GEA N40 широкий зазор свободный поток нержавеющая сталь 304 пластинчатый теплообменник для охлаждения бумаги шлама

- Категория: >>>

- Поставщик: Shandong Propellent Energy Technology Co. Ltd.

Сохранить в закладки 62386188118:

Описание и отзывы

Характеристики

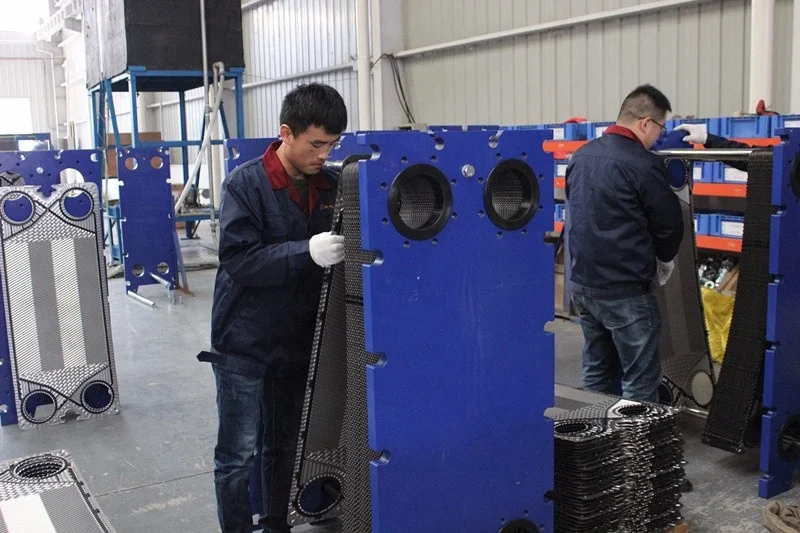

GEA N40 Wide Gap Free Flow Stainless steel 304 plate heat exchanger for cooling Slurry

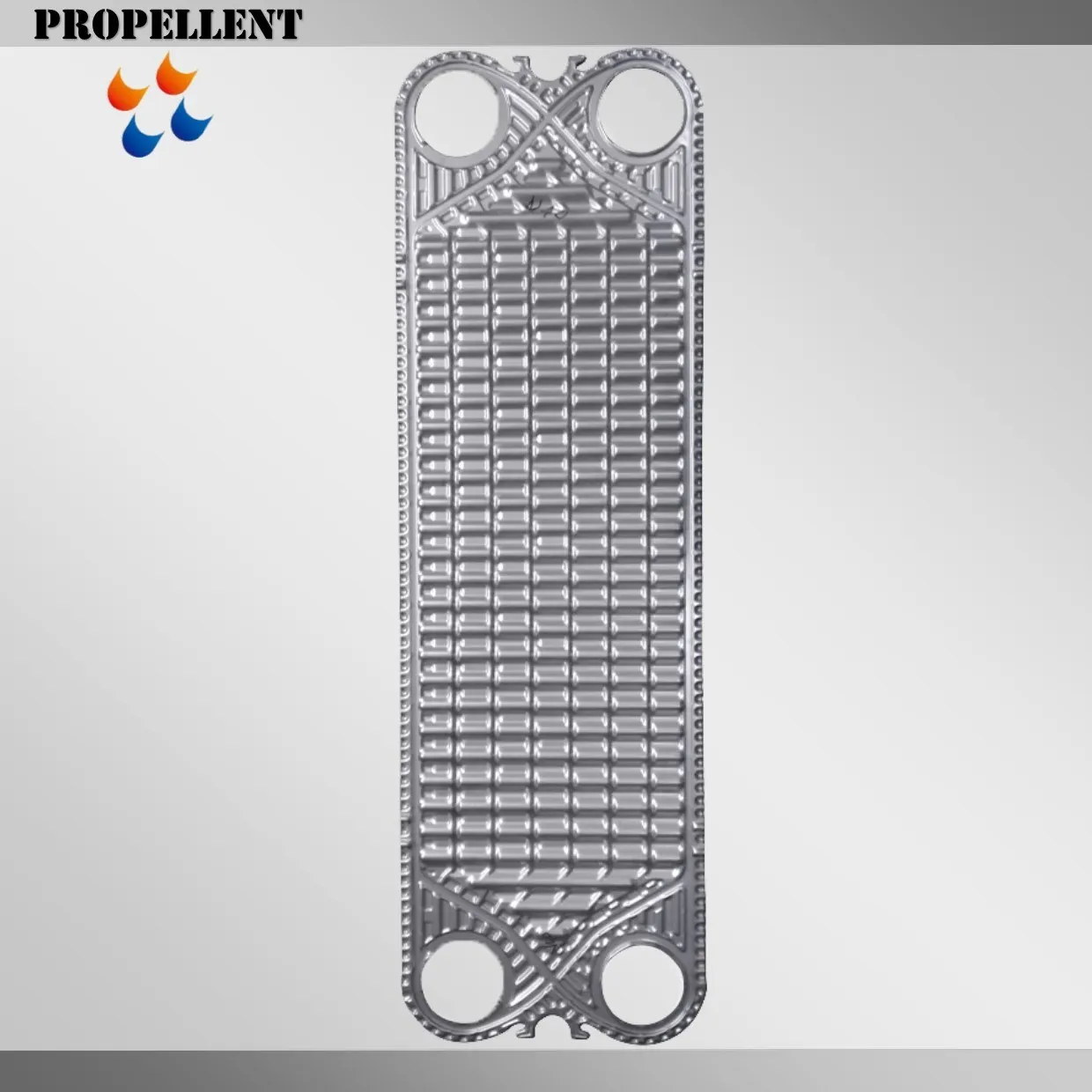

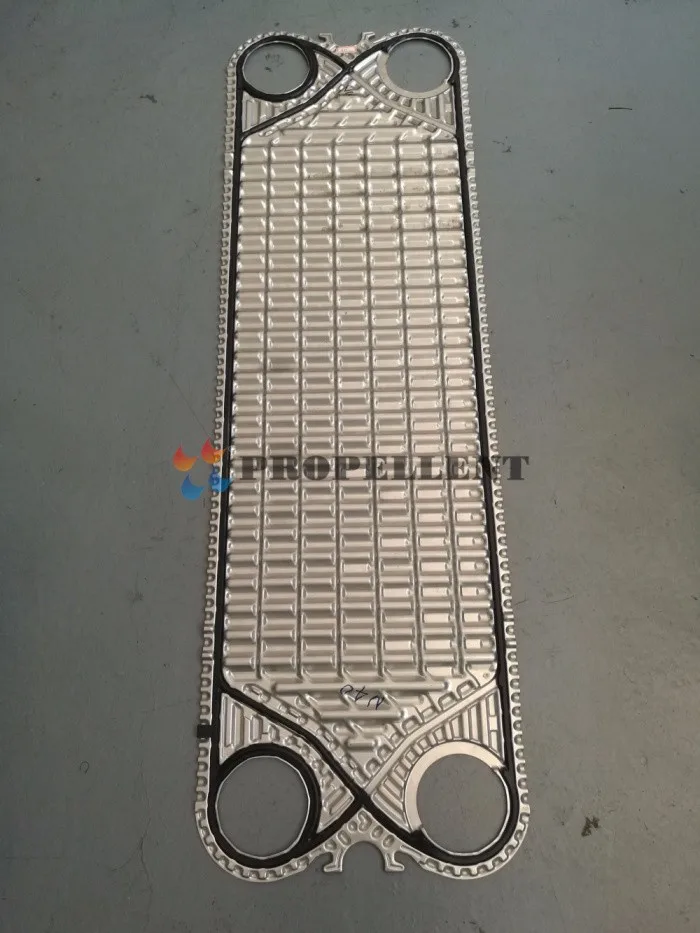

Plate pattern:

Propellent's exclusive plate corrugation pattern allows even flow distribution across the entire plate surface thereby maximizing heat transfer while minimizing fouling rates, plate count, and cost.

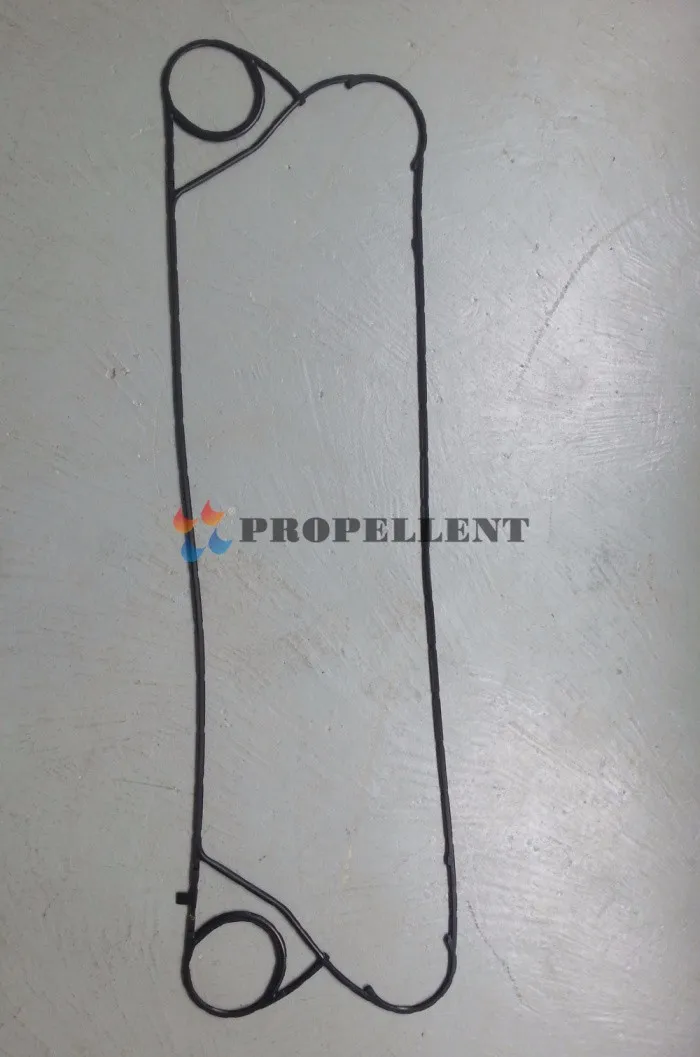

Gaskets

Propellent gaskets work in perfect combination with our plates to ensure worry free operation. Our chamfered opening allows each gasket to settle into position and also prevents the lock tab from being severed. Gaskets can be easily installed without tools or adhesive and self-seat during closing. It takes just seconds to replace a gasket making maintenance quick and easy.

1.High heat transfer coefficient

2.Light weight, small footprint, easy installation,

3.Easy to change heat exchange area or process combination

4.Easy to clean and easy to maintain

5. It can contain all kinds of products to prevent blockage

6. No metal contact point between the plates, absolutely avoiding the occurrence of dead Angle

7. The thickness of 0.4mm-1.0mm plate is conducive to strengthening the rigidity of plate

8. Minimize fouling rate, plate number and cost.

Application areas/occasions:

Propellent, is the Booster and leader of effective heat exchange technology in all industries.

Propellent can be able to offer a full range of heat exchange design calculation in full working condition. We have accumulated rich experience in heating, cooling and waste heat recovery for complex process mediums. Propellent never views separately in the selection of heat exchange equipment applications, but put it in the whole process production line, Therefore, we find the best balance to consider the whole initial investment in equipment and long-term operating costs. We optimize manufacturing processes of our clients and reduce the use of fresh energy to provide our customers maximum value when we find reasonable main points in high heat transfer efficiency and pressure loss.

We seek an understanding of the working conditions for you, and carries on the effective communication with your engineer, to make a perfect solution.It will be more accurate, reducing purchase cost and energy consumption (water, electricity and gas).

Our technical engineers can according to user's working conditions, for our customers to provide professional selection plan and drawings,

and we will choose the appropriate solutions, to provide a stable, efficient service for you.

We will give more consideration to customers' working conditions in order to reduce their equipment purchasing cost and energy consumption of processing operations (water, electricity and gas)

Thank you very much for your reading. If you need anything, please feel free to contact us

Shandong propellent energy technology co. LTD

TEL: 0531-88683005; 88683323; 88681795

FAX: 0531-88681795-8003

Похожие товары

Процветающие драгоценные камни 3A, качественные незакрепленные драгоценные камни, фианиты, ограненные сердцем, цветные фианиты

Конкурентоспособная цена, хорошее качество, высокоэффективный воздушно-воздушный теплообменник

Выскабливание насоса бумаги конденсатора bh250h замена alfa laval mx25b

Оригинальный Amlogic s905x3 Dual Wifi Android 9 0 4K HD плеер HK1 Box X1 X5 128G

Асимметричное джинсовое платье с одним рукавом и поясом, облегающее мини-платье на молнии спереди, женские Клубные вечерние платья

В наличии, клейкая смола, чистота 99.9%, углеводородная Смола C9

новый дизайн термопривод для проветривания теплиц с доводчиком и чёрным штоком

Новые поступления

Новинки товаров от производителей по оптовым ценам