Roll up Shutter Door Cold Roll Forming Machine Rolling Steel Roller Shutter Door Slat Forming Machine

- Category: >>>

- Supplier: Henan Dingkou Industrial Co. Ltd.Henan Ltd.

Share on (1601034599128):

Product Overview

Description

Product information

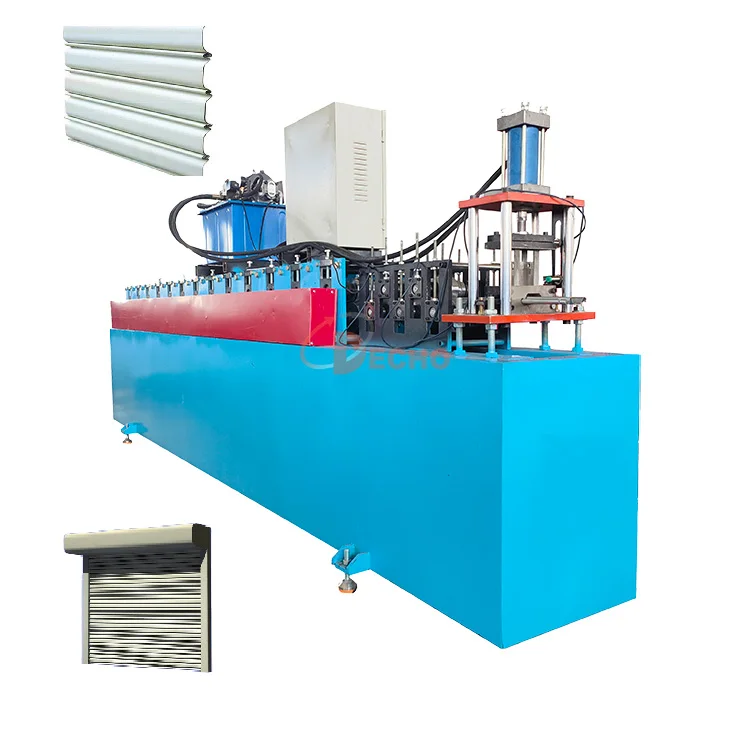

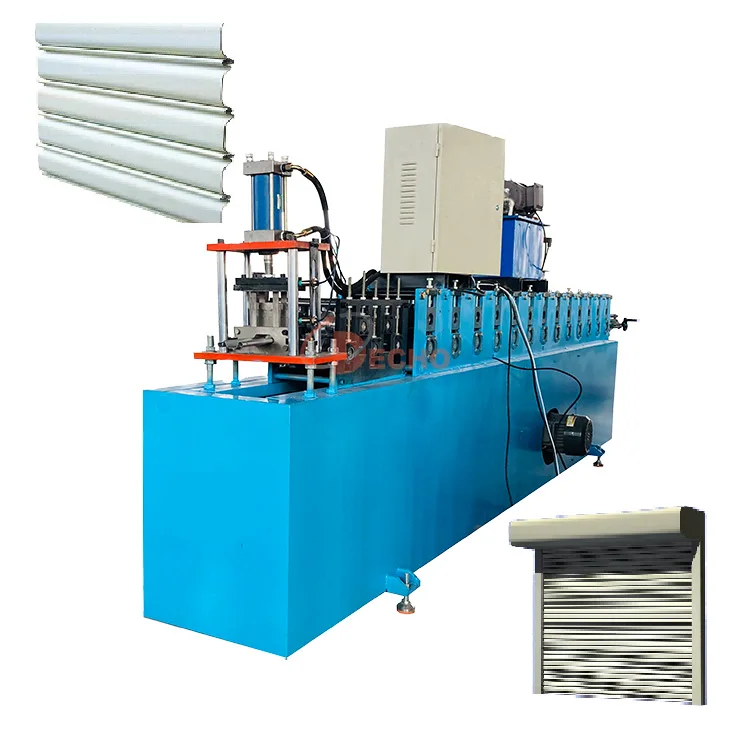

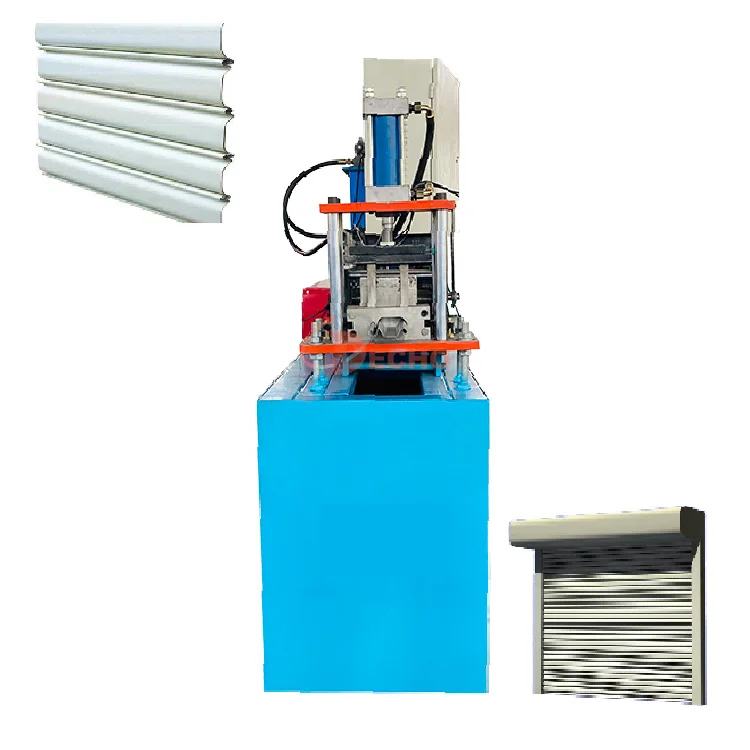

1.Product Image

Shutter door roll forming machine has been designed to produce horizontal roller shutter door slats out of galvanized or prepainted steel strips.(Customized according to customer configuration requirements.)

2.Typical door slats type drawings

As the manufacturer of the roll forming machinery, we can produce most of the products according to your requirements, not just the size of the products on this page.

3. Work Flow

Capacity of the entire production line is 10-20m/min. It consists of 5 parts. Un-coiler→Feeding material →Roll forming→ Auto cutting→ Products receiving table, but It only takes 1-2 worker.

4. Equipment List

NUM | Equipment Name | Quantity |

1 | Uncoiling Device | 1set |

2 | Forming Main Machine | 1 set |

3 | Hydraulic Cutting System | 1 set |

4 | Material Receiving Table | 1 set |

5 | PLC Control System | 1 set |

6 | Supporting Accessories | 1 set |

5. Product Specification

Item | Parts | Specification & Description |

1.Raw Material | Type | GI / GL /PPGI / PPGL /Customization |

Thickness(mm) | Typically ranging from 0.6 to 1.2. Can customize according to customer needs. | |

2.Un-coiler Device | Type | Default manual uncoiler, optional electric uncoiler or hydraulic uncoiler. |

Bearing(Tons) | 3T/5T | |

Way of working | Manual / Electric / hydraulic tensioning crank. The center of the four-bar linkage is supported outward. | |

Panel Width(mm) | Typically ranging from 100 to 200. Can customize according to customer needs. | |

Coil Inner diameter | φ480-500mm | |

Inner contraction range | φ450-550mm | |

3.Forming Main Machine | Main frame | Material:Galvanized steel square tube, section size:80×80(mm). Material wall thickness:3mm Processing:Welding box frame |

Material:45#steel Thickness:14mm Processing :laser cutting | ||

Material : 45# steel with chrome 0.05mm Diameter:60-70mm Processing : Precision machining, heat treatment, precision grinding | ||

Rollers | Material: 45# steel Chrome Plated or Gcr15(Raw material thickness>0.8mm) Processing:Quenching, precision turning, polishing treatment | |

Roller Station | 12-14 stations or Customization | |

Specifications:1 inch chain wheel with gear transmission Processing :Quenching heat treatment Gear oil:18 # hyperbolic gear oil | ||

Power:4KW Brand:Lichao(optional) Reducer: Cycloidal reducer Protection level:IP55 Explosion-proof level:ExdIICT4 | ||

Type | Automatic Hydraulic Cutting | |

Blade material | Cr12MOV heat treatment process | |

Pump | hydraulic pressure:10-12mpa Hydraulic oil: 46# | |

Pump motor for cutter | Power:3KW | |

5.Receiving rack | Type | Manual receiving rack |

Plc brand:Delta(optional) Text control box:Vertical LCD touch screen control box Language: English / Chinese / Customized | ||

Inverter | Rated power:5.5KW |

6. Product details

Un-coiler

Usage: Used to support steel coils, and uncoil and straighten the coil into the feeding port.

Steel coil width : 100-200 mm. (According to your actual drawing)

Loading capacity: 3T/5T

Loading capacity: 3T/5T

Inner diameter: 450-550mm

Feeding port

Usage: Applied to control the width and position of the steel sheet,which is guided into the correct position of machine to make sure the panel is neat and parallel.

Other Accessorie: The hand knife can cut the raw materials and control the length of the feed, thereby saving raw materials.

Other Accessorie: The hand knife can cut the raw materials and control the length of the feed, thereby saving raw materials.

Roll forming system

Shaft material: 45#Steel Chrome Plated.

Roller material: Default 45#Steel Chrome Plated, optional GCr15.

Roller material: Default 45#Steel Chrome Plated, optional GCr15.

Characteristic: After being forged, polished, heat-treated and finally

chromeplated.

Auto cutting system

Blade material:Default Cr12mov, optional SKD11.

Characteristic: Quenching before heat treatment can ensure the smoothness and hardness of the surface.

Cutting method: Hydraulic cutting (stable cutting with high speed and low noise)

PLC control system

Usage:Control the length, quantity, speed, accuracy, and other parameters of the product through programming settings.

Language:English, Chinese, or customization. It is easy to operate and use.

Language:English, Chinese, or customization. It is easy to operate and use.

Receiving table

Usage: It adopts welded steel and supported roller to transmit the products, which is used to collect the finished products.

Packaging & Shipping

Packaging Details

1. One container (20ft or 40ft ) for loading one set machine with manual decoiler and receiving rack.

2. The whole wiped Anti Rust Oil, PLC controller covered by foam film.

3. Spare parts and some small parts packed in plastic tooling box.

2. The whole wiped Anti Rust Oil, PLC controller covered by foam film.

3. Spare parts and some small parts packed in plastic tooling box.

Related Products

About Us

1.Company profile

Decho offers a wide range of products and good solutions for companies operating in construction, manufacturing industries. Our products include: Roofing forming machine / Purlin forming machine / Light steel keel forming machine / Storage Rack System forming machine / Floor decking forming machine / Shutter door forming machine /Highway Guardrall forming machine / Solar Panel Bracket forming machine / Truss roll forming machine / Channel roll forming machine / Ceiling roll forming machine / Slitter & cutter machine / Leveling & cutting machine / Bending machine / Decoiler (uncoiler).

2. Certificate

3. Customer case

Project in Thailand

Project in India

Project in Russia

FAQ

1. What is the production speed of your machine?

We can produce machines with a speed of 1-60m/min. Customers usually choose machines with a speed of 10-20m/min. We can customize according to your needs.2. How long is the warranty period for this machine?

The service life of the solenoid valve is 3 years, and the rollers are replaced for free during the service life. The warranty period of the entire machine is 2 years.

3. Why purchase from us instead of from other suppliers?

We offer machines with higher cost-effectiveness, ensuring on-time delivery, longer warranty periods,and providing after-sales installation services, including online and local installation.

4. How do i pay for my purchase order?

T/T, L/C at sight, Western Union, MoneyGram.

5. What is the lifespan of this machine?

Usually 15 to 20 years.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices