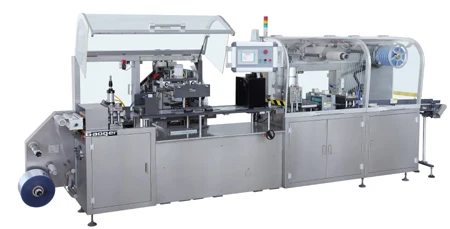

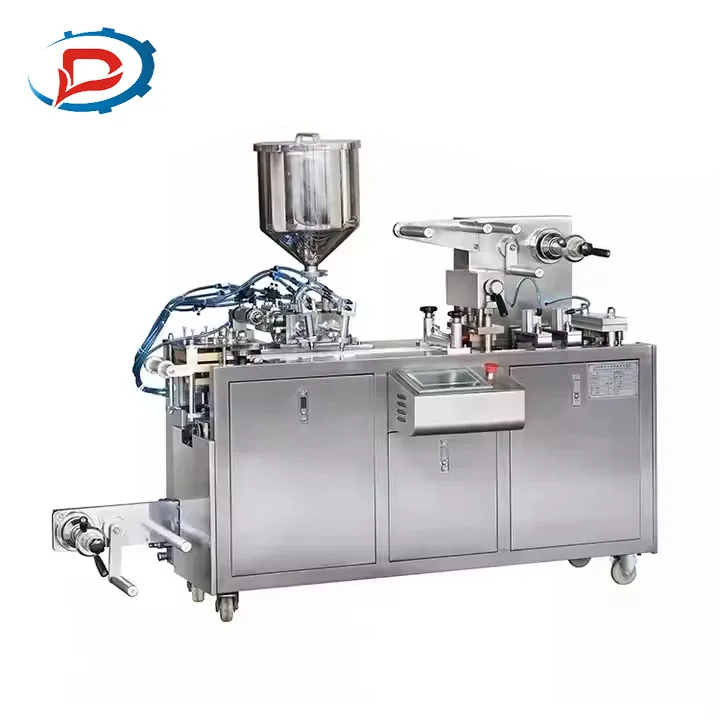

DPP Thermoforming Filling Sealing Packaging Food Honey Chocolate Sauce Full Automatic Liquid Blister Packing Machine

- Category: >>>

- Supplier: Yangzhou Fengyihang Intelligent Equipment Co. Ltd.Yangzhou Ltd.

Share on (1601362617462):

Product Overview

Description

Product Description

Our Fully Automated Blister Packaging Machine (Blister Packing Machine) is a high precision and high-speed packaging solution designed for food items, electronic components, and other small objects. Combining advanced automation technology with robust mechanical construction and intelligent control systems, it realizes a seamless packaging process from feeding, forming, filling, heat sealing to final cutting.

Cutting Frequency (times/min) | 8-35 |

Capacity(strip/h) | 600-2100 |

Max shaping areas and depth (mm) | 80*60*15 |

Stroke (mm) | 20-70 (can be manufactured as user’s requirements) |

Standard Sheet (mm) | 80×57 (can be manufactured as user’s requirements) |

Air Pressure (Mpa) | 0.5-0.7 |

Total power | 380V/220V 50Hz/60Hz 1.8kw |

Main motor power | 0.55KW |

PVC hard pieces (mm) | 0.15-0.5*80 |

PTP Aluminum Foil (mm) | 0.02-0.035*80 |

Dialysis Paper (mm) | 50-100g*80 |

Overall Dimensions (mm) | 1560×460×890 |

Weight (kg) | 380 |

FAQ

What is the DPB-80/100 Flat-plate Blister Packing Machine?

Answer: The DPB-80/100 Flat-plate Blister Packing Machine is a specialized packaging machine used to create blister packs for various products, such as food items, and consumer goods.

What types of products can be packaged using the DPB-80/100 Blister Packing Machine?

Answer: The DPB-80/100 Blister Packing Machine can package different products, such as candies, honey, and other small items that require individual packaging in blister packs.

How does the DPB-80/100 Blister Packing Machine work?

