Mini 20 Ton hand press manual hydraulic press small hydraulic press

- Category: Hydraulic Press >>>

- Supplier: Shandong Aolai Machinery Co. Ltd.

Share on (1600366934251):

Product Overview

Description

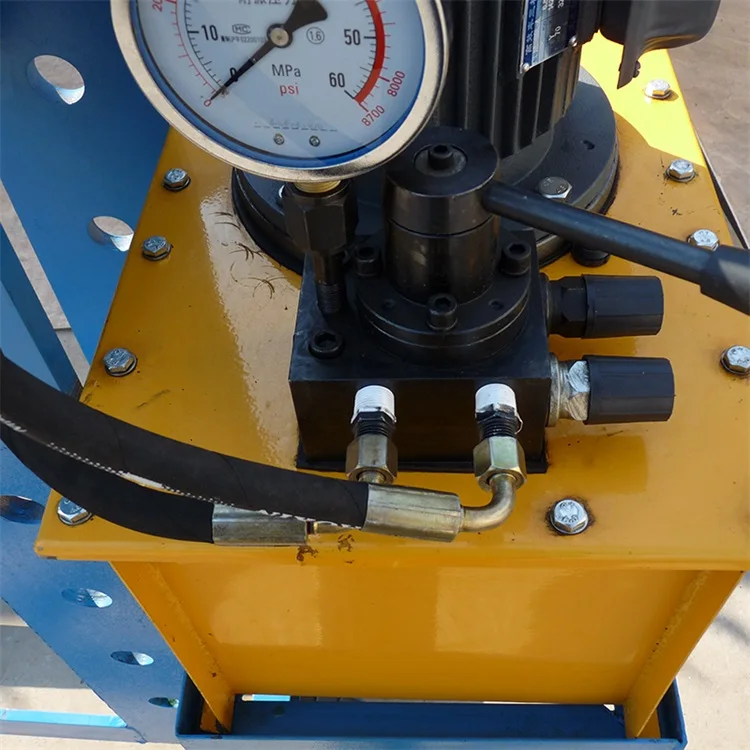

The hydraulic press mainly has a frame, a hydraulic system, a cooling system, a pressurized cylinder, an upper mold and a lower mold. The pressurized cylinder is installed on the upper end of the frame and connected with the upper mold, and the cooling system is connected with the upper mold and the lower mold. It is characterized in that the lower end of the frame is equipped with a mobile worktable and a mobile oil cylinder connected with the mobile worktable, and the lower mold is placed on the mobile worktable.

Products Description

Method of operation

Delivery valve operation

1) Before operating the fuel delivery valve, turn on the loading speed indicating device, and quickly turn the regulator to an appropriate position to keep the indicating plate at a certain speed. For example, in the 3000kN range, the loading speed of 50kN/s should be adjusted to 1r/min. In addition, if the loading speed of 12.5kN/s is to be used on the 1500kN range, the loading speed should be adjusted to 0.5r/min (the speed is measured by a stopwatch). The speed of the indicating plate remains unchanged after adjusting.

2) In order to make the oil output by the oil pump enter the oil cylinder quickly, the piston is raised quickly to reduce the auxiliary time, and the oil delivery valve can be opened larger at the beginning. When the test piece starts to load, pay attention to operating the oil delivery valve handle, adjust the oil delivery valve according to the loading speed of the test piece, that is, the pointer movement should be synchronized with the indicator plate, especially when it is close to the broken tonnage. The loading speed is higher or lower than the indicator plate, so as not to affect the accuracy of the experiment.

After the test piece is broken, slowly unscrew the oil return valve to return the oil in the oil cylinder to the oil tank. At this time, the pendulum slowly drops, and the active needle of the dial returns to the zero position. However, it should be noted that it is not necessary to completely drain the hydraulic oil in the oil cylinder to make the working piston fall too low, as long as it can accommodate the next test piece and set it smoothly. After the next test piece is put in place, close the oil return valve and the working piston Rise and maintain the original speed and load. After the work is completed, the oil delivery valve can also be closed (if the oil return valve is not opened at this time, the working cylinder has low pressure oil supply to make the piston rise without load)

Product Specification

Slide Stroke (mm):140 |

Machine Type:H Frame Hydraulic Press |

Ejector Force (kN):200 |

Return Force (kN):200 kN |

Voltage:380/220/customer appoint |

Dimension(L*W*H):600*300*1270 |

Weight (T):0.15 T |

Motor Power (kw):1.5 kw |

main feature

1. This machine adopts hydraulic transmission, highly professional integrated valve block, super large flow diameter, so that the system pressure loss is small, and the sealing performance is good.

2. The use of cartridge valve, electro-hydraulic proportional valve and unique oil circuit design make the hydraulic system perfect. Even if it works under long-term heavy load, the system will not appear to be inadequate.

3. The system is designed with a pre-discharge device, which completely eliminates the hydraulic shock.

4. Advanced fast device to ensure your class output.

5. The electrical part adopts imported SY Sanyi automatic control system, which has strong anti-interference ability and low failure rate.

6. The machine body adopts a horizontal integral steel structure, which has high strength and good stability. It does not need to install foundation screws.

7. The electrical part adopts PC control, which has strong anti-interference, high degree of automation and simple operation.

8. The hydraulic station adopts integral sy Sanyi professional valve block and Datong valve installed to prevent oil leakage, reduce the oil temperature of the system, and improve the stability of the system.

9. The frame part adopts integral steel castings, which improves the reliability, stability and service life of the equipment.

10. The oil cylinder adopts tandem oil cylinder, which improves the movement speed and production efficiency.

11. According to the user's working conditions, it is additionally equipped with a spiral automatic feeder and a chain automatic discharger, which reduces the labor intensity of the workers.

1. This machine adopts hydraulic transmission, highly professional integrated valve block, super large flow diameter, so that the system pressure loss is small, and the sealing performance is good.

2. The use of cartridge valve, electro-hydraulic proportional valve and unique oil circuit design make the hydraulic system perfect. Even if it works under long-term heavy load, the system will not appear to be inadequate.

3. The system is designed with a pre-discharge device, which completely eliminates the hydraulic shock.

4. Advanced fast device to ensure your class output.

5. The electrical part adopts imported SY Sanyi automatic control system, which has strong anti-interference ability and low failure rate.

6. The machine body adopts a horizontal integral steel structure, which has high strength and good stability. It does not need to install foundation screws.

7. The electrical part adopts PC control, which has strong anti-interference, high degree of automation and simple operation.

8. The hydraulic station adopts integral sy Sanyi professional valve block and Datong valve installed to prevent oil leakage, reduce the oil temperature of the system, and improve the stability of the system.

9. The frame part adopts integral steel castings, which improves the reliability, stability and service life of the equipment.

10. The oil cylinder adopts tandem oil cylinder, which improves the movement speed and production efficiency.

11. According to the user's working conditions, it is additionally equipped with a spiral automatic feeder and a chain automatic discharger, which reduces the labor intensity of the workers.

Our Company

Packaging And Shipping

Our Service

Before sale

1. Quick response

2. Professional technical consulting services

3. Provide a variety of related information about the product

2. Professional technical consulting services

3. Provide a variety of related information about the product

On sale

1. Delivery on schedule

2. Strict factory acceptance

3. Use negotiated or suitable packaging for transportation

2. Strict factory acceptance

3. Use negotiated or suitable packaging for transportation

After sale

1.24 hours technical support

2. Long warranty

3. Sufficient spare parts guarantee

2. Long warranty

3. Sufficient spare parts guarantee

FAQ

1: What kind terms of payment can be accepted?

A: For terms of payment, L/C, T/T, D/A, D/P, Western Union (can be) could accepted

2: What certificates are available in Machinery?

A: For the certificate, we have CE, ISO,EPA(USA),CCC

3: What about the delivery time?

A: 7-20 days after receiving the deposit.

4: What about the warranty time?

A: 12 months after shipment or 2000 working hours, whichever occuts first.

5. What about the Minimum Order Quantity?

A: The MOQ is 1 pcs

6.What about the service?

1). Quick response to every inquiry.

2). Professtional and detailed answer to any of customer's questions.

3). Strict QC and in time delivery.

4). Offer all relative material for customer to know and better use the machine.

5). Periodically after service follow up, offer any necessary support if needed.

6).For the new machine, within determined limits, the manufacture guarantees warranty for a period of 12 months after bought or 20

00 working hours(whichever comes first).

7).The warranty includes repairation or replace the parts for free which were proved to be defective in origin by the technical

department of the manufacture.

8).The repairation or replacement for the parts should not exceed the warranty period.

9).The warranty is valid on the condition of all the terms listed in the contract was observed.

A: For terms of payment, L/C, T/T, D/A, D/P, Western Union (can be) could accepted

2: What certificates are available in Machinery?

A: For the certificate, we have CE, ISO,EPA(USA),CCC

3: What about the delivery time?

A: 7-20 days after receiving the deposit.

4: What about the warranty time?

A: 12 months after shipment or 2000 working hours, whichever occuts first.

5. What about the Minimum Order Quantity?

A: The MOQ is 1 pcs

6.What about the service?

1). Quick response to every inquiry.

2). Professtional and detailed answer to any of customer's questions.

3). Strict QC and in time delivery.

4). Offer all relative material for customer to know and better use the machine.

5). Periodically after service follow up, offer any necessary support if needed.

6).For the new machine, within determined limits, the manufacture guarantees warranty for a period of 12 months after bought or 20

00 working hours(whichever comes first).

7).The warranty includes repairation or replace the parts for free which were proved to be defective in origin by the technical

department of the manufacture.

8).The repairation or replacement for the parts should not exceed the warranty period.

9).The warranty is valid on the condition of all the terms listed in the contract was observed.

Contact Us

Shandong Aolai Machinery Co., Ltd

Tel/Wechat/Whatsapp:+8613325178055

Linkedin: 13325178055

Facebook: 13325178055

Facebook: 13325178055

Email : al13325178055@hotmail.com

We Recommend

Hydraulic Manual Punching Machine

US $1100-$1200

500 ton hydraulic press sheet metal forming press machine

US $35000-$38000

New Arrivals

New products from manufacturers at wholesale prices