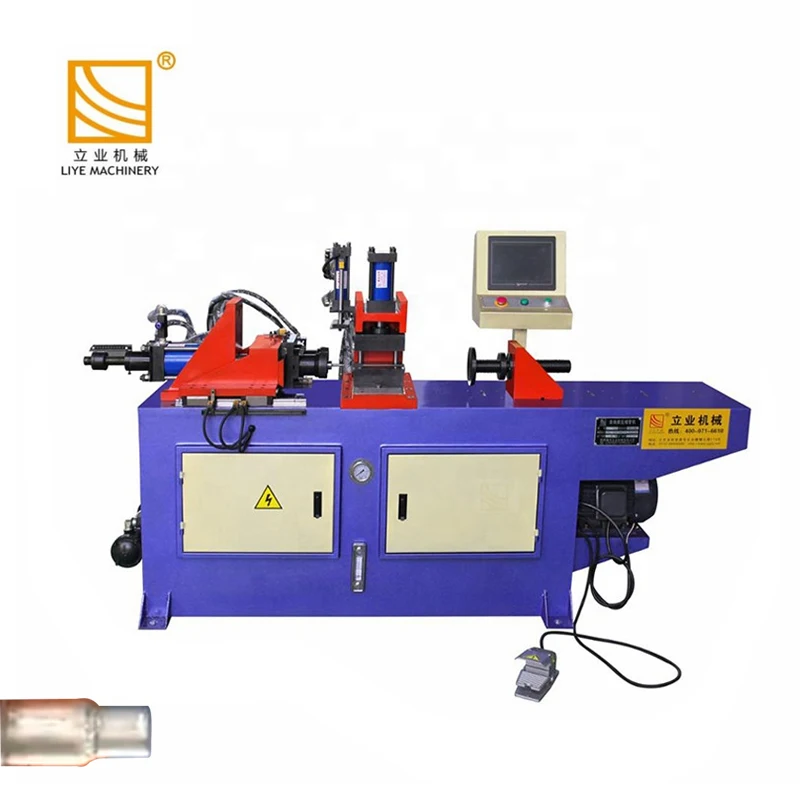

Alibabaschoose Китай углеродная Концевая труба формовочная

- Категория: Станки для развальцовки концов труб >>>

- Поставщик: Suzhou Wonsten Import Export Co. Ltd.

Сохранить в закладки 62106415620:

Описание и отзывы

Характеристики

WONSTEN has progressively become the world's leading manufacturer of metalworking technologies, providing one of the biggest ranges of specialized equipment for the tube and pipe bending industry worldwide. We serve the global market with exceptional machinery and tooling for tube and pipe bending, cutting and end forming purposes – ranging from simple, manual appliances to complex, fully CNC powered systems. WONSTEN designs, develops, retails and services a variety of products for a range of leading industrial industries including automobile and shipping, aeronautics and construction amongst others.

WONSTEN has a proud history of manufacturing in China, Elsewhere, WONSTEN has commercial facilities and a worldwide network of over 20 agencies and technical centers – providing customer support wherever you are!

Our products are designed in our technical department by a team of highly-skilled engineers – we offer competitive solutions without compromising on quality. Over the years, WONSTEN has grown with our customers' requirements and the market demand.

Our products list: manual tube bender, NC series hydraulic semi automatic pipe bending machine, CNC automatic tube bending machine, electrical pipe bender, hairpin bender, pipe cutting machine, tube end forming machine.

Main Features

1. The product is controlled by microcomputer and driven hydraulically. It applies Chinese character display and man-machine conversation operation, and can be operated manually or semi-automatically. One-point foot switch has two functions, startup and emergency stop.

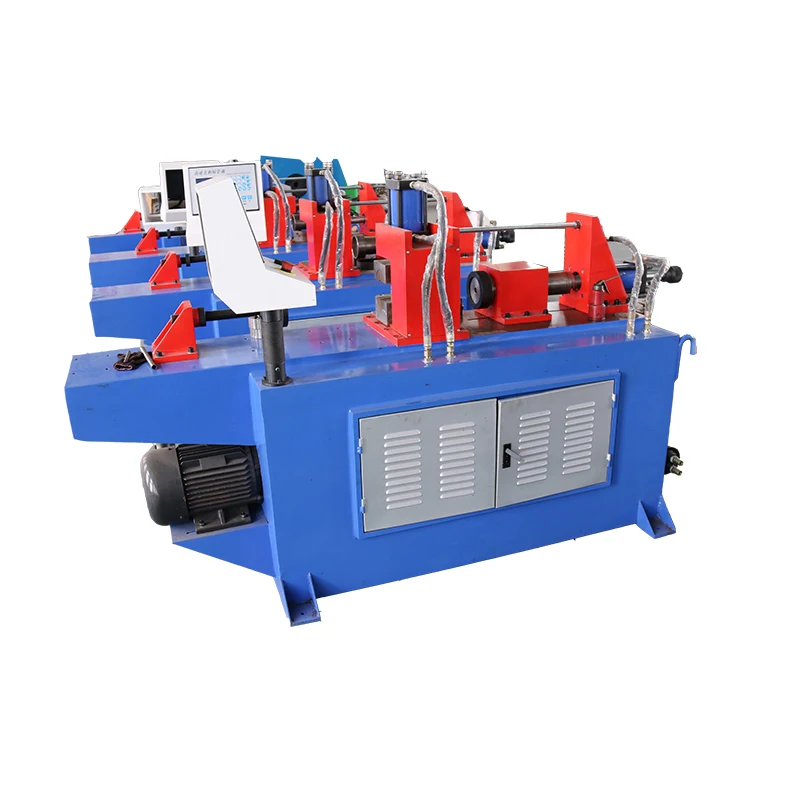

2. With double-station arrangement, pipe end forming machine can shrink the tube for two times simultaneously. Applying linear guideway as the carrier, the product can ensure action without abrasion and ensure good repeatability.

Processing shapes: convex-shaped, concavity-shaped, nodular shape, long partial shape, square shape, topological shape, oblique shape, V-shape, cracking type and flat type. The shape of the mould shall be subject to the object to be processed.

3. The distance between two ends can be adjusted according to the length of tube. (limited to the double-end forming machine only)

4. Single-end clamping or double-end clamping can be carried out according to length of the tube.

5. The product has characteristics including easy operation, stable performance, high work efficiency and high safety factor and it is an ideal device for tube processing industry

Specification/model | SG40NC |

Input Voltage | 380V±10% 50HZ Three-phase power (customizable) |

Control Circuit | 24V |

Maxi. Capacity (Steel Pipe) | 40*2 mm |

Maxi. Process Length | 110mm |

Oil Pump | 17L |

Motor Power | 4kw |

Hydraulic Pressure | 12Mpa |

Size | 2000mm*550mm*1300mm |

Weight | 1100kg |

Похожие товары

Низкий уровень шума металлическая трубка конец формовочная машина делая конусную уменьшительную

Высокочастотная индукционная нагревательная формовочная машина для небольших пластиковых трубок

Медицинские катетеры или канюли, Термоформовочная Машина с трубчатой головкой

Вращающаяся фальцевальная машина Butz для труб с наружным диаметром от 6 до 170

SG60NC Liye Стабильная производительность гидравлическая медная труба формовочная машина окончания трубы

Машина для тиснения металлических труб MINGYI гидравлическая формовочная машина кованого железа

SG-60NC конец трубы формируя машину усаживаясь

Новые поступления

Новинки товаров от производителей по оптовым ценам