Answer: The machine forms blister packs by heating and molding plastic film or aluminum foil to create individual pockets. It then fills the pockets with products and seals them with a backing material, creating a secure and tamper-proof packaging.

What are the key features of the DPB-80/100 Blister Packing Machine?

Answer: The key features of the DPB-80/100 Blister Packing Machine include automatic feeding, precise temperature and sealing controls, adjustable blister pack sizes, high-speed operation, easy changeover of molds, and user-friendly interface.

What is the production capacity of the DPB-80/100 Blister Packing Machine?

Answer: The production capacity of the DPB-80/100 Blister Packing Machine depends on factors such as product size, blister pack dimensions, and operator efficiency. Generally, it can achieve high-speed packaging, catering to various production demands.

Can the DPB-80/100 Blister Packing Machine handle different blister pack sizes?

Answer: Yes, the DPB-80/100 Blister Packing Machine is designed to accommodate various blister pack sizes. It offers flexibility in adjusting the dimensions of the pockets to match specific product requirements.

Does the machine provide quality control features?

Answer: Yes, the DPB-80/100 Blister Packing Machine often incorporates quality control features, such as automatic rejection of defective packs, vision inspection systems, and precise sealing controls. These features ensure product quality and minimize packaging errors.

Is technical support available for the DPB-80/100 Blister Packing Machine?

Answer: Yes, reliable technical support is usually available for the DPB-80/100 Blister Packing Machine. Manufacturers provide assistance with installation, training, spare parts availability, and ongoing support to ensure smooth operation and maintenance.

Can the DPB-80/100 Blister Packing Machine be integrated with other packaging equipment?

Answer: Yes, the DPB-80/100 Blister Packing Machine can be integrated with other packaging equipment, such as cartoning machines or labeling systems, to create a complete packaging line. This integration enhances overall efficiency and productivity in the packaging process.

Answer: The DPB-80/100 Flat-plate Blister Packing Machine is a specialized packaging machine used to create blister packs for various products, such as food items, and consumer goods.

What types of products can be packaged using the DPB-80/100 Blister Packing Machine?

Answer: The DPB-80/100 Blister Packing Machine can package different products, such as candies, honey, and other small items that require individual packaging in blister packs.

How does the DPB-80/100 Blister Packing Machine work?

Answer: The machine forms blister packs by heating and molding plastic film or aluminum foil to create individual pockets. It then fills the pockets with products and seals them with a backing material, creating a secure and tamper-proof packaging.

What are the key features of the DPB-80/100 Blister Packing Machine?

Answer: The key features of the DPB-80/100 Blister Packing Machine include automatic feeding, precise temperature and sealing controls, adjustable blister pack sizes, high-speed operation, easy changeover of molds, and user-friendly interface.

What is the production capacity of the DPB-80/100 Blister Packing Machine?

Answer: The production capacity of the DPB-80/100 Blister Packing Machine depends on factors such as product size, blister pack dimensions, and operator efficiency. Generally, it can achieve high-speed packaging, catering to various production demands.

Can the DPB-80/100 Blister Packing Machine handle different blister pack sizes?

Answer: Yes, the DPB-80/100 Blister Packing Machine is designed to accommodate various blister pack sizes. It offers flexibility in adjusting the dimensions of the pockets to match specific product requirements.

Does the machine provide quality control features?

Answer: Yes, the DPB-80/100 Blister Packing Machine often incorporates quality control features, such as automatic rejection of defective packs, vision inspection systems, and precise sealing controls. These features ensure product quality and minimize packaging errors.

Is technical support available for the DPB-80/100 Blister Packing Machine?

Answer: Yes, reliable technical support is usually available for the DPB-80/100 Blister Packing Machine. Manufacturers provide assistance with installation, training, spare parts availability, and ongoing support to ensure smooth operation and maintenance.

Can the DPB-80/100 Blister Packing Machine be integrated with other packaging equipment?

Answer: Yes, the DPB-80/100 Blister Packing Machine can be integrated with other packaging equipment, such as cartoning machines or labeling systems, to create a complete packaging line. This integration enhances overall efficiency and productivity in the packaging process.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices