Ultrasonic thick aluminum wire bonding soldering machine semiconductor devices laboratory uses wire bonder

- Category: >>>

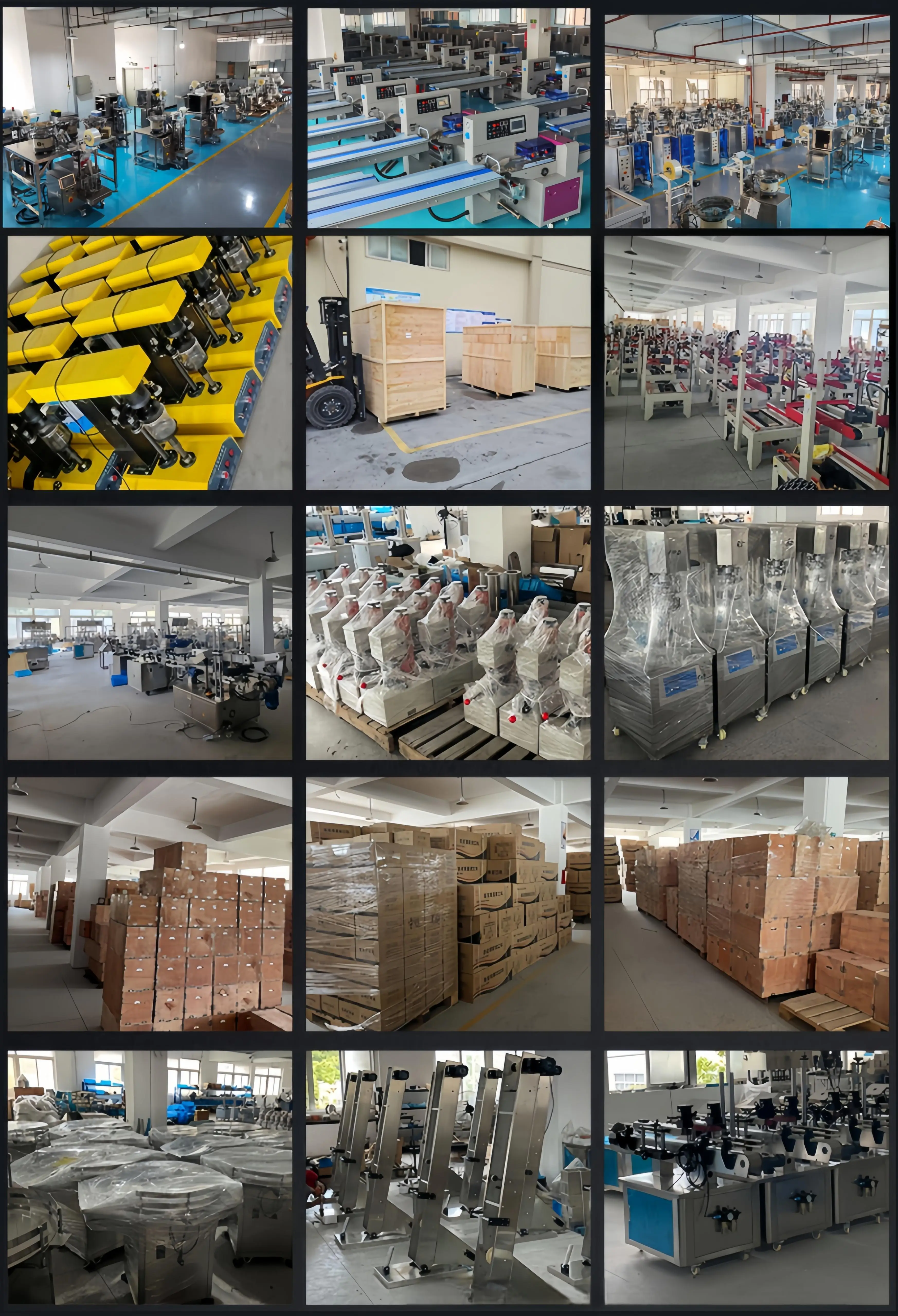

- Supplier: Dongguan Tes Machinery Co . Ltd.Dongguan Ltd.

Share on (1601098463384):

Product Overview

Description

TES SH3018 Ultrasonic thick aluminum wire bonding machine semiconductor devices laboratory uses wire bonder

Key attributes

Other attributes

Weight (KG)

45

Showroom Location

None

Video outgoing-inspection

Provided

Machinery Test Report

Provided

Marketing Type

Hot Product 2024

Warranty of core components

1 Year

Core Components

PLC

Place of Origin

Guangdong, China

Warranty

1 Year

Condition

New

Brand Name

TES

Model Number

TES-SH3018

Packaging and delivery

Packaging Details

PLYWOOD BOX+FOAM

Selling Units:

Single item

Single package size:

620×610×560mm

Single gross weight:

50.000 kg

Product description:

I. Main Uses:

Large and medium power triodes and field effect transistors; Various power modules; High current fast recovery diode, Schottky triode, thyristor; IGBT; Internal lead welding of the above devices and special semiconductor power devices (TO-3, TO-3P, TO-3PF, TO-3PN, TO-3PL, TO-220F, TO-126, TO-12F, TO-66, TO-251, TO-202), automobile sensors and high-power pressure sensors.

Stable performance, easy operation, high cost performance, compact body, very suitable for a small desktop machine used in the laboratory.

II. Characteristics:

1. The motion of welding head in Y and Z directions is driven by stepping motor controlled by computer, precision screw and navigation drive, which is flexible in action, accurate in positioning and fast in speed (about 500-1300 tubes per hour for devices with two lines)

2. Ultrasonic power surplus is large, at the same time, the brand-new transducer design works stably and reliably under the condition of high power and long time, and has the function of cleaver installation detection, which is convenient to judge whether the cleaver is correctly installed. Because the transducer is the core component of this machine, its stable work and the correct installation of cleaver directly affect the weldability and the quality of solder joints.

3. The pressure is produced by electromagnetism, and the original pressure automatic control technology is adopted, which is not only convenient to adjust, but also stable and accurate in the whole welding process, which plays an important role in ensuring the consistency of solder joints.

4. Ultrasonic, pressure and motion system with excellent performance, combined with the cleaver designed by our company and manufactured by American company, makes the solder joint firm, the solder joint shape and arc shape bright, adjustable and consistent, which is completely comparable to automata.

5. It is equipped with the function of one solder and two solder joints, which greatly reduces the resistance of solder joints and improves the reliability when soldering power devices with large chip area (such as thyristors, power modules, etc.).

6. It can memorize the data of span, radian and aiming point height of two lines, and improve the operation speed when welding power devices (such as triode, MOS tube, thyristor, fast recovery and Schottky diode) of two lines.

7. It is easy to adjust. Various parameters (ultrasonic power, time, pressure, radian, span, aiming point height, tail wire, etc.) are placed on the panel and adjusted by switches and knobs.

8. With the various fixtures obtained by our company, it can adapt to the production of semiconductor devices in various packaging forms (such as TO-3, TO-3P, TO-3PF, TO-3PN, TO-3PL, TO-220, TO-220F, TO-126, TO-66, TO-251, TO-202, etc.).

9. This machine can also weld aluminum strip, gold strip, copper wire and other metal wires.

Large and medium power triodes and field effect transistors; Various power modules; High current fast recovery diode, Schottky triode, thyristor; IGBT; Internal lead welding of the above devices and special semiconductor power devices (TO-3, TO-3P, TO-3PF, TO-3PN, TO-3PL, TO-220F, TO-126, TO-12F, TO-66, TO-251, TO-202), automobile sensors and high-power pressure sensors.

Stable performance, easy operation, high cost performance, compact body, very suitable for a small desktop machine used in the laboratory.

II. Characteristics:

1. The motion of welding head in Y and Z directions is driven by stepping motor controlled by computer, precision screw and navigation drive, which is flexible in action, accurate in positioning and fast in speed (about 500-1300 tubes per hour for devices with two lines)

2. Ultrasonic power surplus is large, at the same time, the brand-new transducer design works stably and reliably under the condition of high power and long time, and has the function of cleaver installation detection, which is convenient to judge whether the cleaver is correctly installed. Because the transducer is the core component of this machine, its stable work and the correct installation of cleaver directly affect the weldability and the quality of solder joints.

3. The pressure is produced by electromagnetism, and the original pressure automatic control technology is adopted, which is not only convenient to adjust, but also stable and accurate in the whole welding process, which plays an important role in ensuring the consistency of solder joints.

4. Ultrasonic, pressure and motion system with excellent performance, combined with the cleaver designed by our company and manufactured by American company, makes the solder joint firm, the solder joint shape and arc shape bright, adjustable and consistent, which is completely comparable to automata.

5. It is equipped with the function of one solder and two solder joints, which greatly reduces the resistance of solder joints and improves the reliability when soldering power devices with large chip area (such as thyristors, power modules, etc.).

6. It can memorize the data of span, radian and aiming point height of two lines, and improve the operation speed when welding power devices (such as triode, MOS tube, thyristor, fast recovery and Schottky diode) of two lines.

7. It is easy to adjust. Various parameters (ultrasonic power, time, pressure, radian, span, aiming point height, tail wire, etc.) are placed on the panel and adjusted by switches and knobs.

8. With the various fixtures obtained by our company, it can adapt to the production of semiconductor devices in various packaging forms (such as TO-3, TO-3P, TO-3PF, TO-3PN, TO-3PL, TO-220, TO-220F, TO-126, TO-66, TO-251, TO-202, etc.).

9. This machine can also weld aluminum strip, gold strip, copper wire and other metal wires.

We Recommend

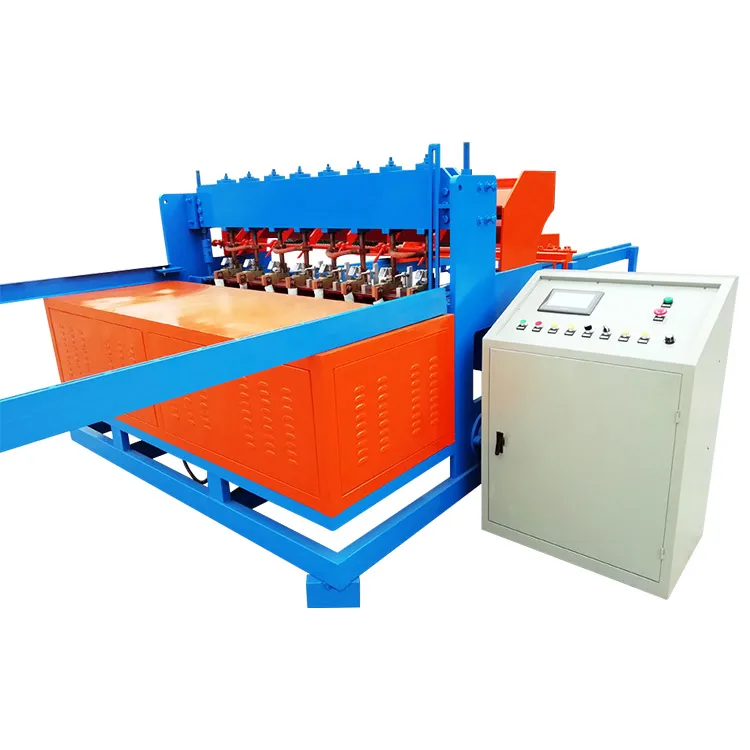

Fully Automatic Welding Galvanized Wire Mesh Machine for Making Welded Wire Mesh

$15,000.00-17,000.00

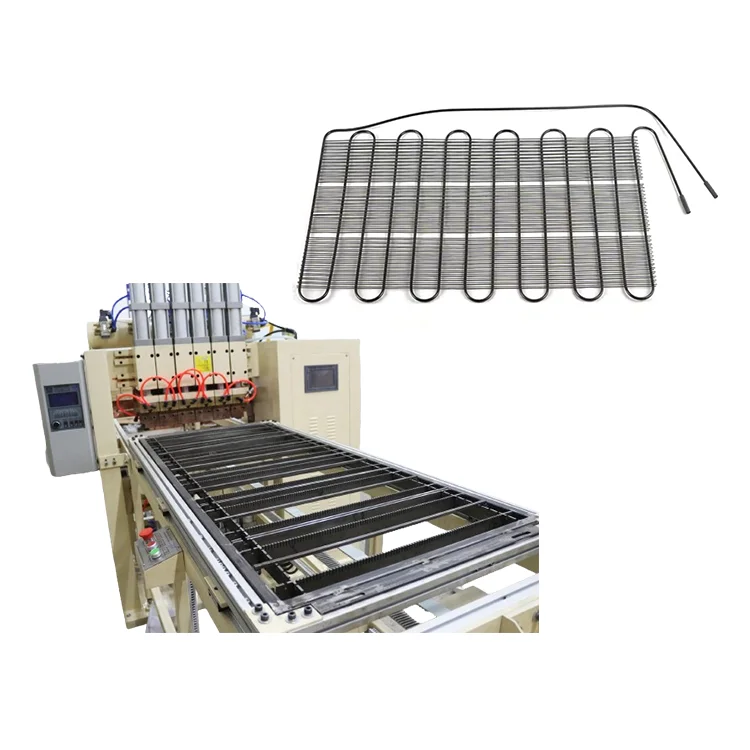

Gantry Type Wire on Tube Condenser Automatic Welding Making Machine

$32,000.00-33,680.00

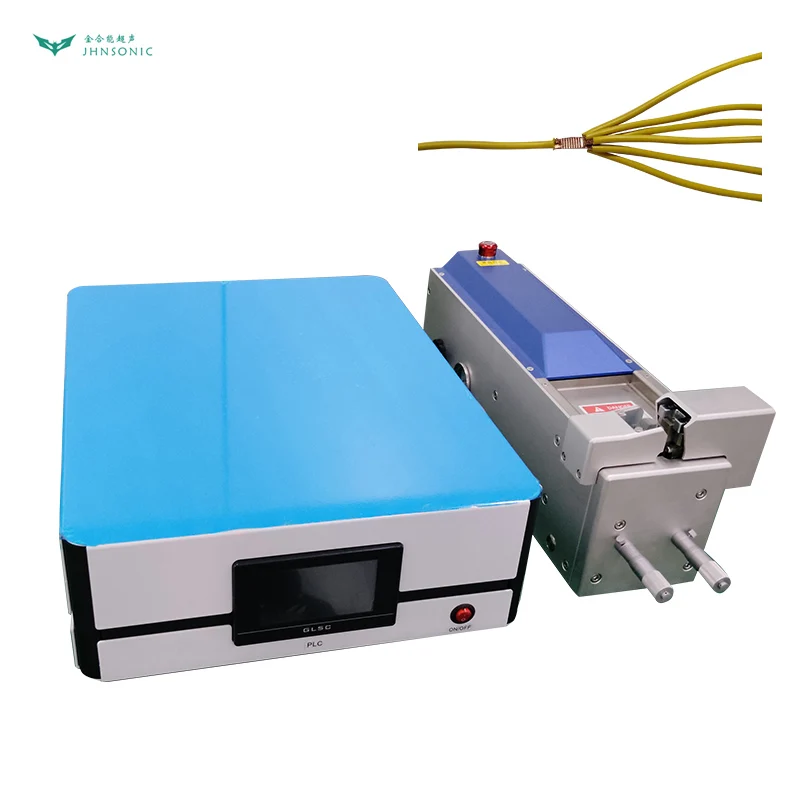

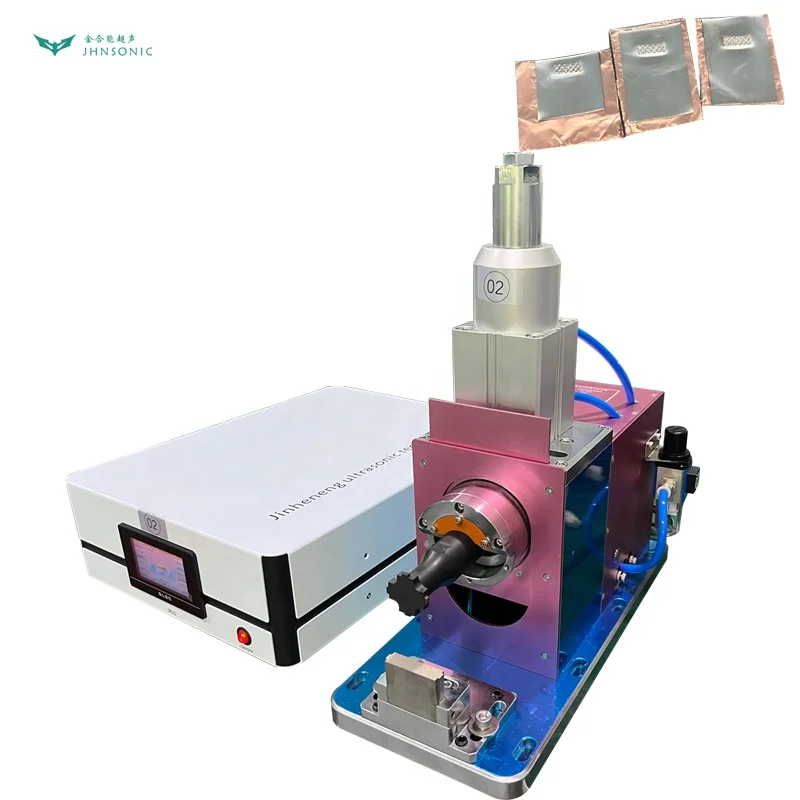

High Quality Pouch Cell Tab CNC Ultrasonic Metal Spot Welder Welding Machine

$6,800.00-7,000.00

New Arrivals

New products from manufacturers at wholesale prices