Растение для обогащения 66% цирконовой руды и тяжелых минералов

- Категория: >>>

- Поставщик: Ganzhou Gelin Mining Machinery Co. Ltd.Ganzhou Ltd.

Сохранить в закладки 659618944:

Описание и отзывы

Характеристики

66% Zircon ore & heavy minerals beneficiation plant

Our factory is the leading mining equipments manufacturer who have over 30 years experience in mining field.

We produce full sets mining equipments for processing and separating gold, copper, tin, iron, zircon, rutile, monazite, tungsten, cassiterite, chrome, coltan, manganese, ilmenite, tantalum, niobium, barite and so on.

Main equipments include Trommel, Rotary scrubber, Jig machine, Spiral chute, Shaking table, Magnetic separator, Electrostatic separator, Jaw crusher, Ball mill, Hammer crusher, Double roller crusher, Vibrating screen, Mercury amalgamation, Gold smelting furnace, Diamond washing machine, Gold pan, Drier machine and so on.

We produce full sets mining equipments for processing and separating gold, copper, tin, iron, zircon, rutile, monazite, tungsten, cassiterite, chrome, coltan, manganese, ilmenite, tantalum, niobium, barite and so on.

Main equipments include Trommel, Rotary scrubber, Jig machine, Spiral chute, Shaking table, Magnetic separator, Electrostatic separator, Jaw crusher, Ball mill, Hammer crusher, Double roller crusher, Vibrating screen, Mercury amalgamation, Gold smelting furnace, Diamond washing machine, Gold pan, Drier machine and so on.

Below Different Minerals Washing & Separation | ||||

Coltan | Diamond | Zircon sand | ||

Tantalum | River sand gold | Titanium | ||

Cobalt | Alluvial gold | Tin /Cassiterite | ||

Tungsten | Rock stone gold | Heavy minerals sand | ||

Tantalite | placer gold | Chromium ore | ||

Silica sand | Gold tailing | Monazite | ||

Copper | Clay gold mining | Tungsten ore | ||

Barite | Desert sand gold | llmenite | ||

Chrome | Quartz | Wolfram ore | ||

Iron ore | Coal | Niobium | ||

Manganese ore | Sand gravel | Rutile | ||

Fluorite | Topsoil | Hematite | ||

Products Description

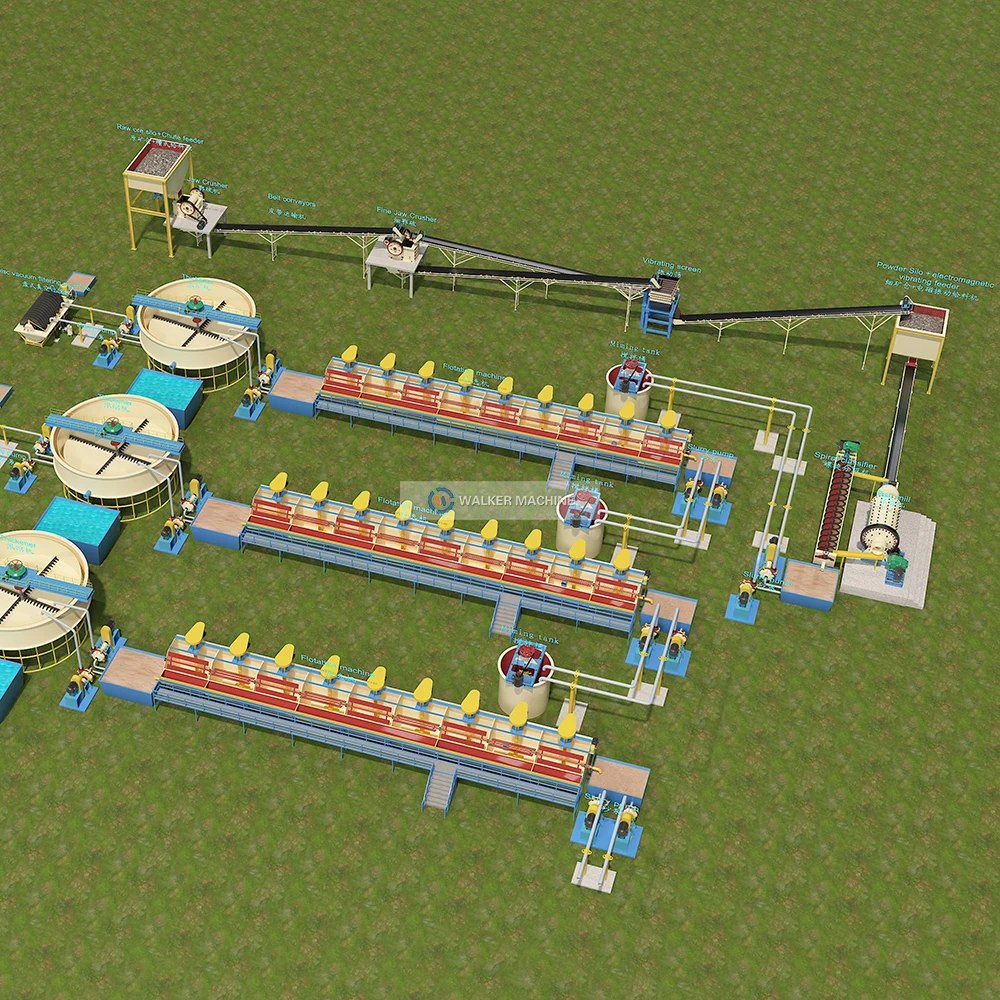

Basic Process for above flowchart

1. Use sand pump feed material directly to spiral separator. If there are some bigger stones in deep areas, can consider use trommel screen to separate out particles +2mm

2. Spiral separator: use two-stages spiral separator, first stage is for rough concentration, the middling from first-stage will go to second-stage to concentrate again to get high recovery ratio.

3. Most of the heavy fractions are magnetic minerals, so in order to remove clean as much as possible, it is better to firstly use our factory special designed four rollers wet magnetic separator to remove magnetite ilmenite and hematite and weak magnetic ore.

4. the gold and zircon and other non-magnetic minerals goes to shaking table for concentration, also use two stages shaking table for getting higher concentration effect. 5. after the electrostatic separator, can get rutile and other minerals, maybe still including some magnetic minerals, so use a high intensity dry process magnetic separator to remove the magnetic minerals again, the zircon will be more high grade up to 66% for sale a good price.

We design different process flowchart depends on customer's actual mining condition.

The Equipment Above Involved

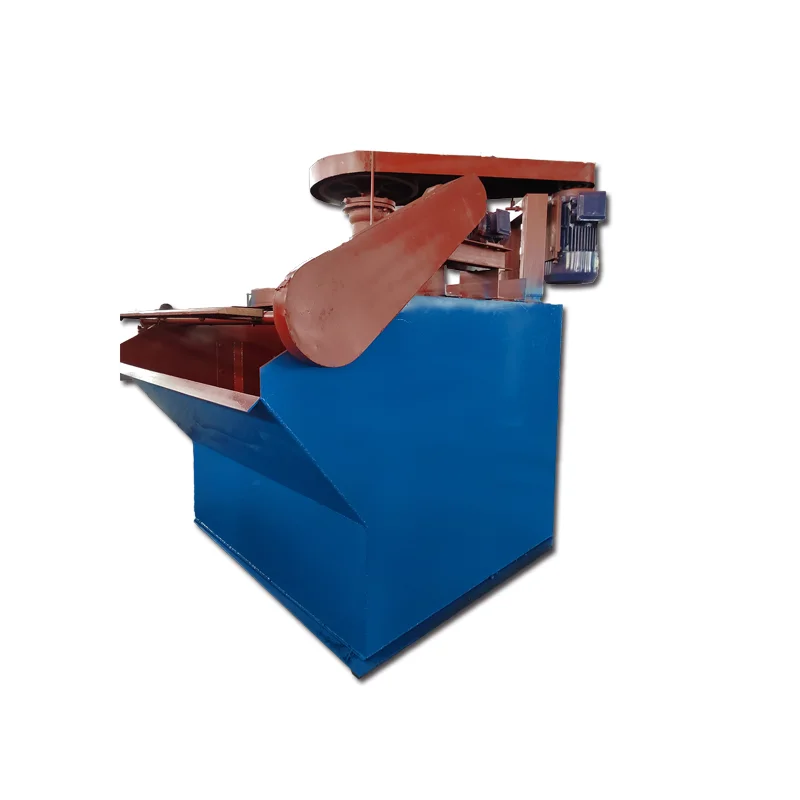

Spiral Chute

Spiral Chute is the best equipment for mining and mineral processing, which combines the characteristics of the spiral

concentrator, shaking table and Centrifugal concentrator. It is made of the fiberglass lined with wear-resistant polyurethane and corundum cover, light moisture proof, anti-rust. It is mainly used for separation and recovery of a wide range of minerals: zircon, ilmenite, rutile, iron ore, chromite, manganese, tin, tantalum and tungsten ore, silica sands, gold, copper and base metals and etc., as well as other non-ferrous metals, rare metals and non-metallic minerals.

concentrator, shaking table and Centrifugal concentrator. It is made of the fiberglass lined with wear-resistant polyurethane and corundum cover, light moisture proof, anti-rust. It is mainly used for separation and recovery of a wide range of minerals: zircon, ilmenite, rutile, iron ore, chromite, manganese, tin, tantalum and tungsten ore, silica sands, gold, copper and base metals and etc., as well as other non-ferrous metals, rare metals and non-metallic minerals.

Parameter for Spiral Chute | ||||||||||||

Model | 5LL-400 | 5LL-600 | 5LL-900 | 5LL-1200 | 5LL-1500 | 5LL-2000 | ||||||

Spiral Diameter (mm) | 400 | 600 | 900 | 1200 | 1500 | 2000 | ||||||

Screw Pitch(mm) | 240/180 | 450/360 | 40405 | 720/540 | 900 | 1200 | ||||||

Dia. Rate | 0.45 | 0.4 | 0.4/0.6 | 0.6 | 0.6 | 0.6 | ||||||

Gradient (°) | 9 | 9 | 9 | 9 | 9 | 9 | ||||||

Num. Of Threads | 1-2 | 1-2 | 2-3 | 2-4 | 2-4 | 2-4 | ||||||

Num. Of Turns | 5 | 5 | 5 | 5 | 5 | 4 | ||||||

Feeding Size (mm) | 2 | 2 | 2 | 2 | 3 | 4 | ||||||

Feeding Density (%) | 25-55 | 25-55 | 25-55 | 25-55 | 25-55 | 30-35 | ||||||

Capacity (t/h) | 0.2-0.5 | 0.8-1.2 | 2-3 | 4-6 | 6-8 | 7-10 | ||||||

Boundary Size L*W*H (mm) | 460*460*1500 | 700*700*2600 | 1060*1060*4000 | 1360*1360*5230 | 1560*1560*5230 | 2120*2120*5230 | ||||||

Weight (kg) | 50 | 150 | 400 | 600 | 800 | 900 | ||||||

Shaking Table

The mineral processing shaking table is a type of gravity separation machine employed for the separation with the fine

materials.It could continuously sort concentrate ore, second-grade ore and tailings. It is applied in roughing, cleaning and

scavenging for dressing coarse sand(2-0.5mm), fine sand(0.5-0.074mm), pulp(0.074mm).

materials.It could continuously sort concentrate ore, second-grade ore and tailings. It is applied in roughing, cleaning and

scavenging for dressing coarse sand(2-0.5mm), fine sand(0.5-0.074mm), pulp(0.074mm).

Parameter for Shaking Table | ||||||||||||||

Model | 6s -7.6 | 6s- 7.6 | 6s- 7.6 | 6s- 4.08 | 6s- 1.95 | 6s- 0.5 | ||||||||

Deck Type | Coarse Ore Deck | Fine Sand Deck | Slurry/Slime Deck | Three Deck Types Available | ||||||||||

Beneficiation Area ㎡ | 7.6 | 7.6 | 7.6 | 4.08 | 1.95 | 0.5 | ||||||||

Deck Size(mm) | Length (mm) | 4450 | 4450 | 4450 | 3000 | 2100 | 1100 | |||||||

transmission end width (mm) | 1855 | 1855 | 1855 | 1320 | 1050 | 500 | ||||||||

Concentrate end width (mm) | 1546 | 1546 | 1546 | 1100 | 850 | 430 | ||||||||

Maximum Feeding Size (mm) | 2 | 0.5 | 0.15 | Sand--2 Slime--0.1 | Sand--2 Slime--0.074 | Sand--2 Slime--0.074 | ||||||||

Feeding Capacity (ton/hour) | 0.8-1.5 | 0.8-1.5 | 0.8-1.5 | 0.4-1.5 | 0.3-0.8 | 0.05-0.2 | ||||||||

Feeding Density (%) | 25-30 | 20-25 | 15-25 | 10-30 | ||||||||||

Stroke (mm) | 16-22 | 11-16 | 8-16 | 6-30 | 12-28 | 9-17 | ||||||||

Frequency (t/s) | 45-48 | 18-53 | 50-57 | 210-320 | 250-450 | 280-460 | ||||||||

Water added (t/h) | 1-3 | 1-3 | 1-3 | 0.4-2 | 0.2-1 | 0.1-0.5 | ||||||||

Transverse Slope of Deck (°) | 2.3°-4. 3° | 1.3°-3.3° | 1° -2° | 0 -10° | 0 -8° | 0 -10° | ||||||||

Longitudinal Slope of Deck (°) | 1.4 | 0.92 | / | / | / | / | ||||||||

Cross-Section Shape of Deck | rectangle | Saw-Tooth/Indention | Triangle | Rectangle, Saw Tooth, Triangle Available | ||||||||||

Motor Power (KW) | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 0.55 | ||||||||

Transimission Mechanism | Eccentric Linkage Type | |||||||||||||

Remark: The tables have three distinct deck designs available. - The coarse ore deck is designed for recovering particles size from 0.5mm to 2mm; - The fine sand deck is designed for recovering fine particles in the range of 0.074mm to 0.5mm; - The slime deck is designed for recovering super extremely fine particles in the range of 0.15mm to 0.074mm. | ||||||||||||||

Magnetic Separator

Our factory produces one roller, two rollers, three rollers, four rollers wet type and dry type high intensity magnetic separator and low intensity magnetic separator, magnetic field intensity from 800 gauss to 20000 gauss. The high gradient magnetic separator is a strong magnetic separator for the screening of weak magnetic minerals. Magnetic separators are widely used for separate magnetic iron ore,Tin ore, ilmenite, titanium ore, hematile, manganese, cobalt, cassiterite, coltan,tantalum, niobium, zircon sand, beach black sands, Monazite ore, Rutile ore,silica purify sand and so on.

Parameter for CTS(N.B) Series One drum(Single drum) magnetic separator | ||||||||||||||||||

Model | Shell size (D.*L) mm | Magnetic induction on shell surface mT | Capacity | Power kw | Rotate speed r/min | Weight Kg | ||||||||||||

Magnetic pole geometric centre | AVG | Max. magnetic strength | T/h | m 3/h | ||||||||||||||

CTS(N.B)-46 | 400×600 | 130 | 160 | 1~3 | 5 | 1.1 | 45 | 600 | ||||||||||

CTS(N.B)-66 | 600×600 | 145 | 170 | 5~10 | 16 | 1.1 | 40 | 705 | ||||||||||

CTS(N.B)-69 | 600×900 | 145 | 170 | 8~15 | 24 | 1.1 | 40 | 830 | ||||||||||

CTS(N.B)-612 | 600×1200 | 145 | 170 | 10~20 | 32 | 2.2 | 40 | 990 | ||||||||||

CTS(N.B)-618 | 600×1800 | 145 | 170 | 15~30 | 48 | 2.2 | 40 | 1330 | ||||||||||

CTS(N.B)-712 | 750×1200 | 120 | 155 | 180 | 15~30 | 48 | 3 | 35 | 1500 | |||||||||

CTS(N.B)-718 | 750×1800 | 120 | 155 | 180 | 20~45 | 72 | 3 | 35 | 2100 | |||||||||

CTS(N.B)-918 | 900×1800 | 148 | 165 | 190 | 25~55 | 90 | 4 | 28 | 2900 | |||||||||

CTS(N.B)-924 | 900×2400 | 148 | 165 | 190 | 35~70 | 110 | 4 | 28 | 3500 | |||||||||

CTS(N.B)-1018 | 1050×1800 | 148 | 165 | 190 | 40~75 | 120 | 5.5 | 22 | 4000 | |||||||||

CTS(N.B)-1021 | 1050×2100 | 160 | 240 | 280 | 45~88 | 140 | 5.5 | 22 | 4500 | |||||||||

CTS(N.B)-1024 | 1050×2400 | 160 | 240 | 280 | 52~100 | 160 | 5.5 | 22 | 5000 | |||||||||

CTS(N.B)-1030 | 1050×3000 | 160 | 240 | 280 | 65~125 | 200 | 7.5 | 22 | 6200 | |||||||||

CTS(N.B)-1218 | 1200×1800 | 160 | 240 | 280 | 47~90 | 140 | 5.5 | 19 | 5800 | |||||||||

CTS(N.B)-1224 | 1200×2400 | 160 | 240 | 300 | 82~120 | 192 | 7.5 | 19 | 6200 | |||||||||

CTS(N.B)-1230 | 1200×3000 | 160 | 240 | 280 | 80~150 | 240 | 7.5 | 19 | 7200 | |||||||||

CTS(N.B)-1530 | 1500×3000 | 180 | 240 | 300 | 90~170 | 270 | 11 | 14 | 8100 | |||||||||

CTS(N.B)-1540 | 1500×4000 | 180 | 240 | 300 | 115~220 | 350 | 11 | 14 | 9300 | |||||||||

* CTS is suitable for the roughing and cleaning of particle size in 6-0mm; * CTN is suitable for the cleaning and scavenging of fine particle size in 0.6-0mm , and for heavy medium in coal; * CTB is suitable for the roughing and cleaning of ores in size of 0.5-0mm, especially suitable for the cleaning of ores in size of 0.15-0 mm. | ||||||||||||||||||

Electrostatic Separator

High tension (High voltage) electrostatic separator is an dry separating equipment in the high voltage electric field, which eliminate the mineral according to the differences of materials electricity nature.

It adopts the different electrical property of all minerals and materials in the nature to realize the separation.The common

minerals like ilmenite, magnetite, cassiterite,and native gold etc,have good conductivity property while quartz, zircon, feldspar, calcite, scheelite,and silicate minerals have poor conductivity property,then the electric separator adopts their different electrical property to realize the separation.

PS:those materials mentioned above are hardly qualified when gravity concentration, flotation and magnetic separation are adopted, such problem can be well solved after electrostatic separation is adopted.

It adopts the different electrical property of all minerals and materials in the nature to realize the separation.The common

minerals like ilmenite, magnetite, cassiterite,and native gold etc,have good conductivity property while quartz, zircon, feldspar, calcite, scheelite,and silicate minerals have poor conductivity property,then the electric separator adopts their different electrical property to realize the separation.

PS:those materials mentioned above are hardly qualified when gravity concentration, flotation and magnetic separation are adopted, such problem can be well solved after electrostatic separation is adopted.

Parameter for Electrostatic Separator | ||||||||||||||||

Model | GELIN-ES1 | GELIN-ES2 | GELIN-ES3 | GELIN-ES4 | GELIN-ES5 | GELIN-ES6 | GELIN-ES7 | GELIN-ES8 | ||||||||

Rollers Qty | 2pcs | 2pcs | 2pcs | 2pcs | 2pcs | 4pcs | 4pcs | 4pcs | ||||||||

Roll Size | 120*750mm | 120*1500mm | 165*1500mm | 220*1500mm | 320*1500mm | 165*1500mm | 220*1500mm | 320*1500mm | ||||||||

Roller speed | 0-800r/min | 0-800r/min | 0-800r/min | 0-800r/min | 0-500r/min | 0-500r/min | 0-500r/min | 0-500r/min | ||||||||

Working voltage | 0-45kv | 0-45kv | 0-45kv | 0-45kv | 0-45kv | 0-60kv | 0-60kv | 0-60kv | ||||||||

Motor(kw) | 1.1 | 1.1 | 1.5 | 1.5/2.2 | 3 | 3/4.4 | 3/4.4 | 6 | ||||||||

Feed size | 0-2mm | 0-2mm | 0-2mm | 0-2mm | 0-2mm | 0-2mm | 0-2mm | 0-2mm | ||||||||

Capacity | 0.3-1t/h | 0.5-2t/h | 1-2.5t/h | 1-3t/h | 2-3t/h | 1-4t/h | 2-5t/h | 4-8t/h | ||||||||

Dimension L*W*H (mm) | 1300*800*1800 | 2100*1000*3100 | 2100*1250*3100 | 2100*1330*3100 | 2100*1500*4500 | 2100*1330*4500 | 2100*1500*4500 | 2100*2800*4500 | ||||||||

Packing & Delivery

Packing

Normally the machines are taken apart before delivery and are packed by suitable packing ways, the packing ways are as below:

1. Nude packing.

2. Bundle packing.

3. Grass rope packing.

4. Water proof packing.

5. Wooden pallets packing.

6.Wooden box or carton box packing.

Delivery

Usually the equipments are delivered aboard by tracks,trains,or container(sea transportation). and some spare parts or very small goods also support to send by express, our company have built good relationships with large cargo agent and shipping companies which guarantee our products delivered safely and promptly.Sea transportation includes three delivery ways as below:

1.40HQ container: used for goods without overlength, overheight and overweight;

2.FR(Flat Rack) container:suitable for large equipments with overlength,overheight like ball mill,excavator,etc.

3.Bulk cargo shipment (LCL): used for some goods without loading in full container,normally it requires good packing with marks for safety and easy to be trackable.

Normally the machines are taken apart before delivery and are packed by suitable packing ways, the packing ways are as below:

1. Nude packing.

2. Bundle packing.

3. Grass rope packing.

4. Water proof packing.

5. Wooden pallets packing.

6.Wooden box or carton box packing.

Delivery

Usually the equipments are delivered aboard by tracks,trains,or container(sea transportation). and some spare parts or very small goods also support to send by express, our company have built good relationships with large cargo agent and shipping companies which guarantee our products delivered safely and promptly.Sea transportation includes three delivery ways as below:

1.40HQ container: used for goods without overlength, overheight and overweight;

2.FR(Flat Rack) container:suitable for large equipments with overlength,overheight like ball mill,excavator,etc.

3.Bulk cargo shipment (LCL): used for some goods without loading in full container,normally it requires good packing with marks for safety and easy to be trackable.

