High quality Taiwan vertical machining center VMC850 Taiwan linear guide CNC vertical milling machine

- Category: >>>

- Supplier: Shandong Yijin Cnc Machine Tool Co. Ltd.Shandong Ltd.

Share on (1601356372209):

Product Overview

Description

VMC850 high-precision CNC vertical machining center

VMC850 is a high performance vertical machining center, it has the characteristics of high speed, high performance, high rigidity and high stability. All castings of this machine are secondary tempered to provide excellent rigidity and stability to the machine, which can make this machine maintain high speed and high stability in the process of processing.

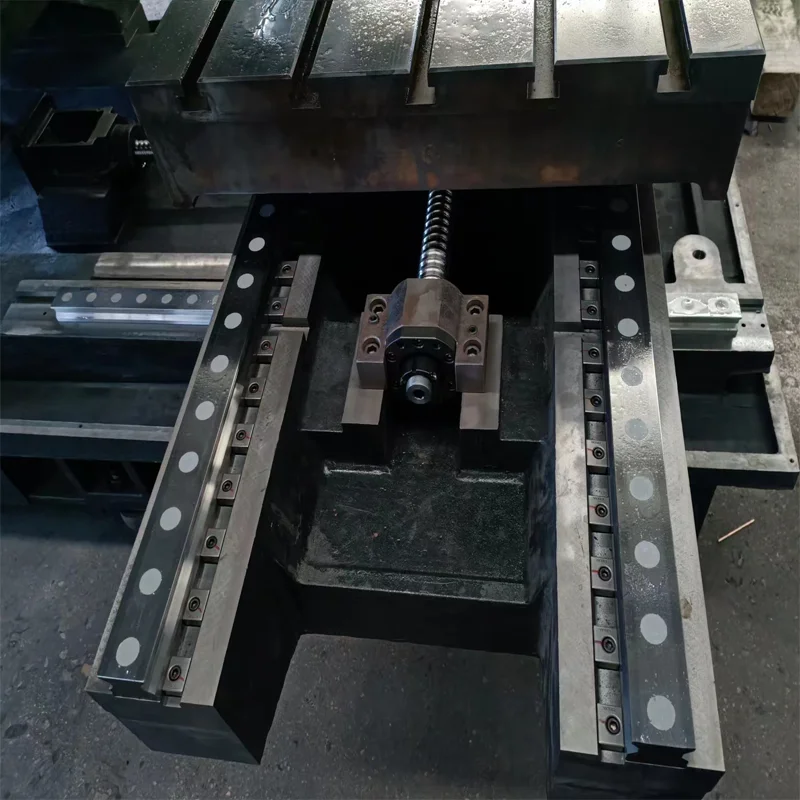

Linear rail

Taiwan HIWIN roller type linear guide rail, with fast spindle and worktable movement speed and high accuracy.

Ball Screw

Taiwan HIWIN C3 ball screw, low noise, high accuracy, and wear-resistant.

TAIWAN SPINDLE

Using Taiwan famous brand high-speed, high-precision, high-rigidity spindle unit, strong axial and radial bearing capacity, speed up to 8000rpm.

OPTICAL MACHINE

lt can be selected according to diff-erent processing requirements.Different Operating Systems.Choose Excellent The system can achieve high accuracy and operation.Convenie-nt and more stable.

Electronic control system

System original driver, using Schneider electrical components

Lubrication System

Positive displacement lubrication pump, intermittent oil supply, automatic lubrication of each part.

Spindel

Adopting a Taiwan spindle, you can choose between an 8000 rpm belt type spindle or a 12000 rpm direct connected spindle, with high

spindle accuracy and low noise

Tool Magazine

Adopting 24 disc type tool libraries ,produced in Taiwan, with a tool change time of only 2.5 seconds, stable tool change, and

high efficiency

Four axis(A axis)

Can choose from bridge deck four axis or chuck type four axis

Five axis(A axis and C axis)

Five axis four linkage or five axis five linkage, the five linkage requires the tool tip to follow

FANUC System

FANUC 0i MF PLUS

Siemens System

Siemens 808D or 828D system

SYNTEC System

SYNTEC 22MA system

Mitsubishi System

Mitsubishi M80 system

KND System

KND 220 M PLUS system

GSK System

GSK 25i system

VMC650 | VMC850 | VMC855 | |

X/Y/Z axis travel (mm) | 900/460/480 | 800/500/500 | 800/550/550 |

Table size (mm) | 1000*420 | 1000*500 | 1000*550 |

Spindle end face to workbench (mm) | 120-600 | 120-620 | 120-670 |

Spindle center to column surface(mm) | 430 | 560 | 540 |

X/Y/Z axis rapid movement(m/min) | 24/24/20 | 24/24/20 | 24/24/20 |

Cutting feed mm/min | 1-10000 | 1-10000 | 1-10000 |

Max load (kg) | 400kg | 500kg | 600kg |

t-slot (mm) | 3-16-90 | 5-18-90 | 5-18-90 |

Spindle diameter(mm) | 120 | 140 | 150 |

Spindle taper | BT40-120 | BT40-140 | BT40-150 |

Main motor power(kw) | 5.5 | 7.5 | 7.5 |

Weight (kg) | 3200 | 4900 | 5500 |

Dimensions(L*W*H)(mm) | 2400*1800*2550 | 2400*2200*2500 | 2600*2450*2650 |

Positioning accuracy(mm) | ±0.005/300 | ±0.005/300 | ±0.005/300 |

Repeat positioning accuracy(mm) | ±0.003 | ±0.003 | ±0.003 |

Spindle speed(RPM) | 8000/10000/12000 | 8000/10000/12000 | 8000/10000/12000 |

Detailed configuration

Main configuration & accessories:

1. Resin sand casting, Meehanite HT-300;

3. X, Y, Z rails adopt stainless steel telescopic cover;

4. Roller type linear guideway from Taiwan

5. Ball lead screw from Taiwan

6. Standard with belt driven spindle, optional for direct driven spindle;

7. Taiwan pneumatic cylinder;

8. Taiwan ATC, umbrella type and disc type are available;

9. Import bearings for leadsrews;

10. Import coupling;

11. Headstock Nitrogen balance system as option;

12. Full enclosed cover;

13. Rigid tapping;

14. Spindle center ring blast;

15. Work lamp;

16. Pilot lamp;

17. USB and Internet interface;

18. Manual pulse generator (MPG);

19. Centralized automatic lubrication system.

20. Cooling system.

21. Heat exchanger for electrical cabinet ;

22. Leveling blocks & bolts;

23. Toolbox and tools;

24. CNC controller: SIEMENS, Fanuc, MITSUBISHI, GSK, Sytec etc.

3. X, Y, Z rails adopt stainless steel telescopic cover;

4. Roller type linear guideway from Taiwan

5. Ball lead screw from Taiwan

6. Standard with belt driven spindle, optional for direct driven spindle;

7. Taiwan pneumatic cylinder;

8. Taiwan ATC, umbrella type and disc type are available;

9. Import bearings for leadsrews;

10. Import coupling;

11. Headstock Nitrogen balance system as option;

12. Full enclosed cover;

13. Rigid tapping;

14. Spindle center ring blast;

15. Work lamp;

16. Pilot lamp;

17. USB and Internet interface;

18. Manual pulse generator (MPG);

19. Centralized automatic lubrication system.

20. Cooling system.

21. Heat exchanger for electrical cabinet ;

22. Leveling blocks & bolts;

23. Toolbox and tools;

24. CNC controller: SIEMENS, Fanuc, MITSUBISHI, GSK, Sytec etc.

Main configuration & accessories:

Features:

1. The CNC Machine Tool Body Has Undergone a Complete Casting Process To Ensure The Quality Of The Product

2. Taiwan Spindle (Speed, Brand, Can Be Matched According To Customer Requirements)

3. Taiwan Ball Screw And Locking Nut

4. Taiwan Pressure Cylinder

5.Japanese NSk Bearing Germany R+W Coupling

6. Automatic Lubrication System

7.Chip Conveyor At Optional (According To Customer Requirements)

Optional Configuration:

System: Syntec,Siemens,Fanuc Mitsubishi

24 Arm Tool Magazine

4th Axis, 5-axis

Spindle Oil Cooling

Chip Conveyor Oil-Water Separator

Air conditioner

Direct-connected electric spindle 12000RPM

1. The CNC Machine Tool Body Has Undergone a Complete Casting Process To Ensure The Quality Of The Product

2. Taiwan Spindle (Speed, Brand, Can Be Matched According To Customer Requirements)

3. Taiwan Ball Screw And Locking Nut

4. Taiwan Pressure Cylinder

5.Japanese NSk Bearing Germany R+W Coupling

6. Automatic Lubrication System

7.Chip Conveyor At Optional (According To Customer Requirements)

Optional Configuration:

System: Syntec,Siemens,Fanuc Mitsubishi

24 Arm Tool Magazine

4th Axis, 5-axis

Spindle Oil Cooling

Chip Conveyor Oil-Water Separator

Air conditioner

Direct-connected electric spindle 12000RPM

More products you are interested in

Company Profile

Shandong Yi Jin numerical control Co., LTD

Shandong Yijin CNC Machine Tool co., Ltd. is a supplier of comprehensive intelligent solutions for efficient,specialized, precision CNC machine tools, modular machine tools, and CNC flexible automatic machining lines. It is a high-tech enterprise in Shandong Province and a key software enterprise in Shandong Province's planned layout. The company has core technologies in the entire intelligent manufacturing industry chain, including processing technology, processing equipment, measurement and testing, and standard formulation. It has strong independent research and development capabilities for specialized machines, equipment remanufacturing, and a complete set of technical services.

Quality is the lifeblood of the enterprise, grasp the details, open innovation. The company invites to join and agent, willing to

work with our customers and strategic partners to create a better future together.

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services

will be provided.

FAQ

1. What is your minimum order quantity and warranty?

A: MOQ is one set, and warranty is one year.

2.What CNC system do you use?

A: FANUC, SIEMENS, MISTSUBISHI, LNC,SYNETC,GSK,etc. It depends on your choice.

3. What is your delivery time ?

The delivery depends on different machines with different configurations. Please contact us to confirm it is in stock or not.

4: What's the MOQ?

A: MOQ is one set, and warranty is one year.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices