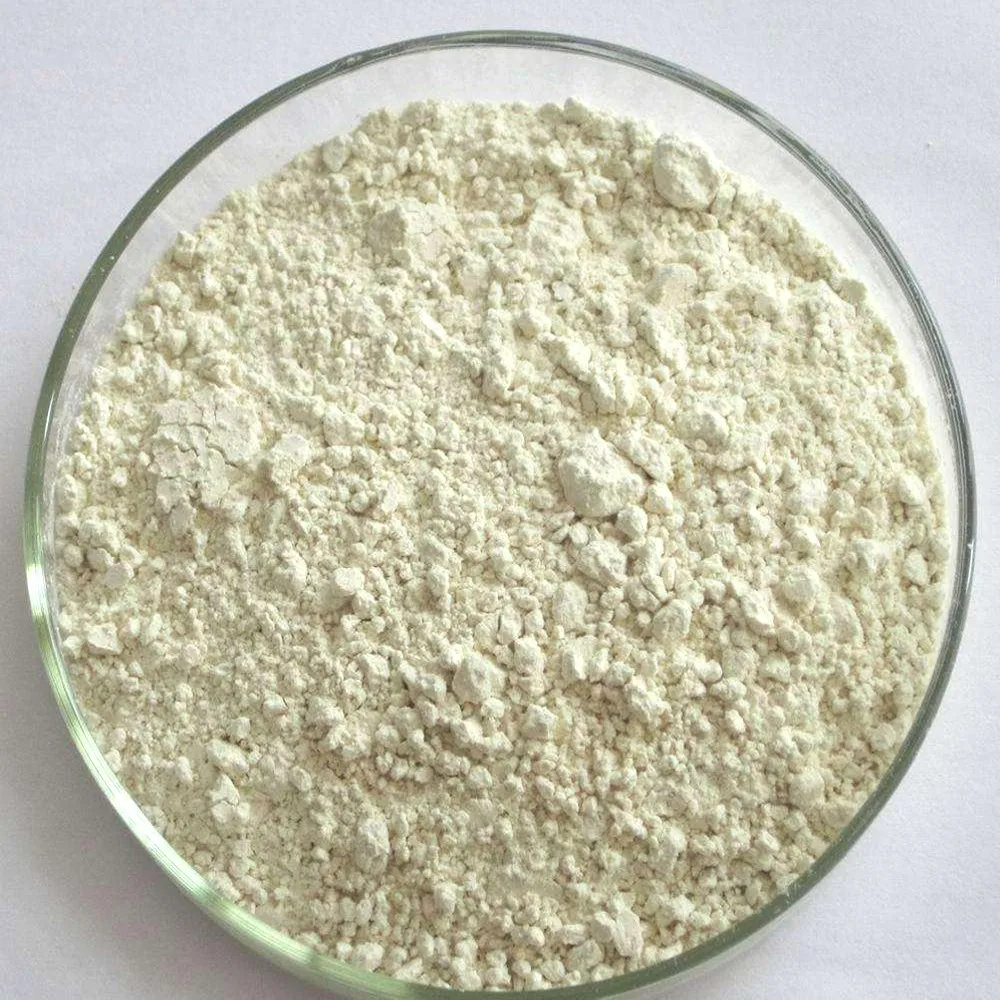

Жидкая фенольная смола

- Категория: >>>

- Поставщик: Hebei Zetian Chemical Co. Ltd.

Сохранить в закладки 62123393198:

Описание и отзывы

Характеристики

Phenol formaldehyde resins (PF) or phenolic resins are synthetic polymers obtained by the reaction of phenol or substituted phenol with formaldehyde. Used as the basis for Bakelite, PFs were the first commercial synthetic resins (plastics). They have been widely used for the production of molded products including billiard balls, laboratory countertops, and as coatings and adhesives. They were at one time the primary material used for the production of circuit boards but have been largely replaced with epoxy resins and fiberglass cloth, as with fire-resistant FR-4 circuit board materials.

There are two main production methods. One reacts phenol and formaldehyde directly to produce a thermosetting network polymer, while the other restricts the formaldehyde to produce a prepolymer known as novolac which can be moulded and then cured with the addition of more formaldehyde and heat. There are many variations in both production and input materials that are used to produce a wide variety of resins for special purposes.

Automotive & Transportation

1 Resins for rubber product to improve reinforcement, vulcanization and formability

Resins for rubber reinforcements, tackifiers for synthetic rubber, vulcanizing agents of rubber and adhesives are widely used in automotive, railways and aircraft industries offering high performance and high reliability.

The main applications are tires, belts, and any other rubber applications (tackifiers have good compatibility with various rubbers).

2 Resins for friction materials with superior heat resistance and good adhesive performance.

We offer phenolic resins as binder for friction materials with superior heat resistance and adhesive performance which are used for brake linings, disc brake pads, clutch plates, clutch facing of transmission and others applications like brake shoe for train, Friction Materials for industrial brake

Electrical & Electronics

1 Resins for copper coating and brush binder

ZT insulation resin coating allows thin coating layer within high Tg for any copper insulation - rotor, stator, wire coating. Brush binder products give high heat resistance and high voltage insulation

2 Components

ZT resins used in condensers (ceramic, film) and copper wire coating.

Building & Construction, Industrial

1 Abrasives

ZT provides resins within high quality standards. These resins have an excellent adhesion to textiles and increased wetting properties. Our resins formulations include additive for "Loading glazing reduction".

2 Refractory

ZT resins are used as binder for manufacturing various carbon refractories. Produced within high quality standards they have increased wetting properties and high KDF.

3 Coatings

ZT resins are used as coating within various industries including food packaging. Produced within high quality standards they have increased chemical resistance, improved adhesion to metal and FDA compliance.

4 Foams

ZT phenolic resins are used for the manufacturing of foam for thermal insulation. The foam produced has closed cells which provide excellent insulation values. Phenolic foam also provides 'by nature' very high heat and fire resistance and low smoke emissions.

ZT phenolic foam for floral application, is an 'open cell' foam which allow absorption of a high amount of water that will be retained for a long time.

5 Laminates

ZT phenolic resins are used as binder for the manufacturing of wood and electrical laminates.

6 Foundry

ZT phenolic resins are used as organic binders in foundry.

7 Adhesives

ZT resins are used as adhesives in various industries.

The company has a complete quality management system, a complete mature set of automation equipment, an imported test of equipment (gel permeation chromatography , cone plate viscometer , fully automatic moisture meter, differential thermal analysis ,gas chromatography) to guarantee product quality and production capacity.

There are tens of senior engineers, engineers, graduate students and under graduate course graduates in the company. At the same time the company has formed all development strategy and relationship with Beijing University of Chemical industry in phenolic resin study and established joint laboratory of high performance phenolic resin to ensure the innovation ability of the enterprise. It has won four patents and two prizes of science and technology by constantly trying to explore.

The company respects knowledge, respects talent and manages for the happiness of staff with the person first and is actively involved in public welfare undertakings. It does good things for itself, for others and for society on the right path and enjoys the happiness.

Now ,we will always unite together, strive, and keep forging ahead and innovate,to make great efforts to push the development strategy of the company to a new stage ,to create a new situation and struggle.

Похожие товары

Yudan Jewelry Manufacturer Custom Stainless Steel silver Irish claddagh pendant

Jekit Заводская поставка GT 6 popts тормозной суппорт кованые передний тормозной суппорт

Заводская цена, пастеризатор из нержавеющей стали для меда, вина, сока, молока, яиц, пива, фруктов, цена

Под заказ 90*150 Большой Эфиопский красный желтый зеленый полосатый флаг Oromo

Новый OEM пульт дистанционного управления Bluetooth5.0 датчик двери и окна сигнализации для домашней системы безопасности

1 кВт, 700 мм, 23 мм, инфракрасная лампа для отверждения краски, керамическая нагревательная лампа, золотые галогенные лампы

Набор постельного белья из 4 предметов с объемным акварельным рисунком единорога, пододеяльником и наволочкой

Новые поступления

Новинки товаров от производителей по оптовым ценам