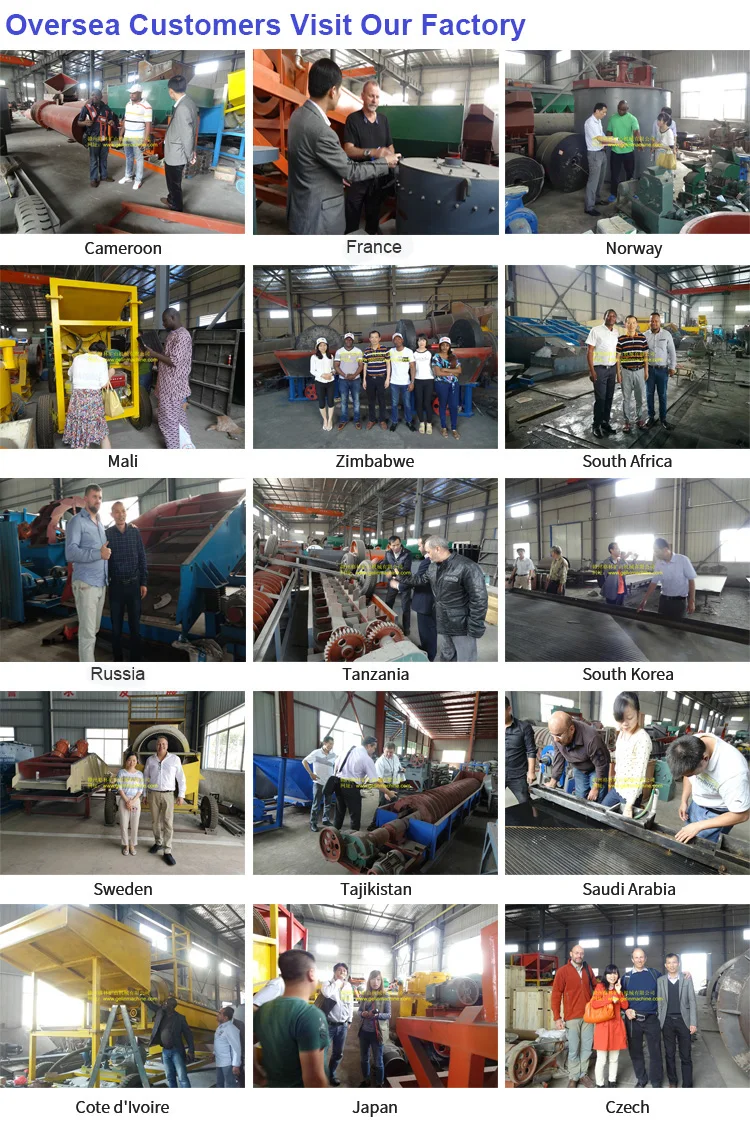

About Company

Ganzhou Gelin Mining Machinery Co., Ltd is an over 30 years professional manufacturer and exporter of mining machinery for crushing, screening, grinding, flotation, separation etc. in China. Gelin have a complete service system which can provide customer full service in mining field and after sales service.By now, Gelin’s equipments and services are exported to over 60 countries,include America, Russia, India, Africa, Brazil, Chile,South Africa,Zambia etc.

Sincerely welcome customers to visit our factory.

One Stop solution for beneficiation plant service:

1.Engineering consulting available,it makes clients have a comprehensive understanding of beneficiation plant,including mine value,useful elements,mineral processing technology,plant scale,essential equipments,etc.

3.After reaching agreement with client,we start to engineering design,including planning,investigation,data collection, project evaluation etc. and then comes up with design scheme of beneficiation plant construction and working drawings.

1.Engineering consulting available,it makes clients have a comprehensive understanding of beneficiation plant,including mine value,useful elements,mineral processing technology,plant scale,essential equipments,etc.

2.Arrange mineral beneficiation experiment after received the material sample and beneficiation test report will be done after test.

3.After reaching agreement with client,we start to engineering design,including planning,investigation,data collection, project evaluation etc. and then comes up with design scheme of beneficiation plant construction and working drawings.

4.Manufacturing the necessary equipments and arrange the shipment.

5.Complete services for Installation and commissioning and technical training(operating training,common problem solving training).

After-sale Service

Regularly visit customers to provide after- sale technical supports and to solve problems of beneficiation plant. For equipments supplied,we could provide one-year warranty and provide spare parts with preferential price in the long term and be responsible for any problems with the them.

FAQ

Q: Are you a trading company or a factory?

A: We are a factory at Shicheng county with 110 workers,6 workshops covered 17,000㎡ and office covered 2,500㎡. Welcome to visit our factory at anytime.\t

A: We are a factory at Shicheng county with 110 workers,6 workshops covered 17,000㎡ and office covered 2,500㎡. Welcome to visit our factory at anytime.\t

Q: What is your payment terms?

A: By TT(Telegraphic Transfer), 100% or 40% Deposit before production and 60% balance payment will be paid off after sending product pictures and before loading from factory.

A: By TT(Telegraphic Transfer), 100% or 40% Deposit before production and 60% balance payment will be paid off after sending product pictures and before loading from factory.

Q: How long is the guarantee period of your products?

A: The guarantee period is 1-2 years, pls ask staff for more details. And we will supply lifelong technical support service and the spare parts at lowest cost.

Q: Is it possible to produce customized products ?

A: Yes, most of our products are produced as required.

A: Yes, most of our products are produced as required.

Q: Is it possible to provide sample for your factory to do ore-dressing experiment?

A: Yes, engineering consulting is available and we’d like to arrange mineral beneficiation experiment after received your sample and provide the test report.

A: Yes, engineering consulting is available and we’d like to arrange mineral beneficiation experiment after received your sample and provide the test report.

For more details, please refer to our website: www.gelinmachinery.com

Related Products

Похожие товары

6 ячеек Sf1.2 флотационная машина wanshuntong флотационные ячейки цена

3 800,00-4 600,00 $

Промывка песка большой емкости используется циклонный десандер для разделения шлама гидроциклонный

890,00-1 178,00 $

Высокопроизводительное горно-шахтное оборудование для разделения флотации завод по переработке серебряной руды

10 000,00-30 000,00 $

Сухой Тип постоянный магнитный барабанный сепаратор

Мелкомасштабное оборудование для добычи золота мини-Майнер оловянной руды концентрирующий гравитационный сепаратор вибрирующий стол Gemini на продажу

2 985,00-3 150,00 $

Сухой или влажный магнитный сепаратор частиц для отделения сверхтонкой железной руды от ganue

4 800,00-5 000,00 $

Экспериментальный магнитный сепаратор для минералов

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $