Ultrasonic Gold Wire Ball Bonding soldering Machine low power laser devices and other semiconductor internal lead welding

- Category: >>>

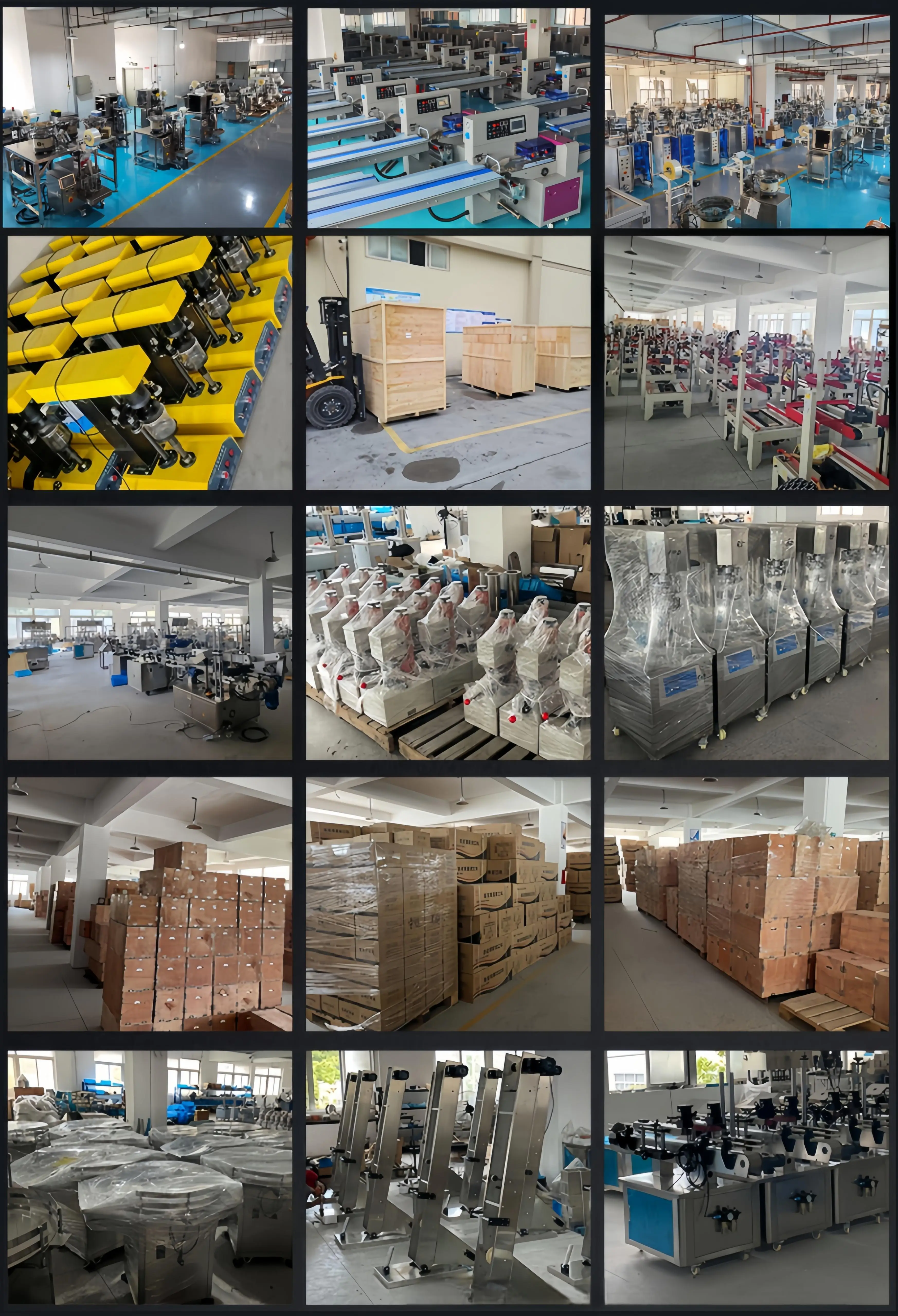

- Supplier: Dongguan Tes Machinery Co . Ltd.

Share on (1601092704145):

Product Overview

Description

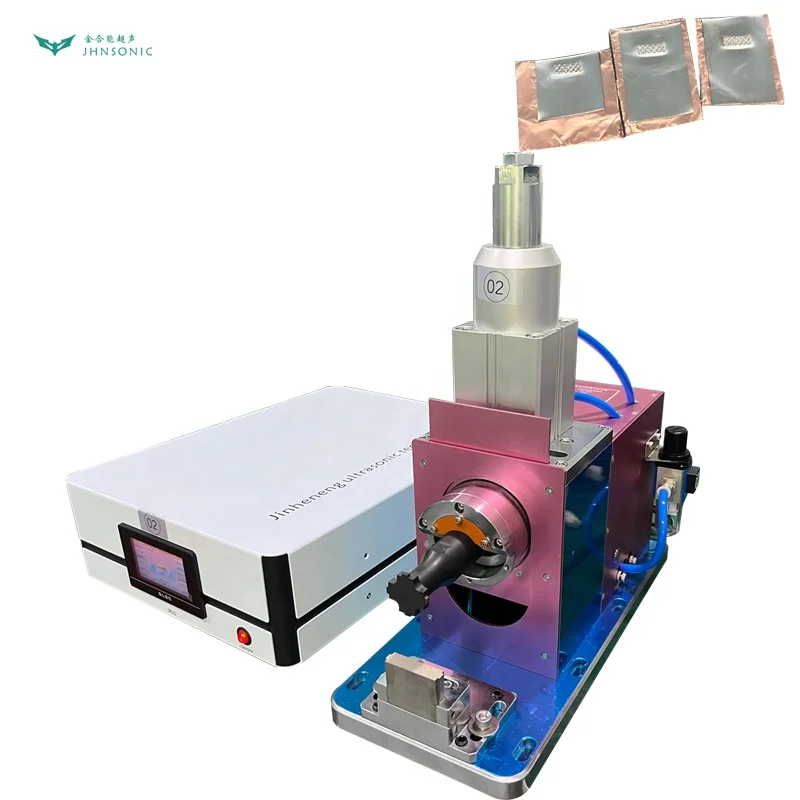

TES SH2012 Ultrasonic Gold Wire Ball Bonding Machine

Key attributes

Other attributes

Weight (KG)

30

Showroom Location

None

Video outgoing-inspection

Provided

Machinery Test Report

Provided

Marketing Type

Hot Product 2024

Warranty of core components

1 Year

Core Components

PLC

Place of Origin

Guangdong, China

Warranty

1 Year

Condition

New

Brand Name

TES

Model Number

TES-SH2012

Packaging and delivery

Packaging Details

PLYWOOD BOX+FOAM

Selling Units:

Single item

Single package size:

52*46*55 cm

Single gross weight:

30.000 kg

The ultimate version of manual wire bonding machine, high power, patch, small power, laser devices and other semiconductor internal lead welding can be welded, only need to replace the fixed fixture, one machine is multi-purpose, value for money!

Product Name: SH2012 Gold Wire Ball Bonding Machine (Ultrasonic Gold Wire Ball Bonding Machine)

Product Description: Stable performance, easy to operate, cost-effective, compact body, very suitable for laboratory use of a small desktop machine.

Product use

Gold ball bonding machine is mainly used for welding the inner leads of high-power light emitting diodes (LED), laser tubes (lasers), small and medium-sized power diodes, triodes, integrated circuits, sensors and some special semiconductor devices, especially for welding high-power light emitting tubes.

Welding principle:

This machine utilizes the ultrasonic wave friction principle to realize the different medium surface welding, is one kind of physical change process. First, the gold wire head end must pass through the processing to form the spherical shape (this machine uses the negative electron high pressure to form the ball), and carries on the preheating treatment to the welding metal surface first (does not heat also to be able to weld, looks at the sample request whether needs the heating treatment); Under the combined action of time and pressure, gold wire ball produces new deformation on the metal welding surface, which makes the two media reach reliable contact, and through ultrasonic friction vibration, metal bonds are formed between two metal atoms under the action of atomic affinity, thus realizing the welding of gold wire lead. Gold wire ball welding is superior to silicon-aluminum wire welding in electrical properties and environmental applications.

Product features:

1. One-way welding can remember the data of two lines, which is convenient for left and right brackets to adopt one-way welding on the same side.

2. In bidirectional welding, after welding the first line, it automatically runs above the first welding of the second line, roughly aligning with the first welding spot of the second line, which can improve efficiency and protect the first arc.

3. In bidirectional welding, the height of two lines and the height of arch wire can be adjusted respectively, which is beneficial to the welding of brackets with different height of two welding.

4. Radian heightening function, there are three schemes: Arc 1, Arc 2 and Arc 3, which can achieve any arc you want. For high-power pipe brackets, deep cup brackets and piranha brackets with high radian requirements, the qualified rate will be greatly improved.

5. The function of repairing balls in the second welding can greatly improve the weldability of the second welding and reduce the dead point rate.

6. One-step or two-step selection of automatic film passing. For brackets with large distances such as Φ 8 mm and 10mm, selecting two-step film passing at a time will greatly improve the production efficiency.

7. Continuous film passing function can improve efficiency for reworking bracket.

8. The cleaver detection function can detect whether the cleaver is correctly installed, greatly reducing artificial virtual welding.

9. Four ultrasonic power outputs can ensure that the two welding joints of the two edges are basically the same as far as possible. At the same time, because the parameters of the welding joints on the wafer bracket are different, choosing different welding powers on the wafer and the bracket can ensure that the welding joints on the wafer and the patch ball and the first welding on the bracket meet the requirements.

10. Ball sintering performance is greatly improved, and smaller primary welding (ball welding) and more reliable secondary welding can be obtained.

Product Name: SH2012 Gold Wire Ball Bonding Machine (Ultrasonic Gold Wire Ball Bonding Machine)

Product Description: Stable performance, easy to operate, cost-effective, compact body, very suitable for laboratory use of a small desktop machine.

Product use

Gold ball bonding machine is mainly used for welding the inner leads of high-power light emitting diodes (LED), laser tubes (lasers), small and medium-sized power diodes, triodes, integrated circuits, sensors and some special semiconductor devices, especially for welding high-power light emitting tubes.

Welding principle:

This machine utilizes the ultrasonic wave friction principle to realize the different medium surface welding, is one kind of physical change process. First, the gold wire head end must pass through the processing to form the spherical shape (this machine uses the negative electron high pressure to form the ball), and carries on the preheating treatment to the welding metal surface first (does not heat also to be able to weld, looks at the sample request whether needs the heating treatment); Under the combined action of time and pressure, gold wire ball produces new deformation on the metal welding surface, which makes the two media reach reliable contact, and through ultrasonic friction vibration, metal bonds are formed between two metal atoms under the action of atomic affinity, thus realizing the welding of gold wire lead. Gold wire ball welding is superior to silicon-aluminum wire welding in electrical properties and environmental applications.

Product features:

1. One-way welding can remember the data of two lines, which is convenient for left and right brackets to adopt one-way welding on the same side.

2. In bidirectional welding, after welding the first line, it automatically runs above the first welding of the second line, roughly aligning with the first welding spot of the second line, which can improve efficiency and protect the first arc.

3. In bidirectional welding, the height of two lines and the height of arch wire can be adjusted respectively, which is beneficial to the welding of brackets with different height of two welding.

4. Radian heightening function, there are three schemes: Arc 1, Arc 2 and Arc 3, which can achieve any arc you want. For high-power pipe brackets, deep cup brackets and piranha brackets with high radian requirements, the qualified rate will be greatly improved.

5. The function of repairing balls in the second welding can greatly improve the weldability of the second welding and reduce the dead point rate.

6. One-step or two-step selection of automatic film passing. For brackets with large distances such as Φ 8 mm and 10mm, selecting two-step film passing at a time will greatly improve the production efficiency.

7. Continuous film passing function can improve efficiency for reworking bracket.

8. The cleaver detection function can detect whether the cleaver is correctly installed, greatly reducing artificial virtual welding.

9. Four ultrasonic power outputs can ensure that the two welding joints of the two edges are basically the same as far as possible. At the same time, because the parameters of the welding joints on the wafer bracket are different, choosing different welding powers on the wafer and the bracket can ensure that the welding joints on the wafer and the patch ball and the first welding on the bracket meet the requirements.

10. Ball sintering performance is greatly improved, and smaller primary welding (ball welding) and more reliable secondary welding can be obtained.

We Recommend

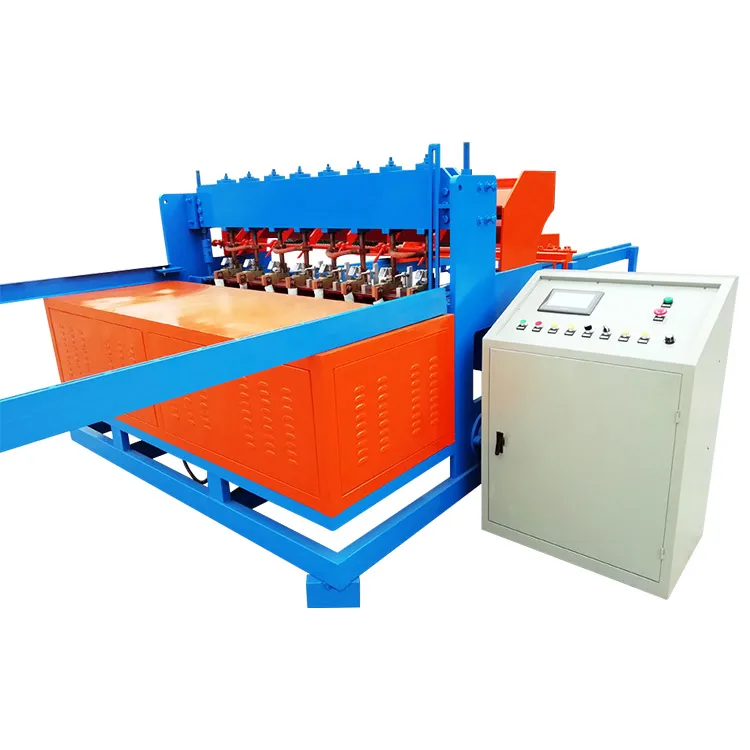

Fully Automatic Welding Galvanized Wire Mesh Machine for Making Welded Wire Mesh

$15,000.00-17,000.00

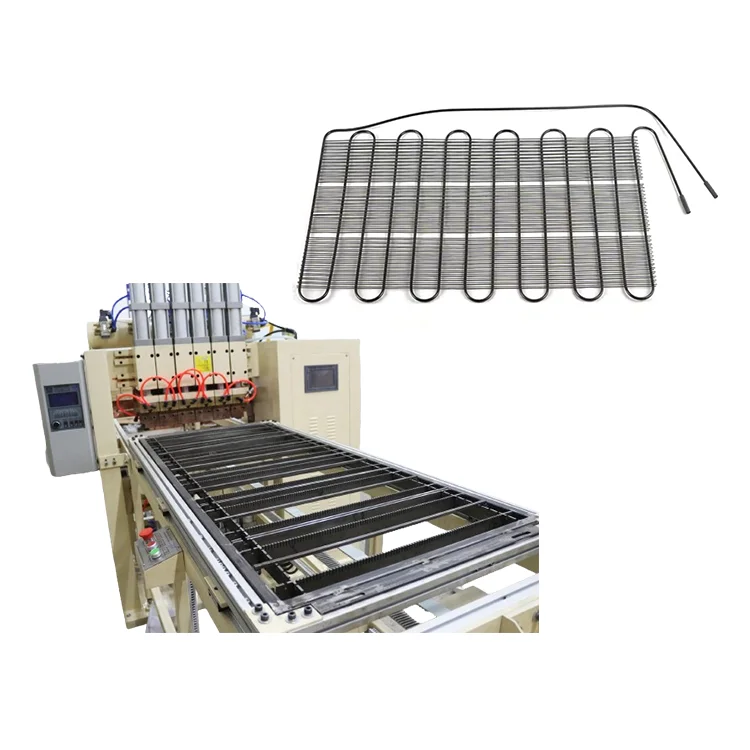

Gantry Type Wire on Tube Condenser Automatic Welding Making Machine

$32,000.00-33,680.00

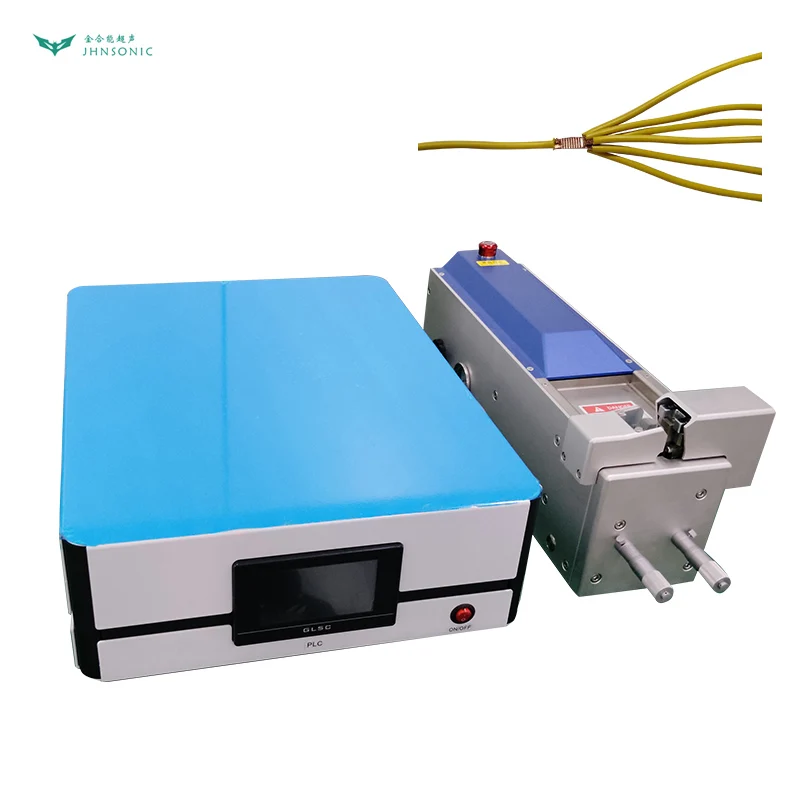

High Quality Pouch Cell Tab CNC Ultrasonic Metal Spot Welder Welding Machine

$6,800.00-7,000.00

New Arrivals

New products from manufacturers at wholesale prices