Building Materials Galvanized Metal Roof Steel Floor deck Sheet Roll Forming Machine

- Category: Tile Making Machinery >>>

- Supplier: Nantong Super Machinery Co. Ltd.

Share on (1600600993112):

Product Overview

Description

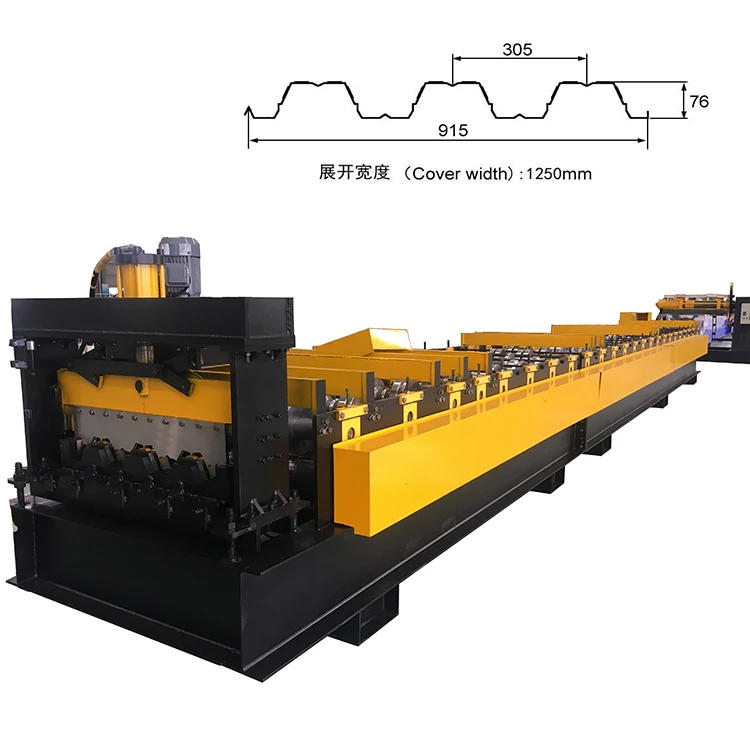

915mm Steel Floor Metal Deck Scaffolding Roll Forming Machine

Features of Floor Decking Roll Forming Line:

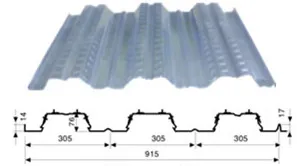

The metal deck produced by floor decking roll forming line has high strength with big wave length. It adheres well to concrete. Used on high building, it not only saves steel mold plate, but also reduces the weight of storey. With the same bearing capacity, it economized steel and cuts down investment accordingly.

We can also supply the customized machines.

Applications of Floor Decking Roll Forming Line:

The finished products are widely used in floor flat, after make embossing of the sheet, it will increase the strength between the steel and concrete, thereby increasing the floor of the fastness.

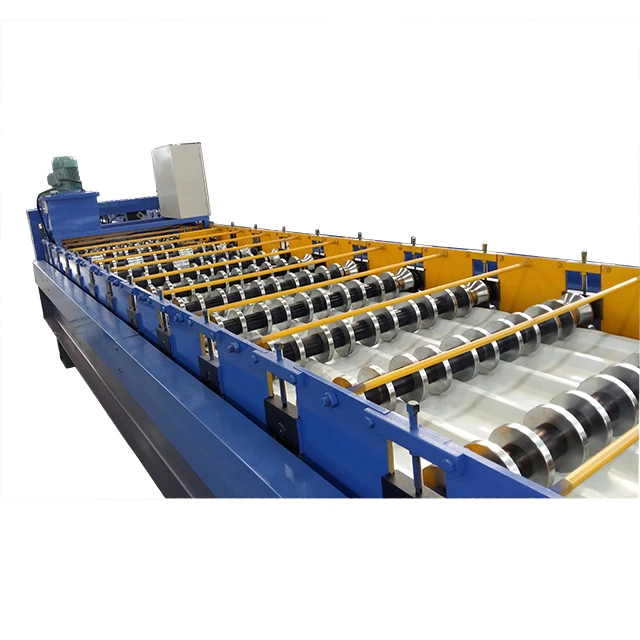

Process Flow of Floor Decking Roll Forming Line:

Uncoiler -Feeding -Straightening-Roll Forming -Cutting-Exit Rack

Machine Configurations of Floor Decking Roll Forming Line:

1.Manual De-coiler or Hydraulic De-coiler 5t (optional)

2.Feeding device

3.Straightenting device

4.Roll Forming Machine

5.Cutting device

6.PLC control system

7.Exit Rack or Pneumatic Auto Stacker 6m or 12m (Optional)

8.Hydraulic Station

Profile Drawing of Reference:

Machine Parameters

No | Item | Parameter |

01 | Material feeding width | 925~1250mm |

02 | Material thickness | 0.8~1.3mm |

03 | Uncoiler | Manual Uncoiler |

04 | Loading weight | 5ton |

05 | Forming speed | 8-15m/min |

06 | Forming Steps | 26~35 stations |

07 | Shafts materials | 45# high quality steel |

08 | Shafts diameter | 76mm |

09 | Roller materials | 45# high quality steel, hard chrome coated 0.05mm |

10 | Transmission | Chains-sprockets |

11 | Main motor power | 2x11kw |

12 | Cutting blade | Cr12 with quenched treatment 60-62 |

13 | Hydraulic power | 4kw |

14 | This machine will automatically measure and cut the length and quantity as per clients set on the PLC touch screen | |

15 | Length cut Accuracy | ±1mm |

16 | PLC control system | Omron Japan |

17 | Frequency converter | TAIAN |

18 | Screen | TouchWin |

19 | Voltage | 380V/50HZ/3Phase |

20 | Total weight | Approx 15t |

21 | Overall dimensions | 15600x1500x1300mm |

PACKAGE:

LCL Loading Packaging: Steel pallet and plywood case.

——FCL Loading Packaging: Steel pallet with plastic film.

——Shipping: by sea

Our Service:

- Provide Pre-sales Consultant & On-purchase service 8 hr × 6 days per week

- Reply within 24 hours

- Provide relevant product information

- Answer questions if request

- Give technical suggestion

² Provide After-sales service 24hr × 7days per week

- Test the machine before shipment

- Provide technical guidance relate to use the machine

- Supply one-year warranty period for the machine

- Provide the spare parts at cost price after warranty period

- Collect the feedback for the machine working

- Provide long-term technical assistance.

OUR CUSTOMERS

About

Nantong Super Machinery Co.,Ltd. Founded 1996, is the top manufacturer in China Specializing in steel metal working machine and a variety of equipment solutions for the global supplier.

The business principal of our factory is "Customer First and Faith Foremost" and what we pursue is to meet the requirements of customers and do better for them. Businessmen from at home and abroad are welcomed to our factory for business talks and work hand in hand for the prosperous future.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices