Custom High Gloss Quick Drying Sheet fed Offset Printing Ink Fluorescent ink for packaging printing

- Category: >>>

- Supplier: Guangzhou Bluewings Technology Co. Ltd.Guangzhou Ltd.

Share on (1601237881403):

Product Overview

Description

Product Description

Custom High Gloss Quick Drying Sheet-fed Offset Printing Ink Fluorescent ink for packaging printing

Item name.: | Fluorescent ink | ||||||

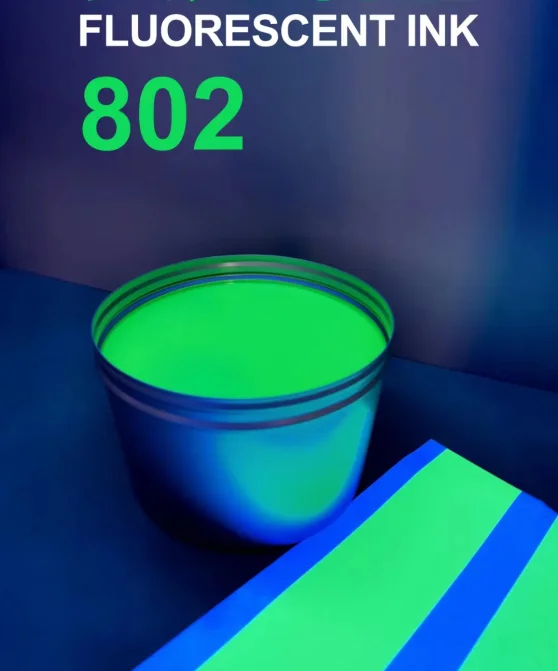

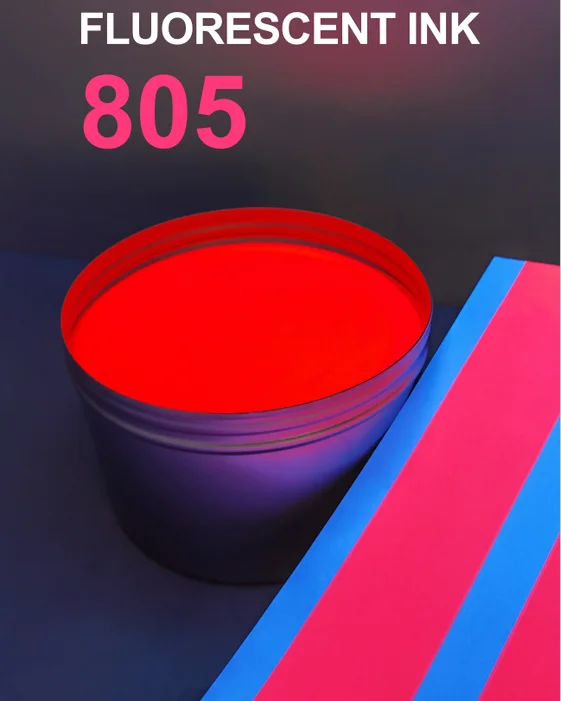

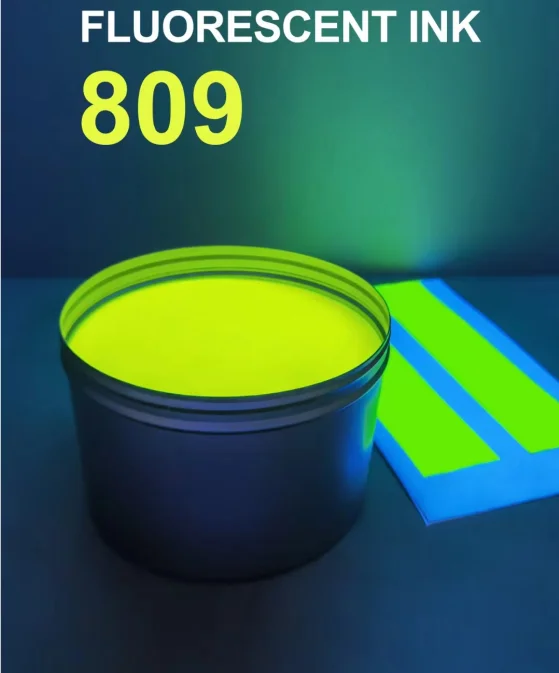

Colour: | 801#,802#,803#,804#,805#,806#,806#,807#809# | ||||||

Packing: | 1kg/tin | ||||||

MOQ: | 2kg | ||||||

Perfecting vegetable oil-based process inks offer the printer a premium quality ink with high color strength and excellent press performance to meet today’s rigorous printing demands. These inks run on standard presses very successfully but are specifically formulated for the new generation of high speed, multi-unit perfecting presses.

Pressroom Chemicals

Druckmeister® Anti Set-Off Powders speed ink drying by forming a separation between the printed sheets as they leave the press.

They also break the suction effects of wet ink and static and prevent the ink from setting off onto the sheet above. Choose from a complete line of coated and uncoated powders. These powders provide outstanding performance in electronic units and air guns. Suitable for food contact from paper and paperboard packaging.

They also break the suction effects of wet ink and static and prevent the ink from setting off onto the sheet above. Choose from a complete line of coated and uncoated powders. These powders provide outstanding performance in electronic units and air guns. Suitable for food contact from paper and paperboard packaging.

Pressroom Consumables

Druckmeister® offset inks offer a complete range of high quality and versatile range of sheet-fed offset printing inks for use on a wide variety of printing substrates.

Druckmeister® printing inks range of process inks, Pantone® fluorescent and metallic inks are all manufactured in strict accordance with international color standards.

The special constituents of the Druckmeister® inks are matched precisely to the individual stages in the manufacturing process.

The wetting medium and the finely controlled dispersion conditions have been chosen so as to ensure that the ink pigments are coated completely and in a stable manner ensuring improved press stability. Improvements in quality are to be found in areas such as higher color standards.

Druckmeister® inks are ideally suited for use on a wide variety of substrates and demand the highest levels of machine performance and print quality.

Druckmeister® printing inks range of process inks, Pantone® fluorescent and metallic inks are all manufactured in strict accordance with international color standards.

The special constituents of the Druckmeister® inks are matched precisely to the individual stages in the manufacturing process.

The wetting medium and the finely controlled dispersion conditions have been chosen so as to ensure that the ink pigments are coated completely and in a stable manner ensuring improved press stability. Improvements in quality are to be found in areas such as higher color standards.

Druckmeister® inks are ideally suited for use on a wide variety of substrates and demand the highest levels of machine performance and print quality.

Pressroom Chemicals

With the Druckmeister® range of pressroom chemicals we are committed to sharing the goals of every printer, wherever they may be located, whatever the size or type of their business: namely to improve quality, increase productivity, save costs, protect the environment and enhance working conditions.

Pressroom Chemicals

Pressroom Chemicals

Druckmeister® printing plates deliver high quality, accurate color reproduction and reliable performance at affordable prices. Druckmeister® Plate Imaging System is part of a full range of plates and chemistry products designed to increase productivity. All Druckmeister® plate products are manufactured in accordance with ISO 9001/14002 Quality Management System. We offer consistent quality products across the range — from product to product, batch to batch and box to box – resulting in world class products which are both high performing and user-friendly.

Druckmeister® Plate Imaging System Features: Unsurpassed productivity. By dramatically reducing vacuum time and halation, Druckmeister plates maximize productivity in the plate room and pressroom.Rich tone reproduction. The Druckmeister® Plate Imaging System range offers exceptional dot resolution in highlight, mid-tone and shadow areas, with a minimized dot gain ratio and superior print quality Clean work environment. Druckmeister® has produced the cleanest plate system available. Neither plate nor processing solutions are harmful to the environment

Excellent ink and water balance. A unique multigrain aluminum structure provides water receptivity that ensures an easy-to-maintain ink and water balance, plus minimum dot gain on the press.

Druckmeister® Plate Imaging System Features: Unsurpassed productivity. By dramatically reducing vacuum time and halation, Druckmeister plates maximize productivity in the plate room and pressroom.Rich tone reproduction. The Druckmeister® Plate Imaging System range offers exceptional dot resolution in highlight, mid-tone and shadow areas, with a minimized dot gain ratio and superior print quality Clean work environment. Druckmeister® has produced the cleanest plate system available. Neither plate nor processing solutions are harmful to the environment

Excellent ink and water balance. A unique multigrain aluminum structure provides water receptivity that ensures an easy-to-maintain ink and water balance, plus minimum dot gain on the press.

Pressroom Chemicals

Reliable performance of a printing blanket plays an important role to ensure a smooth printing process. You can always rely on Druckmeister®, ensuring you the best product available in the market. Druckmeister® blankets are genuine all-round blanket suitable for sheet-fed and carton printing as well as for metal printing. A special micro-ground surface compound gives outstanding print quality with sharp dot reproduction across a variety of papers,

boards, metals and printing pressures. Due to exceptional ink transfer properties, solid print densities can be achieved with lower ink film thickness between plate and blanket. The main benefits of this feature are reduced dot gain on the print and even dense solids.The micro sphere compressible layer gives excellent smash resistance, thus ensuring an increased blanket life. Outstanding edgecut resistance enables the use with a variety of sheet sizes without the need for a blanket change.

Pressroom Chemicals

boards, metals and printing pressures. Due to exceptional ink transfer properties, solid print densities can be achieved with lower ink film thickness between plate and blanket. The main benefits of this feature are reduced dot gain on the print and even dense solids.The micro sphere compressible layer gives excellent smash resistance, thus ensuring an increased blanket life. Outstanding edgecut resistance enables the use with a variety of sheet sizes without the need for a blanket change.

Pressroom Chemicals

Consumables are an integral component of any printing, packaging and bindery process. The relationship between equipment and consumables has a direct impact on all aspects of quality, performance, reliability and consistency of the printing process and the final printed product. To ensure consistent production results with maximum quality, Druckmeister® has formed an alliance with the leading manufacturers of consumables.

Fair

Manufacture Specification

Company Introduction

Our Druckmeister ink manufacturing facility is one of the largest printing ink manufacturing plants in China. The site covers in excess of 20 acres and we have an annual capacity in excess of 20,000 metric tonnes.

All of our products are produced in accordance with the requirements of ISO 9001 and 14001 certification.

The Group’s backward integration allows us to produce our own pigments, flushed pigments, resins and ink additives to ensure quality and consistency across the whole of the manufacturing process.

Manufacturing Facilities

Inks are produced in-house using 12 tonne three-roll mills. The large batch size ensures quality and consistency. We have storage facilities for over 400 tonnes of ink in storage tanks seamlessly integrated into our ink manufacturing systems.

Ink Manufacture

Currently, we have twelve three-roll mills. This capacity is being expanded. Each mill produces ink in 400 kg batches. We have an annual capacity of 20,000 tonnes of sheet-fed ink.

Flushed Colour Plant

Our pigment-flushing facility is one of the most advanced in China. Using this advanced manufacturing technology, we are able to produce flushed pigments of exceptional quality both for domestic and export markets. Flushed pigments offer benefits of excellent transparency, dispersion and sharpness of colour–characteristics reflected in ourproducts. The pigment flushing plant produces two-tonne batches.

Ink Packing Lines

All our sheet-fed inks are packed on semi-automatic production lines using interconnected computer controlled dosing devices to ensure that the correct weight of ink is packed into each container. Our products can be packed in a variety of different weight containers.

We have recently installed three further lines of semi-automatic vacuum packaging lines which fill either 1 kg or 2.5 kg vacuum packed tins which ensure non-skinning properties during transportation and storage.

Research and Development

We constantly strive to produce new products that will become the benchmark for quality and consistency. Our modern, fully equipped laboratories employ graduate chemists and technicians who understand our customers requirements and ensure our continued technical leadership.

We also employ overseas technical consultants to assist us in our Research and Development of new pigments, resins and ink products.

Quality Control and Quality Assurance

We work according to the requirements of ISO 9001 and ISO 14001 assuring ourselves and our customers of consistent quality and a responsible attitude toward the environmental considerations of our business.

Quality and consistency are our company’s overriding goal.

Staff Development

We run comprehensive in-house training seminars for all our staff to ensure that they are continually improving all aspects of their work.

Lectures and practical training are given by both our senior local staff and invited overseas consultants.

This range of training opportunities covers Research and Development, manufacturing, Quality Control and Quality Assurance, packaging requirements and product use.

Our professional and highly-trained staff are always on hand to ensure that the quality of our products and services are second to none.

All of our products are produced in accordance with the requirements of ISO 9001 and 14001 certification.

The Group’s backward integration allows us to produce our own pigments, flushed pigments, resins and ink additives to ensure quality and consistency across the whole of the manufacturing process.

Manufacturing Facilities

Inks are produced in-house using 12 tonne three-roll mills. The large batch size ensures quality and consistency. We have storage facilities for over 400 tonnes of ink in storage tanks seamlessly integrated into our ink manufacturing systems.

Ink Manufacture

Currently, we have twelve three-roll mills. This capacity is being expanded. Each mill produces ink in 400 kg batches. We have an annual capacity of 20,000 tonnes of sheet-fed ink.

Flushed Colour Plant

Our pigment-flushing facility is one of the most advanced in China. Using this advanced manufacturing technology, we are able to produce flushed pigments of exceptional quality both for domestic and export markets. Flushed pigments offer benefits of excellent transparency, dispersion and sharpness of colour–characteristics reflected in ourproducts. The pigment flushing plant produces two-tonne batches.

Ink Packing Lines

All our sheet-fed inks are packed on semi-automatic production lines using interconnected computer controlled dosing devices to ensure that the correct weight of ink is packed into each container. Our products can be packed in a variety of different weight containers.

We have recently installed three further lines of semi-automatic vacuum packaging lines which fill either 1 kg or 2.5 kg vacuum packed tins which ensure non-skinning properties during transportation and storage.

Research and Development

We constantly strive to produce new products that will become the benchmark for quality and consistency. Our modern, fully equipped laboratories employ graduate chemists and technicians who understand our customers requirements and ensure our continued technical leadership.

We also employ overseas technical consultants to assist us in our Research and Development of new pigments, resins and ink products.

Quality Control and Quality Assurance

We work according to the requirements of ISO 9001 and ISO 14001 assuring ourselves and our customers of consistent quality and a responsible attitude toward the environmental considerations of our business.

Quality and consistency are our company’s overriding goal.

Staff Development

We run comprehensive in-house training seminars for all our staff to ensure that they are continually improving all aspects of their work.

Lectures and practical training are given by both our senior local staff and invited overseas consultants.

This range of training opportunities covers Research and Development, manufacturing, Quality Control and Quality Assurance, packaging requirements and product use.

Our professional and highly-trained staff are always on hand to ensure that the quality of our products and services are second to none.

Nice working environment

Nice working environment

Customer's Feedback

FAQ

1. What is your best price ?

The price is depend on your quantities , If you quantities is big , you can contact me for a discount .

2. I am a reseller and would like to place a big order ,what's the wholesale price?

If you want to resell our products , please contact us for a further discussion , we will give you a wholesale price .

3. The ink shipping is a bit expensive , can i choose another cheaper express ?

Due to the ink is chemical liquid , only Fedex can ship it , about 3-4 workdays will arrived .

4. What is the normal lead time ?

The price is depend on your quantities , If you quantities is big , you can contact me for a discount .

2. I am a reseller and would like to place a big order ,what's the wholesale price?

If you want to resell our products , please contact us for a further discussion , we will give you a wholesale price .

3. The ink shipping is a bit expensive , can i choose another cheaper express ?

Due to the ink is chemical liquid , only Fedex can ship it , about 3-4 workdays will arrived .

4. What is the normal lead time ?

We have our own factory and engineer, will send goods to you about 2-3 workdays after payment confirm .

We Recommend

New Arrivals

New products from manufacturers at wholesale prices