Хорошее обслуживание, профессиональный ПВХ пластиковый потолочный профиль, панель с автоматическим тиснением, экструзионная линия, делая машину

- Category: Plastic & Rubber Processing Machinery >>>

- Supplier: Jiangsu Sunlins International Trade Co. Ltd.

Share on (1600863789767):

Product Overview

Description

Good Service Professional Pvc Upvc Plastic Ceiling Profile Panel Extrusion Line Making Machine

Specifications:

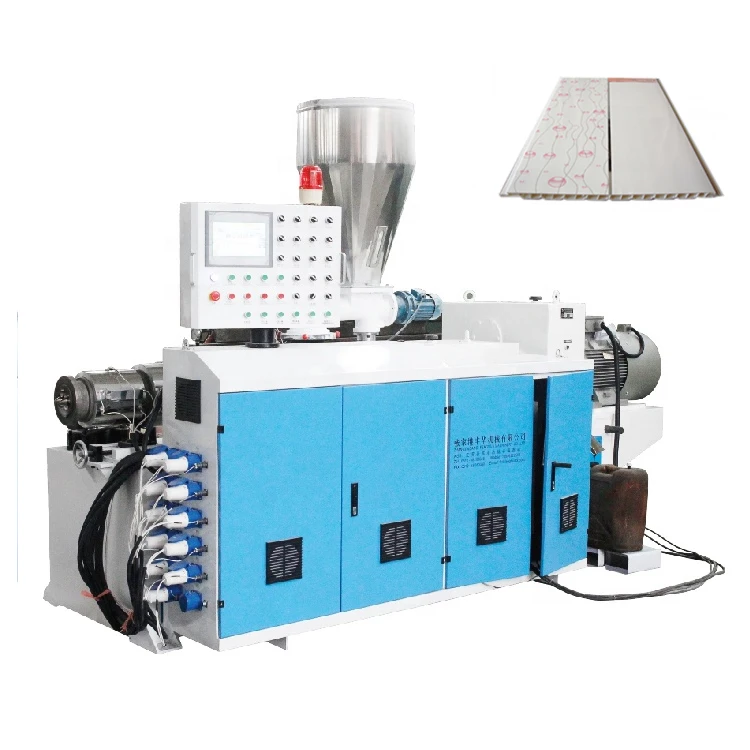

PVC Ceiling Making Machine / PVC Wall Panel Production Line

Description of PVC ceiling and wall panel making machine:

PVC ceiling system products mainly by polyvinyl chloride resin, a certain amount of anti-aging agent, modifier additives, by extrusion,calendering,vacuum forming and others to process.

