4mm silo silo hot sale new design granary steel plate machine

- Category: >>>

- Supplier: Botou Huayang Roll Forming Machine Co. Ltd.Botou Ltd.

Share on (1601355583908):

Product Overview

Description

Product Description

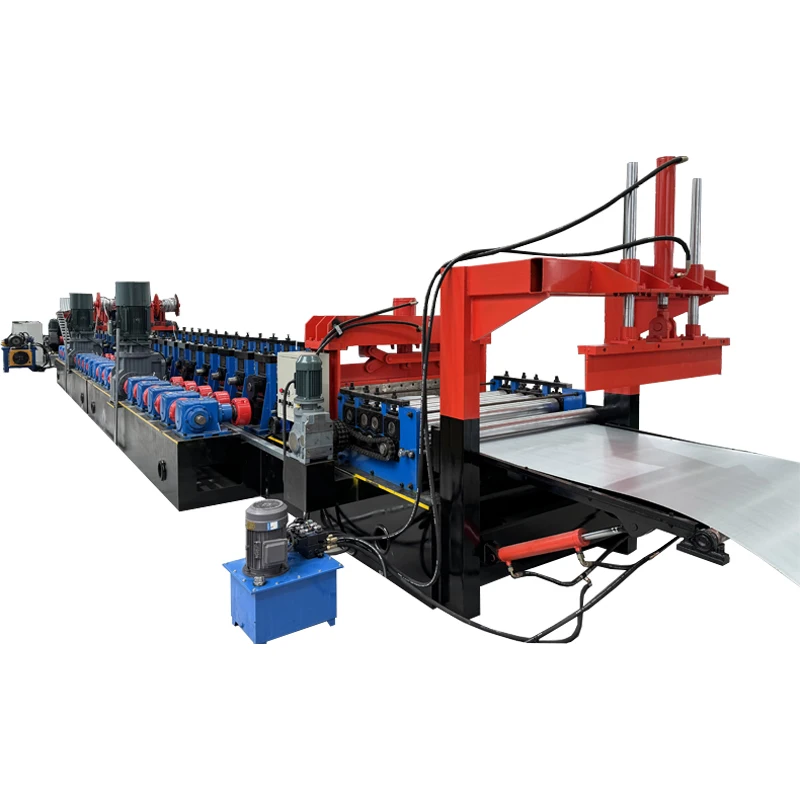

H&Y 4MM Grain Silo Sidewall Sheet Roll Forming Machine

Huayang 4mm grain silo sidewall sheet roll forming machine is a full automatic line include 20ton hydraulic decoil-feeding device -leveling device -hydraulic pre-cutter-roll forming machine -punching device-curving device -cutting device and receive table .the machine is design and produced by our own engineer team ,which is accurate and efficient.

Product Details

NO. | Name | Unit | QTY |

Part 1 | Hydraulic decoiler | set | 1 |

Part 2 | Leveling and feeding device | set | 1 |

Part 3 | Flat sheet cutting device | set | 1 |

Part 4 | Slitting device | set | 1 |

Part 5 | Scrap collector | set | 1 |

Part 6 | Roll forming machine | set | 1 |

Part 7 | Hydrulic punching system | set | 1 |

Part 8 | Curving machine | set | 1 |

Part 9 | Hrdraulic cutting system | set | 1 |

Part 10 | Output table | set | 1 |

10T Hydraulic Decoiler

1.The bearing spindle is made of high strength and fatigue resistant rear wall seamless steel, which is processed by turning,

with strong force and heavy bearing.

2, electrical control, high accuracy, good automation, frequency converter control, arbitrary speed adjustable.

with strong force and heavy bearing.

2, electrical control, high accuracy, good automation, frequency converter control, arbitrary speed adjustable.

Feeding&level&pre-cutter

feeding device can help feeding thicker steel sheet ,the frame can be pressed down .

leveling device can help level the sheet into flat and let it feeding accurately .

pre-cutter can help cut the material when the production finished ,which is more convenient .

Roll Forming Machine

promote the roll forming machine part with gear box driving and two motor ,which has enough strength ,and the basic frame is more strong to support the rollers.

Two sets slitting machine at two side

2.Motor powered scrap collector

2.Motor powered scrap collector

Servo Punching

1. The hydraulic punching mechanism consists of a frame, base, punching mold, hydraulic cylinder and pressing mechanism, servo motor, and precision wire.Composed of rods, guide rails, etc.

2. The CNC punching method summarizes all

punching holes in 34 drawings, including 20+14. Switching hole specifications PLC control System.

2. The CNC punching method summarizes all

punching holes in 34 drawings, including 20+14. Switching hole specifications PLC control System.

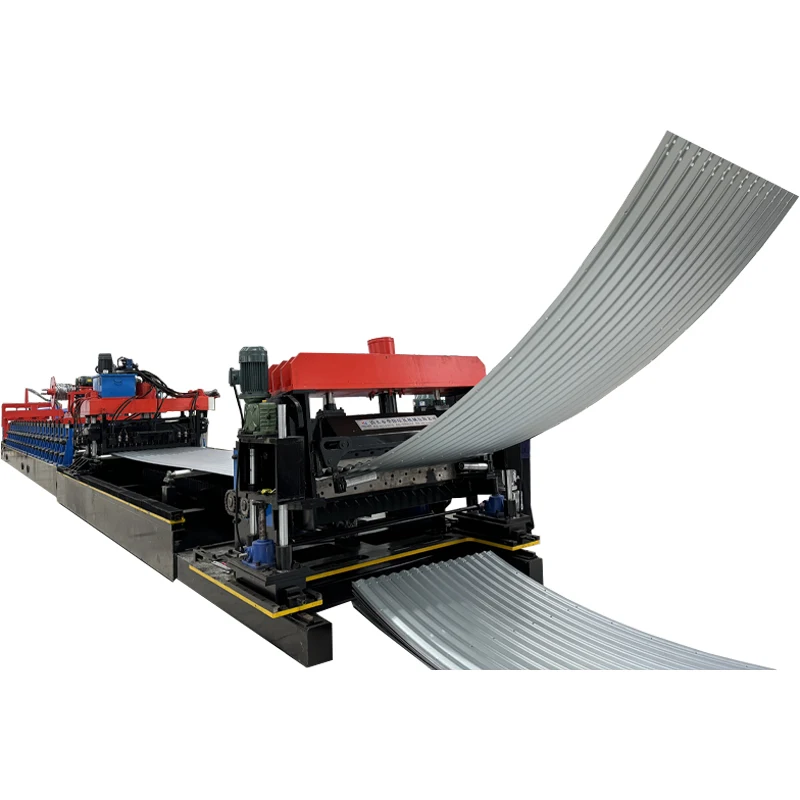

Cutting &curving

The online bending adopts an upward and downward curved structure. The upper roller moves up and down in an arc around the center of rotation, and the adjustment of the upper roller.Controlled precisely by the elevator, adjust the curvature size according to product needs, and the bending direction is

upward. The lower roller revolves around the center of rotation.

upward. The lower roller revolves around the center of rotation.

PLC control system

1. In manual or debugging mode, the control

panel switch can command the computer control system of each component.

2. Xinjie Programmable Logic Controller (PLC)

3. 14 inch PROW-FACE touch screen display

4. Settings screen: Set punching, arching,

cutting and other action programs according to process requirements, set work piece length, and generate production quantity and other data.

panel switch can command the computer control system of each component.

2. Xinjie Programmable Logic Controller (PLC)

3. 14 inch PROW-FACE touch screen display

4. Settings screen: Set punching, arching,

cutting and other action programs according to process requirements, set work piece length, and generate production quantity and other data.

CUSTOMER FEEDBACK

Related Products

we can produce the silo upright forming machine ,silo L frame forming machine ,ladder forming machine ,silo roofing forming machine ,full sets of other forming machines for the silo .also we can produce 0.7-4mm roll forming machine for different purpose.welcome contact to know more !

Our Certifications

Company Profile

Package and Delivery

We Recommend

New Arrivals

New products from manufacturers at wholesale prices