Customized square metal plate embossing machine production line

- Category: >>>

- Supplier: Dongguang Baibo Tile Machine Co. Ltd.

Share on (1600249988894):

Product Overview

Description

Product Overview

Equipment capacity

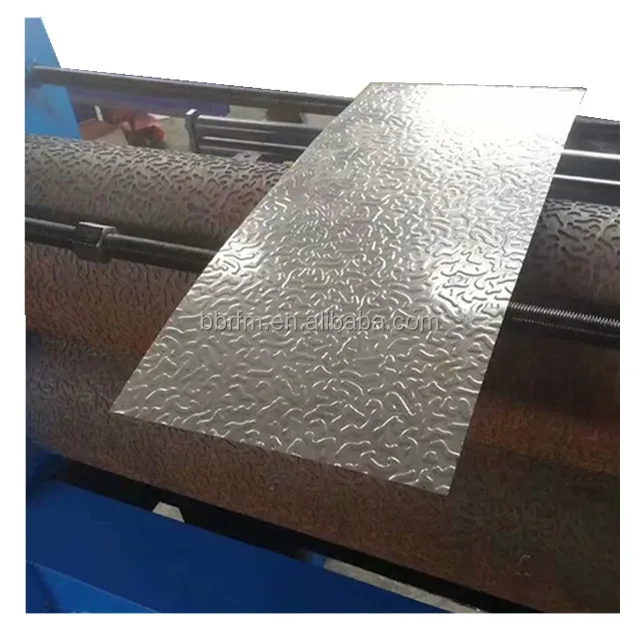

Automatic steel plate embossing machine is used to produce the sheet with beautiful decorative pattern and figure and

arabesquitic.

Differnt shapes patern sheet can used as many decorative building, and used as floor sheet to be skidproof, especialy for the

ship.

baibo metal floor sheet emsbossing machine can help you emboss different pattens on the metal which could be used for many

building, such as: wall, panel or others.

The Alloy embossing roller for steel sheet embossing rollers fuctions main by the two big rollers, there are patterens on the

rollers, so when then rollers rolling, and the sheet between the two sheet is running, there will appear the patterns on the

sheet.

Finest-quality Steel Embossing roller floor embossing machinery can work manual by workers from the feeding and the embossing, and

also be formed by the full automatic by PLC controling box

rollers, so when then rollers rolling, and the sheet between the two sheet is running, there will appear the patterns on the

sheet.

Finest-quality Steel Embossing roller floor embossing machinery can work manual by workers from the feeding and the embossing, and

also be formed by the full automatic by PLC controling box

FEATURES AT A GLANCE

Trapezoidal Metal Roofing Sheet Tile Roll Forming Machine Trapezoidal Metal Roofing Sheet Tile Roll Forming Machine is one of most

popular metal building material making machines,it can produce many kinds of trapezoidal tile/panels,which can be widely used in

many scenes,like school,gym, warehouse,etc.

1 | Good quality: We have a professional designer and experienced engineer team and the raw material and accessories we use are good. |

2 | Good service: we provide the technical support for whole life of our machines. |

Guarantee period: within one year since the date of finishing commissioning. The guarantee covers all the electric, mechanic and hydraulic parts in the line except for the easy-worn parts. | |

4 | Easy operation: All machine controlling by PLC computer controlling system. |

5 | Elegant appearance: Protect the machine from rust and the painted color can be customized. |

Warranty

1. Warranty: 1 year warranty from date of machine begin running in buyer's factory.

2. Guarantee:

3. 1: Guaranteed against malfunctions due to manufacturing defects for 1 year after date of machine begin running in

buyer's factory.

Repairs will be made free of charge.

2. Guarantee:

3. 1: Guaranteed against malfunctions due to manufacturing defects for 1 year after date of machine begin running in

buyer's factory.

Repairs will be made free of charge.

2: Repairs will not be performed free of change even during the guarantee period in the follow circumstances

- Damage occurs due to a natural disaster

- Malfunction occurs due to user error

- Malfunction occurs due to modifications

- Malfunction occurs due to further movement or shipment after installation

3: when machine is in buyer's factory, seller's engineer will be to buyer's factory.Air ticket, transportation cost, hotel, meals

and 100USD per day as salary shall be for purchaser's account if manufacturer's engineer has to be send to purchaser's factory.

- Damage occurs due to a natural disaster

- Malfunction occurs due to user error

- Malfunction occurs due to modifications

- Malfunction occurs due to further movement or shipment after installation

3: when machine is in buyer's factory, seller's engineer will be to buyer's factory.Air ticket, transportation cost, hotel, meals

and 100USD per day as salary shall be for purchaser's account if manufacturer's engineer has to be send to purchaser's factory.

Automatic operation, arc size can be adjusted

Hydraulic automatic feeder

High quality CNC box and hydraulic station

Similar products

company information

Meeting you, growing with you, enjoying with you, supporting you!

certification

Packing&Shipping

Packing of Tile Roll Forming Machines: Usually because it is very large, so we use wooden package to make it more stable.Or

shipping by containers, which will be more convenient and safty. Shipping of Tile Roll Forming Machines: You can choice use our

agent or your agent all is OK. Just share all your ideas to us, we'll sharing one satisfied planing.

shipping by containers, which will be more convenient and safty. Shipping of Tile Roll Forming Machines: You can choice use our

agent or your agent all is OK. Just share all your ideas to us, we'll sharing one satisfied planing.

FAQ

1. what is your guarantee period?

Guaranteed against malfunctions due to manufacturing defects for 12 months from the date of loading.

2. Do you provide training for my workers?

The machine has been installed and tested well before shipping. It is easy to operate.

Normally speaking, our customer follows the instruction book and can operate the machine well.?

You can also come to our factory to check the machine and learn how to operate before shipping. It only needs 2 hours and you can

operate well.

3. I do not know about the machine and do not know how to install it. Can you install the machine in my factory?

If you need us to send engineers to your factory, you will pay for the travel expense such as visa, round tickets, hotel, food

Salary of 80 USD per day per person (from departure from our factory, until we are back to our factory). You also need to take

care of his safety.

4. What is included in the machine?

The process for work: decoiler→feeding→roll forming→measuring length→cutting to length→product to stand

The whole line includes a manual decoiler, roll forming machine and product stand. when you get the machine in your factory, you

just need to do following 3 things, and then you can start working.

a. Put the machine on the flat level ground.

b. Inject gear oil and hydraulic oil.

c. Connect 3 phase electric wire.

Guaranteed against malfunctions due to manufacturing defects for 12 months from the date of loading.

2. Do you provide training for my workers?

The machine has been installed and tested well before shipping. It is easy to operate.

Normally speaking, our customer follows the instruction book and can operate the machine well.?

You can also come to our factory to check the machine and learn how to operate before shipping. It only needs 2 hours and you can

operate well.

3. I do not know about the machine and do not know how to install it. Can you install the machine in my factory?

If you need us to send engineers to your factory, you will pay for the travel expense such as visa, round tickets, hotel, food

Salary of 80 USD per day per person (from departure from our factory, until we are back to our factory). You also need to take

care of his safety.

4. What is included in the machine?

The process for work: decoiler→feeding→roll forming→measuring length→cutting to length→product to stand

The whole line includes a manual decoiler, roll forming machine and product stand. when you get the machine in your factory, you

just need to do following 3 things, and then you can start working.

a. Put the machine on the flat level ground.

b. Inject gear oil and hydraulic oil.

c. Connect 3 phase electric wire.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices