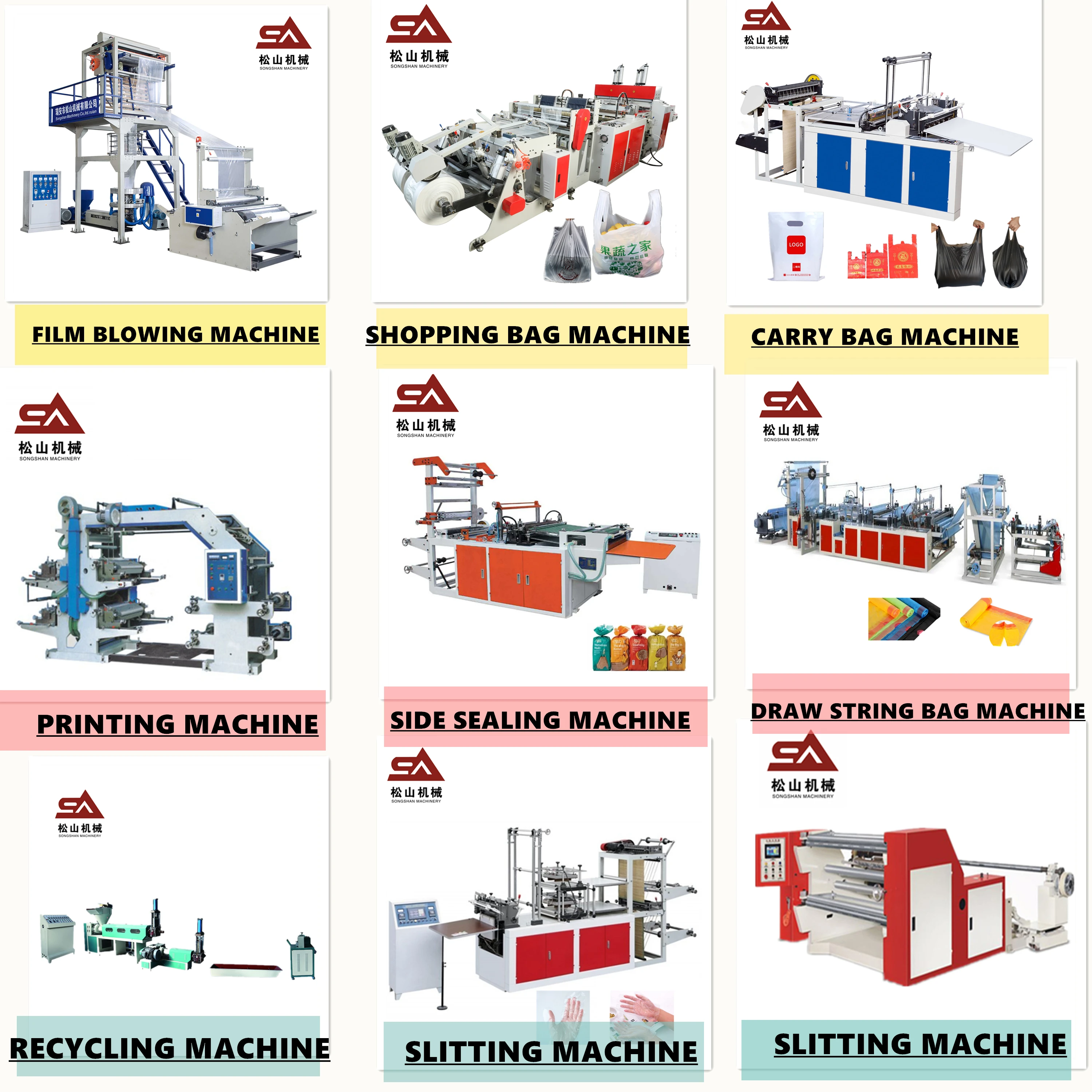

Professional Manufacturers direct selling ce costomerized easy used energy conservation new pe film blow machine

- Category: Blown Film Production Line >>>

- Supplier: Zhejiang Songshan Machinery Co. Ltd.

Share on (60701459994):

Product Overview

Description

Professional Manufacturers direct selling ce costomerized easy used energy conservation new pe film blow machine

The Blow film extruder machine is used to blow the plastic films like LDPE (low density polyethylene), HDPE (high density polyethylene) and LLDPE (linear low density polyethylene) into bubble film. Its products are widely used to pack fruit, food, clothes, textile, like garbage bags and vest/T-shirt bags, shopping bags and daily necessities and other industrial products.

HDPE/LDPE film blowing machine series SJ-50, SJ-55, SJ-65

Model | SJ-50 | SJ-55 | SJ-65 | |

Features | Raw Material | HDPE, LDPE, LLDPE; Virgin and Recycled | ||

Film Width | 600mm | 800mm | 1200mm | |

Output | 30Kgs | 40Kgs | 65Kgs | |

Film Thickness | 0.01mm-0.15mm | |||

Dimension | 4×3×4M | 5×3.5×4.5M | 6×4×5.5M | |

Extrusion Unit | Screw Diameter/LD ratio | 50mm | 55mm | 65mm |

Motor | 11KW | 15KW | 22KW | |

Gearbox | 133 | 146 | 173 | |

Die Head Type | Fixed Die Head | |||

Die Size | 50/80mm | 80/160mm | 160/260mm | |

Taking-up Tower | Upper Tower Type | Up and down; embossing roller and gusseting | ||

Roller Length | 700mm | 900mm | 1400mm | |

Roller Working Way | Opened and Tightened By Air Cylinders | |||

Winding Station | Winder Type | Single winding fraction type | ||

Rollers | 700mm | 900mm | 1400mm | |

Winding Diameter | 650mm | |||

Control Panel | Electronics | Top China Brand | ||

Film blowing machine features:

Material of screw and barrel: Alloyed high-quality steel 38CrMoAlA with optimum hardness and strong corrosion resistance after precision finishing and nitrogen treatment

Heaters: stainless heaters

Film blowing machine control Panel

1. Temperature of barrel and die head controlled by digital temperature controller

2. Inverter controls main motor driving speed and film taking up motor running speed

3. Electronics used are all Chinese top brand

4. Current meters and Voltage meters show the working state of motors

5. Small fan installed to avoid high temperature caused by long time running

We Recommend

HAS VIDEO HDPE LDPE extruders for plastic film

China manufacturer good quality pvc blow film machine for sale

New Arrivals

New products from manufacturers at wholesale prices