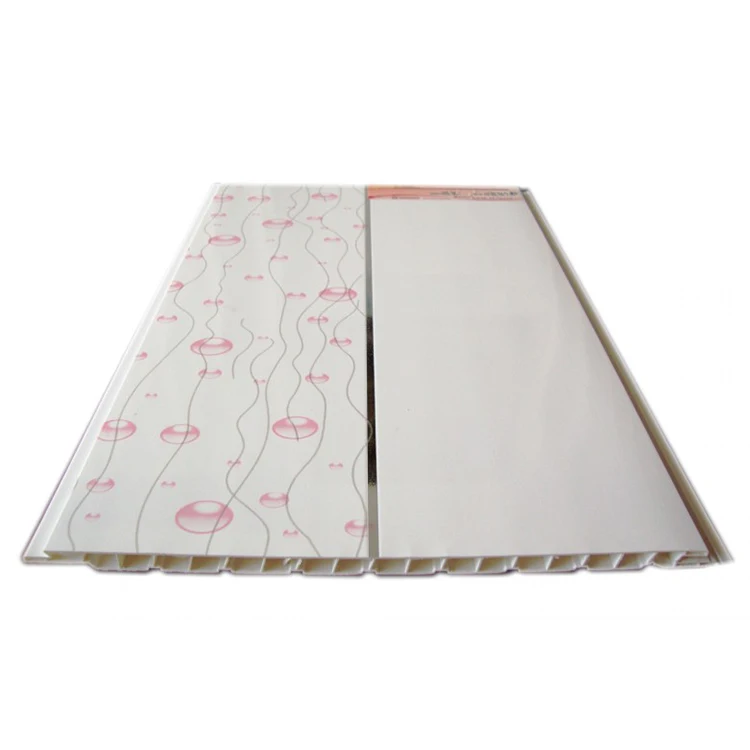

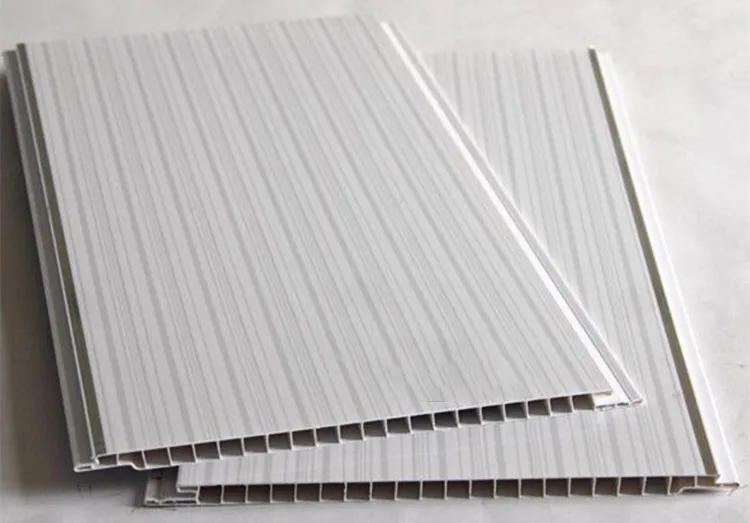

PVC laminated ceiling profile making machine is used to produce PVC ceiling, PVC wall panel with width from 108mm to 900mm,such as 180mm,200mm,250mm,300mm with different section shape and height thickness. The surface of PVC ceiling can be treated by double color printing & coated with glossy oil, or by heat transfer printing, or by film lamination, which can make marble, wooden design on surface of product.

If change the mould, it can produce other different PVC profiles, such as pvc wall panel, pvc trunking , pvc window sil plate, pvc angle line, etc.

Main Features of PVC ceiling and wall panel making machine:

1.speed controlled by inverter, saving power and easy to adjust speed;

2.extruder temperature controlled by Omron intelligent controller, temperature fluctuation self adjusting;

3.low power consumption: lowest total production line consumption, economical price, suitable for large scale investment.

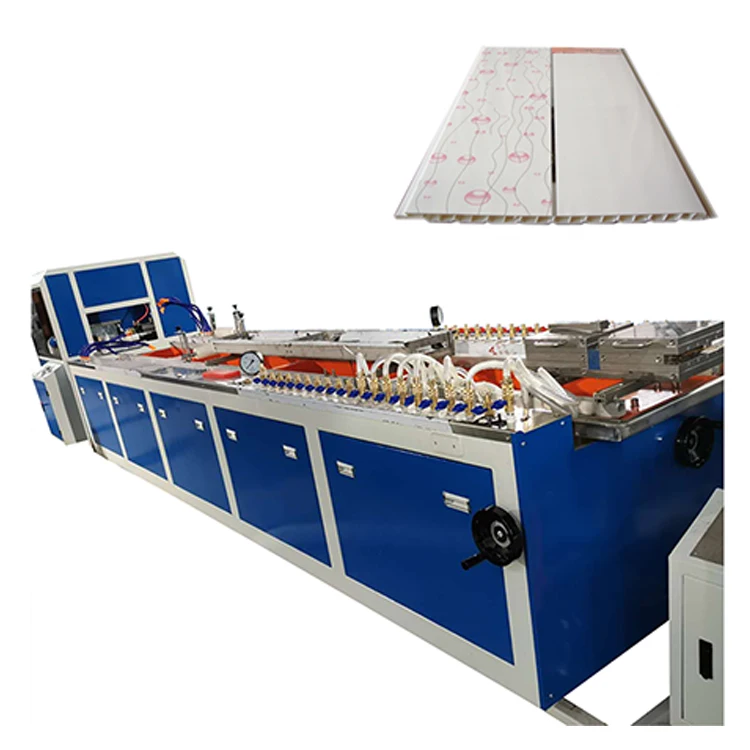

Process flow of PVC ceiling and wall panel production line:

PVC powder + other addictive → Mixer mixing → Double-screw extruder → Die & mould → Vacuum calibration platform → Haul-off machine → Film laminator / Heat transfer machine→ Cutter →Stacker

Application of PVC ceiling and wall panel:

PVC ceiling system products are widely used in household ornament, public management place, office, such as the kitchen, the bathroom's ceiling decoration, etc.

Main Technical Parameter:

Q1: Why choose us?

Q1: Why choose us?

A: Sunlins International Trade Co., Ltd. is specialized for the products with long time experience. We alwayspay attention to the quality of equipment we manufactured, and we have sufficient team

which can go to customer factory in very short time when it's required. And so far we have

installed machines at most hot spot region around the world, the stable running of machines are the best explanation. Welcome contact us to know reference customer near to

Q2: How long the machine can be delivered?

A: Generally we have the semi-ready machines or even ready machine at store, so the deliv-

ery time is very fast, normally around 30 40days,depending on the kinds of machines and

the quality of machines you will order.

Q3: How to install the machines?

A: Upon customer's requirement,we can send technician to customer's factory for installation

and training. So the Chinese technician will install machines, teach local workers about

machine installation and operations and so on.

Q4: What kind payment terms?

A: We can accept multiple kind payment terms,like T/T, LC,ETC.

Q5: What's the warranty?

A: One year since installation completed. In the warranty period, in case any parts broken by

uncontrolled factor, we will be responsible and send the parts immediately by courier or air

cargo.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices