800 тонн сервопривода CNC SMC септический резервуар гидравлический пресс

- Category: Hydraulic Press >>>

- Supplier: Tengzhou Baixing Machinery Co. Ltd.

Share on (62206114027):

Product Overview

Description

Product Application

800-ton water tank hydraulic press Suitable for press forming of SMC BMC PE PP and other materials. The machine adopts three-beam four-column structure, simple and practical, low failure rate and good maintenance. Our company exports hydraulic presses from all over the world all the year round.

Main Features

This series of presses is a general-purpose hydraulic press, also known as universal hydraulic press. It is suitable for the stretching, bending, flanging, cold extrusion, punching and other processes of metal materials. It is also suitable for calibration, press-fit, powder products, abrasive products. Molding and press molding of plastic products and insulating materials.

The working pressure, pressing speed and stroke of the machine can be adjusted within the specified parameters according to the process requirements. This machine has independent power mechanism and electrical system, and adopts button centralized control, which can realize manual, semi-automatic and two operation modes. It can realize two pressing methods: constant pressure and fixed stroke.

Equipment use conditions:

1. Equipment working area temperature: -10~60°C (±)

2, power supply: three-phase four-wire system 380V, 50HZ, voltage fluctuation range 380V ± 10%

3, cooling method: water cooling device

4, the hydraulic system uses the medium: No. 46 anti-wear hydraulic oil

Machine parameters

Nominal force: 8000KN

Maximum working pressure of liquid: 25MPa

Slider effective stroke: 1200mm

Maximum opening height: 1800mm

Effective area of the workbench:

1500mm inside and outside the column

Front and rear edges 1000mm

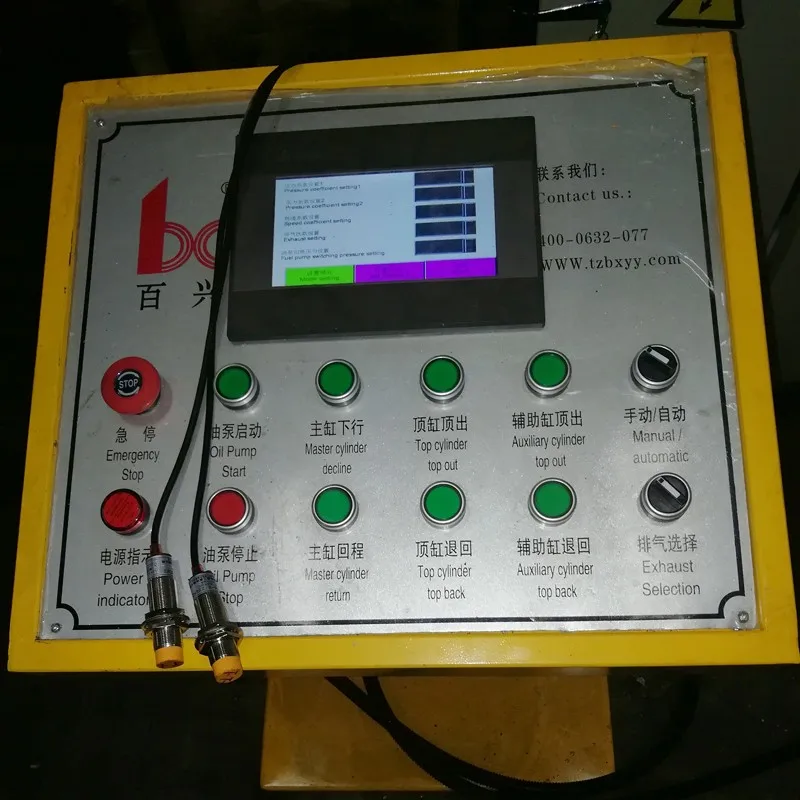

Operation interface

PLC smart computer can compile more than 100 templates

Chinese and English logo button operation at a glance

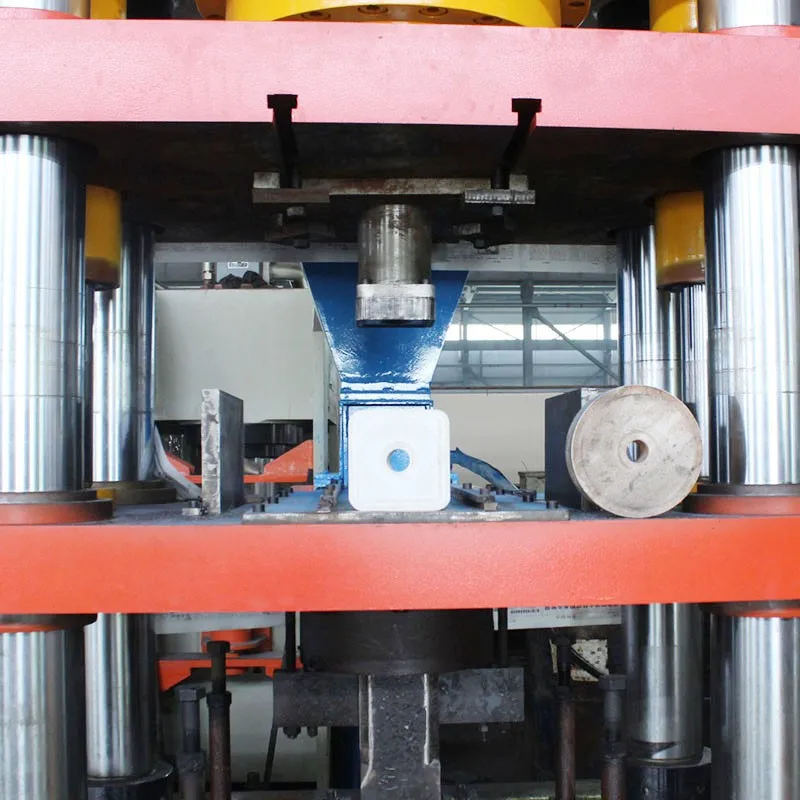

Mechanical detail

Equipped with an ejector cylinder for loading and stretching

Electrical part

Configure brand-name appliances, servo motors are more energy efficient

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

| \t | |

| \t | \t |

| \t | \t |

| \t | \t |

Salt block forming machine

91.8% Response Rate

Head stretching machine

91.8% Response Rate

315 stretching machine

91.8% Response Rate

We Recommend

Hydraulic Manual Punching Machine

500 ton hydraulic press sheet metal forming press machine

New Arrivals

New products from manufacturers at wholesale prices