Алмазные диски 100 мм CBN шлифовальные точильные для tungesten carbide TCT машина заточки лезвий циркулярной пилы

- Категория: Другие шлифовального станка >>>

- Поставщик: Zhengzhou Ruizuan Diamond Tool Co. Ltd.

Сохранить в закладки 62152800017:

Описание и отзывы

Характеристики

Product Description

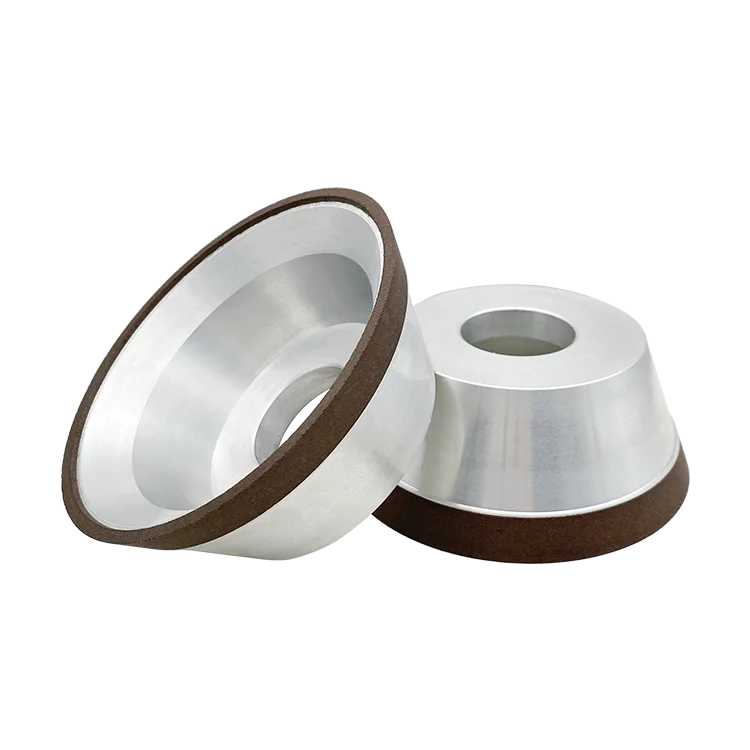

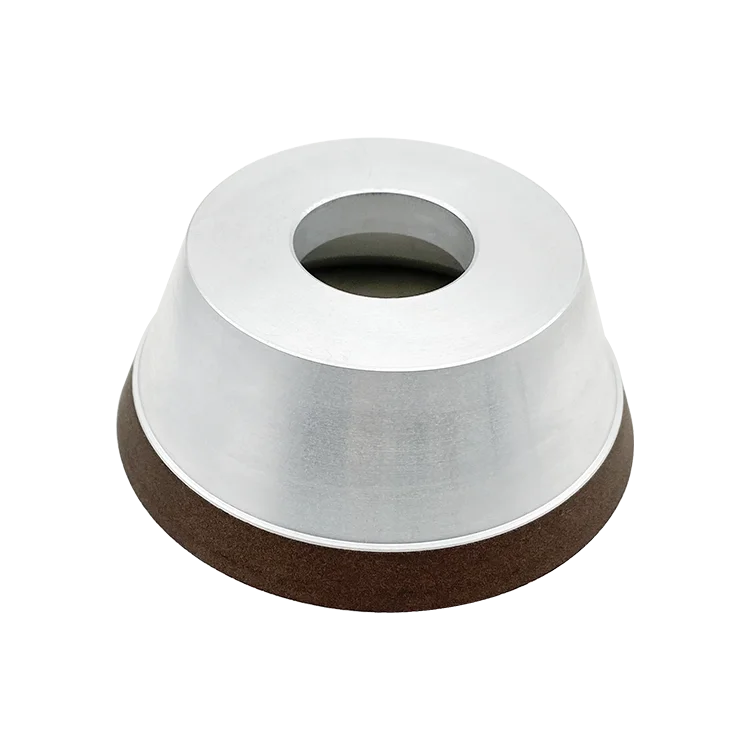

Diamond wheels CBN grinding sharpening discs for tungesten carbide TCT Circular Saw Blade Sharpener Machine

A resinoid bond plain wheel is mainly used for surface grinding ,cylindrical grinding of hand carbide measuring tools ,cutting tools,moulds and also for plunge-cut grinding as well as for grinding.

Product Features.

