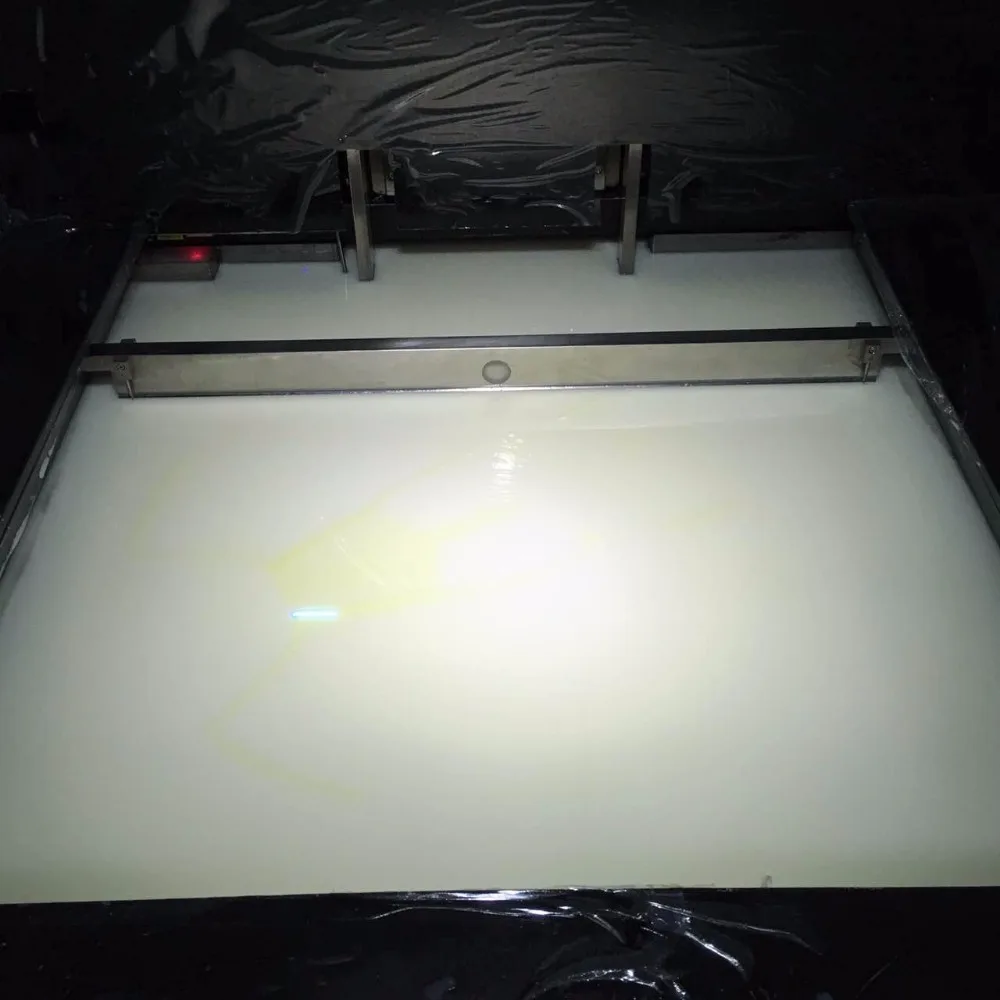

Raw materials kings&material is an ABS like SL resin which has accurate and durable features. It is designed for solidstate SLA platforms.Liquid resin`s medium viscosity, so easy recoating, easy clean parts and machines.Improved strength retained, improved dimensions retention of parts in humid condition .need minimalpart finishing.Long shelf life in machine. kings&material need less part finishing time,easier post-curing ;Buliding accurate and high tough partswith an improved dimensional stability;High quality controls for vacuum casting parts ;Color is more closeto the ABS;Outstanding machinable SLA material. kings& can be applied in master patterns, concept models, general parts and functional prototypes in thefield of automotive, medical and consumer electronics industries.The parts duability building with kings&materialis over 6.5months. Material properties table

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Print Ability:

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Print accuracy High precision, the size of the product structure size error of (+-)0.1mm. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Surface effect Smooth surface, delicate, structured. Clear structure

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

About post-processing

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Application areas | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

KINGS®C series equipment is the first choice for rapid prototyping of automobile, building, lighting, toys, animation, mobile phone, medical, fashion, art, industry and consumer goods. Is also a wise choice of shoe model and other complex process of mold industry. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Requirements of Installation environment | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1.Print workshop should be protected from light,using soft yellow light. 2.Workshop is clean and no dust. 3.The temperature (20-25°) standard is 23°,air humidity 35% -40%, keep ventilated. 4.The printer should far away from vibration source. 5.Voltage is 220V,air conditioning socket must use 16A, printer and oven must use 10A, must be ground wire. 6.Air conditioning requirements:10m² output power 5000W,20m² output power 7500 W,30m² output power >7500W 7.The heat dissipation sheet metal hole remains unobstructed,exhaust fan cover must be covered. 8.The waste water of the dehumidifier must be drained outside the printing workshop,air conditioning and dehumidifier can not be facing the printer. 9.The washing alcohol is placed in the washing room and can not be in the same room as the printing workshop. 10.Photosensitive resin material should be used frequently. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Certification | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

After-sales and service instruction | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1.1 After-sales: We arrange our technical staff in 30 working days to provide global technical after-sales service. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| About company | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shenzhen Jinshi 3D Printing Technology Co.,Ltd. is a high-tech enterprise.The company is based on the 3D digital manufacturing technology, , committed to providing professional solutions of rapid manufacturing for multi industry users by integrating professional resources worldwide in the field of rapid manufacturing.The services include the equipment in the area of rapid prototyping RP,rapid tool RT and reverse engineering RE, various professional rapid processing software,rapid manufacturing integration system,the research and development of rapid prototyping material photosensitive resin,the design and production of various types of rapid prototyping model.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| About payment | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1.Payment treaty FOB: When signing the contract prepaid 50% of the payment, payment before the payment of the balance EXW:When signing the contract prepaid 50% of the purchase price, payment after the payment of the balance 2.Payment method: before T / T; one of the pass; international pay treasure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Shipping and packaging | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1.List of goods

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Packaging | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Delivery method:sea or air Delivert time:30-45days | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FQA | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1.Q : Are you a factory or a trading company? 2.Q : What is your max size for CNC prototype and 3D printing? A : For CNC machine,there is no max size but bigger 3.Q : Can you do OEM customization? A : Yes,we provide OEM services. 4.Q : How long will be your delivery time? 5.Q : What information should I give for detailed quotation? 6.Q : Do you only provide rapid prototyping service? 7.Q : How does your facility handle quality control? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Похожие товары

ЖК-экран для Huawei Mate 20 Pro, сменный ЖК-экран для huawei Mate S Mate10 mate 20 mate30, быстрая доставка

Водонепроницаемая сумка для подгузников с usb-портом

Газовая зажигалка с длинным вырезом, металлическая жесткая трубка, зажигалки для барбекю и кухни, зажигалки с прямыми трубками

Экономичный модульный GRP FRP, Стекловолоконный композитный резервуар для воды на крыше, резервуар для воды для аквакультуры

TNTSTAR TG-1140J+ 2019 New Product 220V/110V Led Fan 42 Inches Designer Ceiling Fan Light Living Room Retractable Ceiling Fan

Высококачественный буровой держатель, карбидный буровой стержень ccmt для вставки 13,95 ~ 14,5 г/см3

Бамбуковые ложки и вилки, Бамбуковая ложка для салата и вилка, посуда двойного назначения, Бамбуковая рисовая ложка

Новые поступления

Новинки товаров от производителей по оптовым ценам