Professional manufacture customerized high output and quality ABA polyethylene film blowing extrusion machine for plastic bags

- Category: Blown Film Production Line >>>

- Supplier: Zhejiang Songshan Machinery Co. Ltd. [Zhejiang China]Zhejiang

Share on (60701291946):

Product Overview

Description

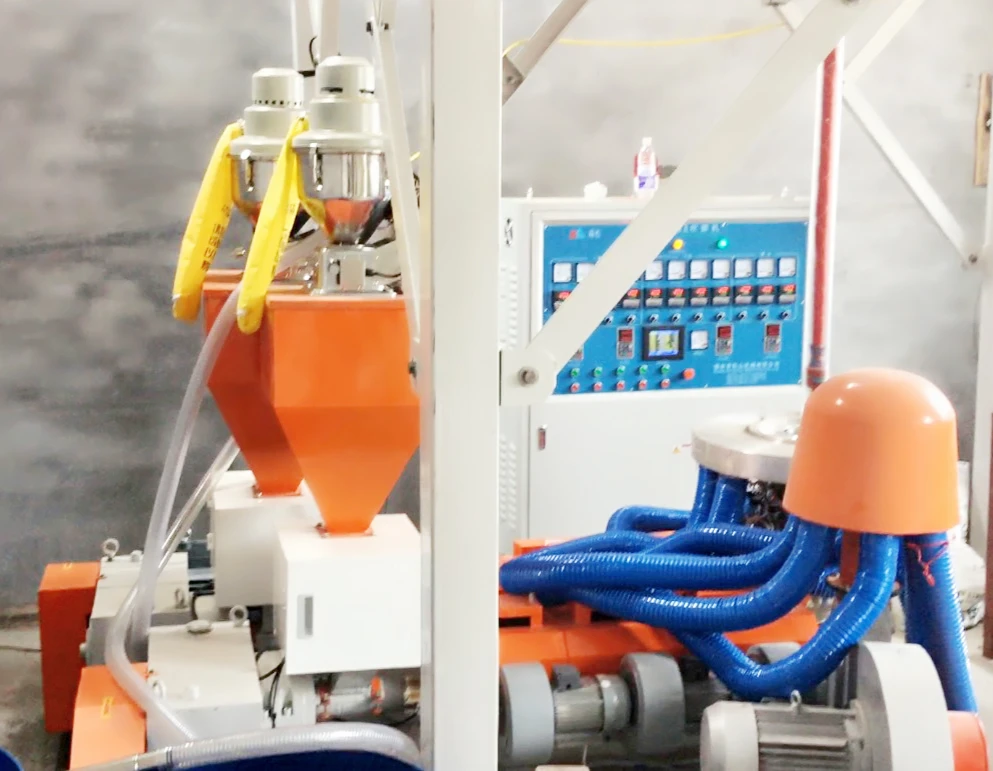

Professional manufacture customerized high output and quality ABA polyethylene film blowing extrusion machine for plastic bags

Wenzhou Ruian Songshan ABA PE FILM BLOWING MACHINE

ABA Three Layers Co-extrusion Film Blowing Machine adopts special co-extrusion A+B+A film blowing die and has unique features in the production of HDPE, LDPE and LLDPE material. The physical strength of the film is enhanced through multiple-layers. The application of one host machine to supply materials for inner and outer layers which can reduce the configuration of the other host, to cut cost, save energy and lower consumption.

The Film blowing machine is used to blow the plastic films like LDPE (low density polyethylene), HDPE (high density polyethylene) and LLDPE (linear low density polyethylene) into bubble film. Its products are widely used to pack fruit, food, clothes, textile, like garbage bags and vest/T-shirt bags, shopping bags and daily necessities and other industrial products.

ABA Film Blowing Machine

Model | ABA-900 | ABA-1200 | ABA-1400 |

main material | HDPE | ||

film width | 800mm | 1000mm | 1200mm |

output | 60kgs/H | 75kgs/H | 100kgs/H |

screw diameter | 45mm×2pcs | 50mm×2pcs | 55mm×2pcs |

gearbox | 146 | 146 | 173 |

motor capacity | 15KW | 18.5KW | 22KW |

die size | 60mm | 80mm | 100mm |

air blower | 2.2KW | 3KW | 5.5KW |

roller width | 900mm | 1200mm | 1400mm |

taking up speed | 0-60m/min | ||

winding type | fraction type single winder | ||

winding diameter | 650mm | ||

Dimension | 4×3×4.5M | 4×3.5×6M | 4.5×4×7M |

Low pressure polyethylene (HDPE) and linear low density polyethylene (LLDPE) are new varieties of polyethylene in the international market. It has advantages of impact strength, penetration-resistance, environmental stress crack resistance, and low temperature resistance, especially it can be used to make micro-thin films (the film strength of 0.015 mm film is as much as that of 0.03mm high-pressure polyethylene film).

Reworked materials or other affordable materials like 50% calcium carbonate can be used without affecting the strength, weldability, printing properties of the products; and the cooling becomes faster and the yield is higher because of the calcium carbonate or low pressure polyethylene in the interlayer.

We Recommend

HAS VIDEO HDPE LDPE extruders for plastic film

China manufacturer good quality pvc blow film machine for sale

New Arrivals

New products from manufacturers at wholesale prices