1. Good self-sharpening and sharp cutting

2. High efficiency and high precision

3. High resistence and best polishing

4. Low roughness of work piece surface

5. Less heat generating

6. Without burning work piece

2. High efficiency and high precision

3. High resistence and best polishing

4. Low roughness of work piece surface

5. Less heat generating

6. Without burning work piece

Product Paramenters

Diamond Grinding Wheels For TCT Circular Saw Blade Sharpener Machine。

Our company deigned an excellent Resin Bond Diamond Grinding Wheels for grinding and sharpening TCT Circular Saw Blades. It performs well on face grinding, top grinding, Teeth Grinding, carbide tips grinding, carbide inserts grinding and also cylinder grinding. And our diamond wheels can work both for wet grinding and also dry grinding. Welcome to wholesale & OEM & ODM.

Diamond wheels CBN grinding sharpening discs for tungesten carbide TCT Circular Saw Blade Sharpener | ||||||||||

Shape | D(mm) | T(mm) | H(mm) | X(mm) | W(mm) | |||||

11V9 | 100 | 25-40 | 16, 20, 31.75, 32 | 2-6 | 3-10 | |||||

125 | 25-40 | 16, 20, 31.75, 32 | 2-6 | 3-10 | ||||||

150 | 25-40 | 16, 20, 31.75, 32 | 2-6 | 3-10 | ||||||

Wheel Shape | 4A2, 12A2, 4BT9, 12V2, 11V2, 12V2, 6A2, 14A1, 12V9, 3V1, 11A2 | |||||||||

Any nonstandard size and grits size can customised (tell us size or drawing is enought) | ||||||||||

Application

Resin bond diamond grinding wheel are mainly used for machining tungsten carbide, ceramic materials, magnetic materials, silicon materials, thermal spraying alloy materials and so on. Resin bond CBN abrasive grinding wheel are mainly used for machining high speed steel, cast iron and so on.

Applicable machine brand: Wright, Vollmer, ABM, Colonial Saw, Armstrong, Amada, Jones Saw Tools, Baileigh Industrial, Foley Belsaw, Thorvie, Bell, Acme, Autool, Nelson, JEFFER, EYAN, Walter, UTMA ,Widma, AKE, STEHLE, SATURN.

Applicable machine brand: Wright, Vollmer, ABM, Colonial Saw, Armstrong, Amada, Jones Saw Tools, Baileigh Industrial, Foley Belsaw, Thorvie, Bell, Acme, Autool, Nelson, JEFFER, EYAN, Walter, UTMA ,Widma, AKE, STEHLE, SATURN.

Saw blade applicable: Simonds, FREUD, FS TOOL, TENRYU, THURSTON MFG.

Selection of grinding wheel elements.

1.hard grinding material, choose the soft, fine grit grinding wheel. Soft grinding material, should choose a hard, coarse grit grinding wheel. By doing this ,grinding wheel loss is small, also not easy to plug.

2. when doing the rough grinding ,in order to increase the productivity, the coarse grit, soft grinding wheel should be chosen,In order to improve the surface quality of the work piece during accurate grinding , the fine grit ,hard grinding wheel should be chosen.

3.the large area of grinding or thin-walled work piece grinding should choose the coarse grit, soft grinding wheel. This wheel is not easy to plug, the surface of the work piece is not easy to burn, the work piece is not easy to deformation.

4. form grinding process to select the fine grit, the small organization, and the hard grinding wheel to maintain the profile of the grinding wheel.

2. when doing the rough grinding ,in order to increase the productivity, the coarse grit, soft grinding wheel should be chosen,In order to improve the surface quality of the work piece during accurate grinding , the fine grit ,hard grinding wheel should be chosen.

3.the large area of grinding or thin-walled work piece grinding should choose the coarse grit, soft grinding wheel. This wheel is not easy to plug, the surface of the work piece is not easy to burn, the work piece is not easy to deformation.

4. form grinding process to select the fine grit, the small organization, and the hard grinding wheel to maintain the profile of the grinding wheel.

Related Products

Electroplated CBN Grinding Wheels for Band Saw

Diamond Resin Grinding Wheels for Chain Saw

Customer Reviews

Company Profile

Our Advantages

Packing & Delivery

PACKAGE:

SINGLE BOX PER WHEEL,

10 t0 20 WHEELS PER CARTON

DELIVERY TIME:

3-30 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

SINGLE BOX PER WHEEL,

10 t0 20 WHEELS PER CARTON

DELIVERY TIME:

3-30 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

Похожие товары

Шлифовальная машина для ножей/точилка для лезвий

1 950,00 $ - 2 000,00 $

Китайский производитель высокого прецизионный плоскошлифовальный станок эффективность двумя осями автоматический AHR PCA-250 плоскошлифовальный станок цена

Строгальное лезвие. Лезвие для резки бумаги/шлифовальный станок с прямым ножом

6 000,00 $ - 6 500,00 $

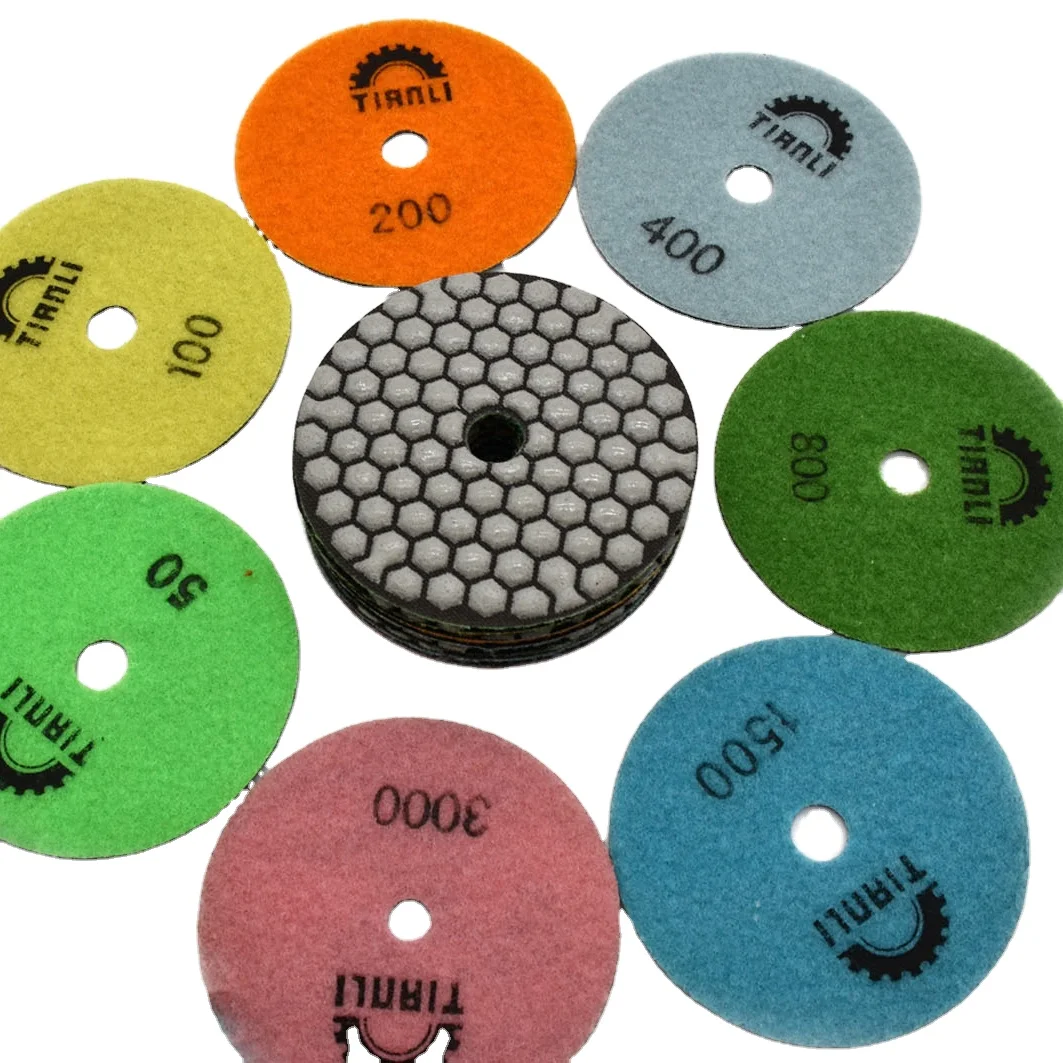

Алмазная полировальная накладка «сделай сам», накладки для сухого шлифования камня, алмазные ручные инструменты, абразивный полировальный диск, инструменты для шлифовальной машины

2,00 $ - 3,00 $

Портативный шлифовальный станок для сверл/3-13 мм шлифовальный станок для сверл/шлифовальный станок для заточки сверл

U2 инструмент точилка Универсальный резак шлифовальный станок Режущий инструмент шлифовальный станок

450,00 $ - 455,00 $

Нож для резки бумаги, машина для заточки лезвий пилы

735,00 $ - 785,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $