CNC skiving роликовая полировальная машина с китайским производством

- Категория: >>>

- Поставщик: Dezhou Guanlu Precision Machinery Co. Ltd.Dezhou Ltd.

Сохранить в закладки 60739578149:

Описание и отзывы

Характеристики

CNC skiving roller burnishing machine with Chinese manufacture

Machine Overview:

TG20 model deep hole skiving and rolling machine is specially designed for small diameters cold&hot rolling pipes.

The machine features: It completely changed the traditional hydraulic cylinders processing technique, with high cutting speed. The machine make the separately fine scraping, boring and rolling processes become one process, as so the producing efficiency has been improved 5-10 times than the traditional processing type, and the production accuracy is higher too. The labor and material cost will be saved much on hydraulic cylinders producing.

The machine with large power, high rigidity, width processing and technique rang. It’s a cost effective equipment for cylinder making.

Machine main parts brief:

- The machine consist of machine bed, head frame, workpiece rest, oil feeder, oil feeder driving system, boring bar rest, high speed boring bar box, Boring bar carrier feed system, cooling system, Siemens 808 controlling system, auto lubrication system, hydraulic motor and etc.

- Head frame, oil feeder, boring bar rest and boring bar box spindle concentricity installed by hand, in the middle of the machine bed, one end install T leadscrew, parallelism with guide rail is less than 0.05/1000mm, which drive oil press head move to adjust the length of the job. The other end installs ball screw, parallelism with guide rail is less than 0.05/1000mm, drive boring bar infeeding.

- The transmission device supporting bearings adopt Japan NKS stuff, high precision, long lifespan.

- The cooling system is fixed on one side of the machine, Include chips convoryor,oil chamber and filtering system. Coolant flow can get 50-200L/min,user can adjust by hole size. Coolant rated pressure is 0.36-3MPa.

- hydraulic system,which has independent hydraulic pump. One is for oil pressure head move,clamping and head frame job clamping pressure supply. The other is for tool tension and shrinkage. The tool use hydraulic driven system. Independent hydraulic pump,which makes hydraulic system working more steady,accuracy and more easy to maintain.

- Lubricate system: Machine has completely lubricate system,boring bar box carrier,boring bar spindle box use high volume circulation lubrication,boring bar steady rest,oil pressure head,use manual lubricate. The lubricate hydraulic pump is independent installed. which is more steady and easy to maintain.

- Electric control system: Electric control system adopts Siemens control, equips TFT screen. Machine operate can be manual and can be auto control. All low voltage appatus we use Schneider brand. The electric cabinet meets GB5226.1 standard.

Main tech data:

| Item | Parameter |

Working Capacity | Boring Diameter Rang | 38-200mm |

Max. Workpiec length | 2000mm | |

Boring bar spindle | Spindle center height | > 250mm |

Taper of spindle front core | Morse #5 | |

Spindle speed rang | 100-1200r/min(AC servo motor,stepless) | |

Infeeding | Infeeding speed rang | 5-2000mm/min(stepless) |

Carrier rapid moving | 3m/min | |

Motor | Boring bar motor power | 37KW (AC servo motor) |

Infeed motor | 4.2KW(AC Permanent magnet servo motor) | |

Workpiece tighten hydraulic pump motor | 1.5KW (AC motor) | |

Coolant output motor power | 7.5KW, 2sets(gear pump) | |

Automatic lubrication motor power | 0.2KW, 1set | |

Total power (about) | 70KW | |

Others | Coolant system flowing | 200L/min(2 groups) |

Cooling system rated pressure | 3Mpa | |

Filtration accuracy | 40μm | |

Coolant tank | 4CBM | |

Max. Pre-tightening force of head frame against workpiece | 3KN | |

Machine dimensions | 11000X2500X2200mm | |

Machine weight | About 15T |

Machine toolings and sketch:

1. Before shipment, every part of machine will be painted with a layer of anti-rust and water-proof oil to prevent possible erosion during transportation.

2. A plastic cover to wrap around machine parts to enhance corrosion prevention.

3. Export standard fumigated wood cases are measured and specially made for packing.

4. Steel wire will be used to tighten and strengthen the packages inside container.

1. Q: How about the payment terms?

A: We accept T/T 30% prepaid when ordering, the balance paid before shipping.

2. Q: How about the delivery time?

A: Normally, 4-6 months after the deposit.

3. Q: How about the after-sale services?

A: We supply on-site commissioning, operators training, and maintaining services.

4. Q: How about the technical supports?

A: While the customer is meeting the technical problems in processing, our engineer will try their best to give them suggestions and supporting. This is for free to our customers.

Dezhou Guanlu Precision Machinery Co., Ltd. located in Dezhou, Shandong, is a professional manufacturer of deep hole drilling machine (gun drilling machine), deep hole boring machine, deep hole drilling and boring machine, deep hole honing machine, deep hole skiving roller and burnishing machine as well as their relative accessories, such as gun driller sharpen device, BTA deep hole indexable drill head, deep hole boring head, deep hole pressing head and so on. Our company can also offer the customized deep hole machine solutions according to the customers' requirement.

In order to equips suitable deep hole machine tools for our customers, we have workshop to manufacture the cutting tools and accessories. So customer can inform the exactly deep hole diameter and workpiece dimension, we can provide the cutting tools and accessories to them accordingly.

Welcome to visit our factory. And thanks for choosing our deep hole machinery

Any question about deep hole driilling machine, feel free to ask me!

Похожие товары

Высокоточный шлифовальный ролик с ЧПУ и шлифовальная машина

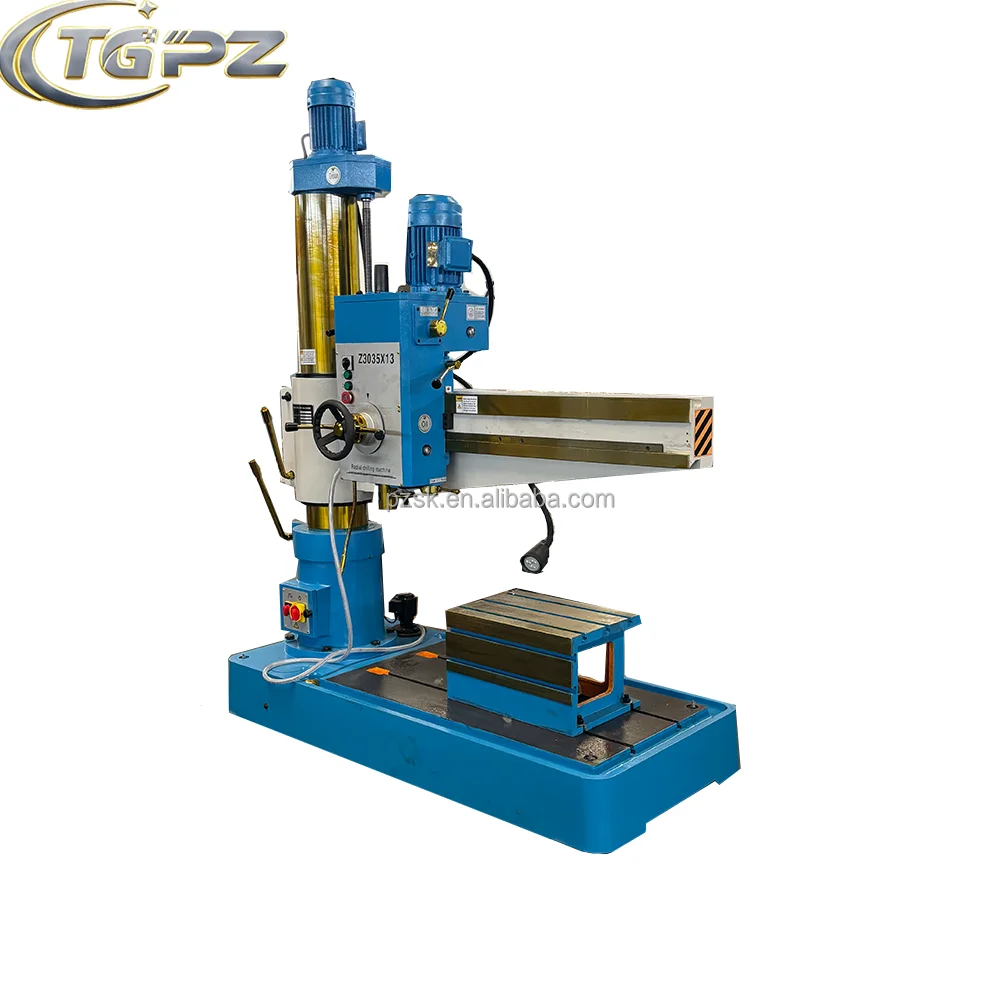

Настольного типа рабочий стол Z3040 / 13 дешевые радиально-сверлильный станок с CE для продажи

Кран части производства соединения машины инструмент скамья нажатие Чак сверлильный станок

Высокая точность Z3035 металлический механический коромысло радиально-сверлильный станок Автоматический подъемный шпиндель автоматическая подача

DNC-1226N20 высокоточный автоматический сменный Многофункциональный фрезерный станок с ЧПУ двумя шпинделями

Электромагнитная муфта передачи рука дрель / radil диллинг машина

DNC-1530HDD сверлильный станок с ЧПУ двумя шпинделями

Новые поступления

Новинки товаров от производителей по оптовым ценам