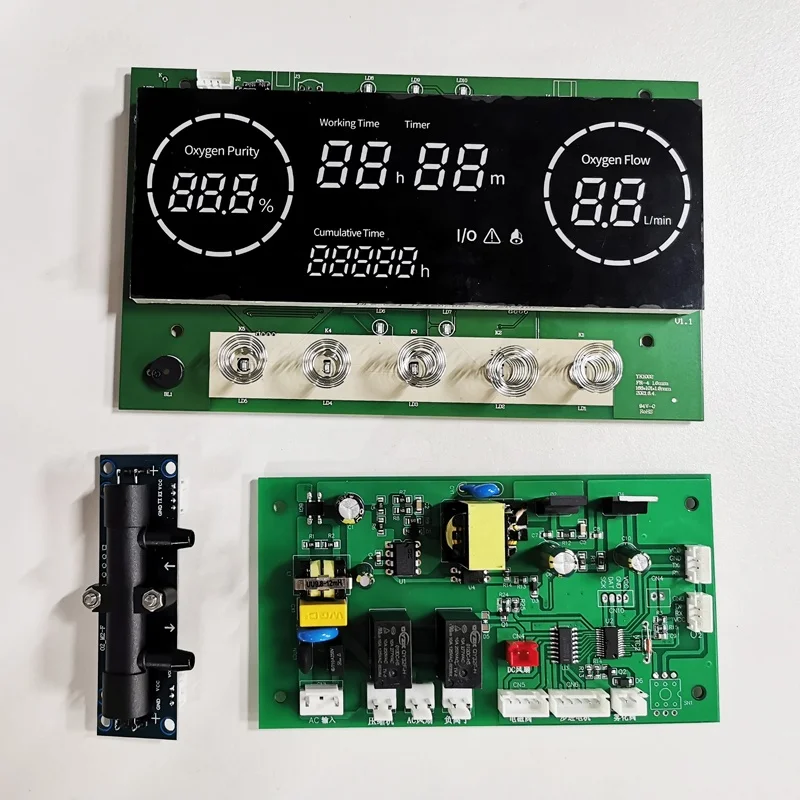

circuit design schematic PCB PCBA prototypes control circuit board for oxygen concentrator

- Category: PCB & PCBA >>>

- Supplier: Shenzhen Soffa Technology Co. Ltd.

Share on (1600234654949):

Product Overview

Description

Most PCB or PCBA factories only accept clients Geber files and BOM list, then mount the parts on PCB. A part of them call PCB layout as designing or developing. When there is any unreasonable designs in your files, they cannot detect it, let alone to improve it for you. In this case, you will find the finished product defective rate is high, or assemly efficiency is very slow when you are assemle the PCBA into the plastic or metal enclosure.

For Shenzhen Soffa, we originally work on ODM finished products including mechanical design for plastic enclosure, developing MCU software, PCB layout, circuit schematic, 3D prototypes, tooling, plastic injection, PCBA manufacturing, enclosure and PCBA assembly, packaging, shipping to overseas. We expericed the whole product developing process since 2006. Therefore, we are very familiar or an expert at making the product from nothing to all. When we receive your files, we will consider the possible defective, production convenience and efficiency, cost economic, etc.

To workwith us, it will save you a lot of time and money, as well as reduce the product developing time and defective rate. What is more, we can change the software right away if you want to change anything.

| Name | in stock oxygen concentrator control board pcb assembly with O2 sensor connector cable LCD screen |

| PCB material | FR4, rigid board, |

| Voltage | DC24V |

| Density of oxgen |

up to 98% |

| Concentrating capacity per hour |

10 liter ( standard )

For others like 1L, 5L, 15L, 20L, we can make based on customer orders. |

|

Contents include for 1 set |

* 1 x main control board * 1 x LCD screen board * 1 x O2 sensor |

|

Sample lead time |

1 to 2 days |

Our existing PCBA design control circuit board for oxygen concentrator includes:

1) AC main power circuit

2) Circuit transfer AC220V to DC12V

3) 200 mAh rechargeable battery

4) Charging circuit

5) Lithium battery protection circuit

6) Alarm warining circuit

7) Lower voltage inspect circuit

8) Valve starting circuit

9) Microprocessor with software

10) Connectors include:

1 Battery connector ( 2.54 *2P)

2 valves connectors ( 2.54 *2P)

1 AC mains' ( 3.96 *2P)

1 ON OFF start switch ( 2.54 *2P)

1 compressor' ( 3.96 *2P)

We welcome customized design for this oxygen concentrator control circuit board design or pcb prototypes making.

Drawing of oxygen concentrator control board:

More pictures oxygen concentrator control board PCB:

We have professional and experienced Electronic engineers and Mechanical engineers with over 15 years plastic and electronics products production experiences from designing, tooling, production and packing. These enable us to predict possible problems during production, so as to improve at our designs to reduce unnecessary production procedures during production and assembly, to increase production and assembly efficiency.

With professional engineering teams and 7 SMT lines, we can provide PCBA and enclosure prototypes in 7 days. Our 7 SMT lines can reach 8 million points in 1 day to finish urgent delivery orders. we can guarantee the fastest delivery in 3 days.

Soffa produces strictly according to PBA standard IPC-A-610B. Each process will be quality checked before handling to the next production process. Our careful and responsible IQC, QA and QC team execute quality inspections based on AQL4.0. With special testing machines such as X-ray, AOI, ICT, FCT and eye checking through the whole production process, we achieve a high-quality level with less than 0.1% defective rate.

Our main services include:

* PCBA software and hardware developing based on your target price.

* PCBA manufacturing based on your Gerber file and BOM list.

* Turn-key solutions for both plastic enclosure and PCBA developing, production and delivery.

All products are in conformity with CE, ROHS, FCC. We provide free sample based on freight collect in 1 to 2 days. For sample with customized size and power watt, we can provide as fast as 3 days.

Shipping way:

We accept customer appointed shipping agency for pick up order at our factory. And clients can also use our company cooperated shipping agents. We have below shipping ways.

1) Courier: DHL, Fedex, TNT, around 5 days to arrive at your hand.

2) Air shipping: around 5~7 days arrive at your nearest airport

3) Sea shipping: around 10 to 30 days depends on seaport.

( We have warehouse in UK, Germany, USA. We accept DDP service.)

Q: What service you provide?

A: We do below 2 kinds service:

1) OEM: Clients provide Gerber file, software and BOM list, we manufacture PCBA.

2) ODM: Clients provide function descriptions, and we will develop the hardware, software and PCBA production.

3) Turn-key solution for both outer enclosure and PCBA electronics: clients provide electronics function descriptions and enclosure sketches, and we will work on mechanical designing, PCBA developing, prototypes, tooling, assembly, testing, packing and delivery.

Q: What files you required for quotation?

A: 1) PCBA production: Gerber file and BOM list, testing and packing requirements.

2) PCBA development: detailed function descriptions in word file.

3) Enclosure and PCBA development: detailed function descriptions in word file and sketches in JPG or AI file.

Q: How long does a PCBA prototypes take?

A: 1) If clients provide Gerber file and BOM list, it takes as fast as 3 days.

2) If we develop PCBA, it takes around 3 days to 15 days depending on how complicated the functions.

Q: How can you ensure the quality?

A: First, IQC will check all incoming raw materials before SMT production.

Second, there is Initial Sample Inspection before mass production. If all OK, the mass production will be arranged.

Third, during each SMT process, there are routing inspector and each process in-charging person eye checking welding points and parts.

Last but not the least, there are X-ray, AOI, magnifier, customized fixture functions tests after SMT finished, as well as eye checking during DIP, ICT (In-Circuit Tester) and FCT (Function Check Test ) by customized fixture after reflow, eye checking during cleaning and before packing processes.

Q: What is your defective rate in mass production?

A: less than 0.2%.

Q: How to do with defected products?

A: Firstly, there is 0.3% spare based on your order.

If you received defectives more than 0.3% from mass production, we will send you equal quantity for replacement by DHL air on our charge.

Q: How can I contact you for a quotation?

A: Please send us an email: soffa at soffa.cn

or whatsapp /phone call us at 0086 158 2045 0819.

Or write in below square frame for “ Inquiry “.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices