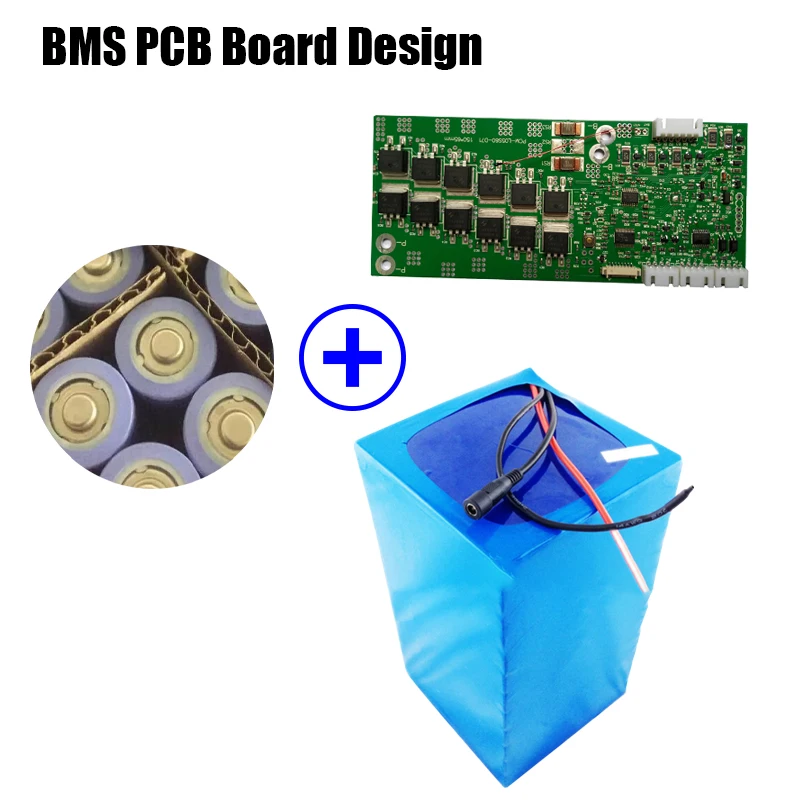

3S 6S 12V 18650 10A BMS зарядное устройство защитная плата для литий ионной литиевой батареи

- Category: >>>

- Supplier: Shenzhen Moko Technology Ltd.

Share on (62220497080):

Product Overview

Description

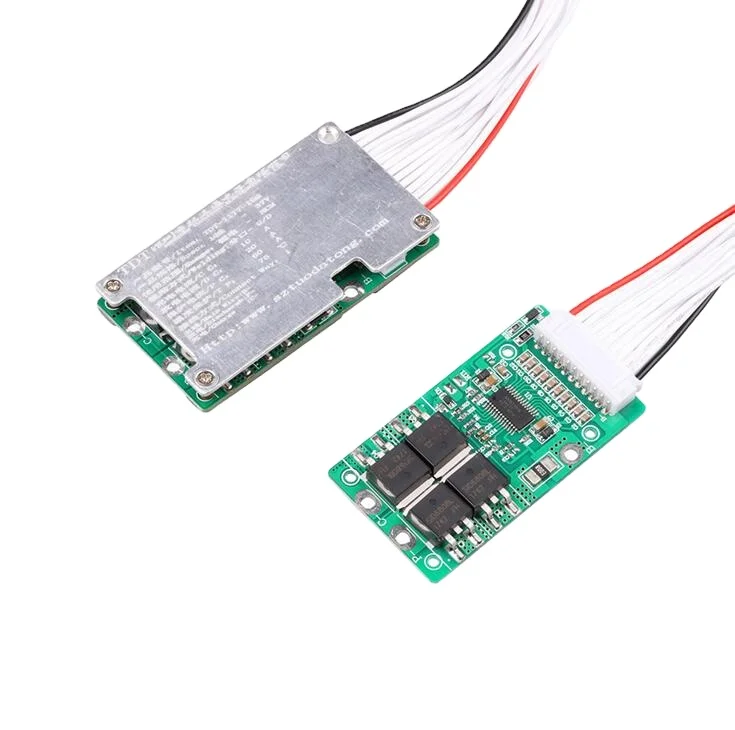

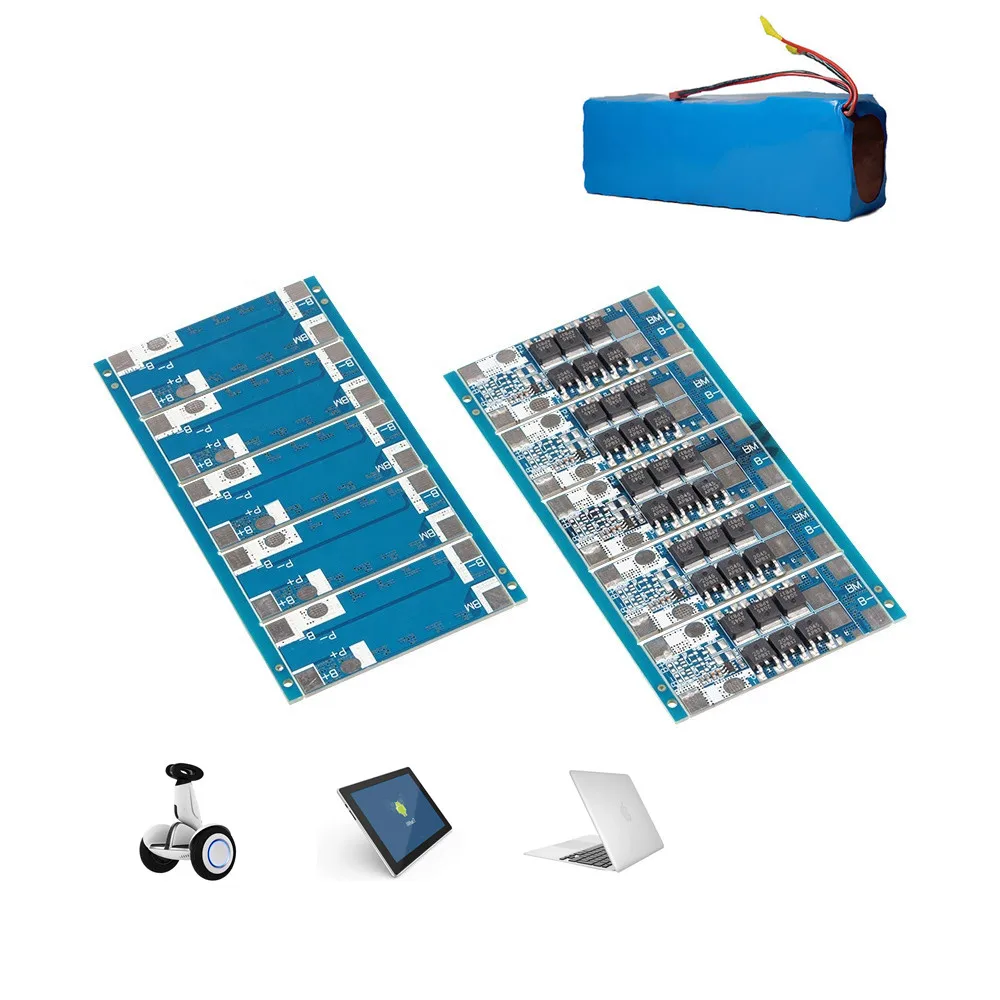

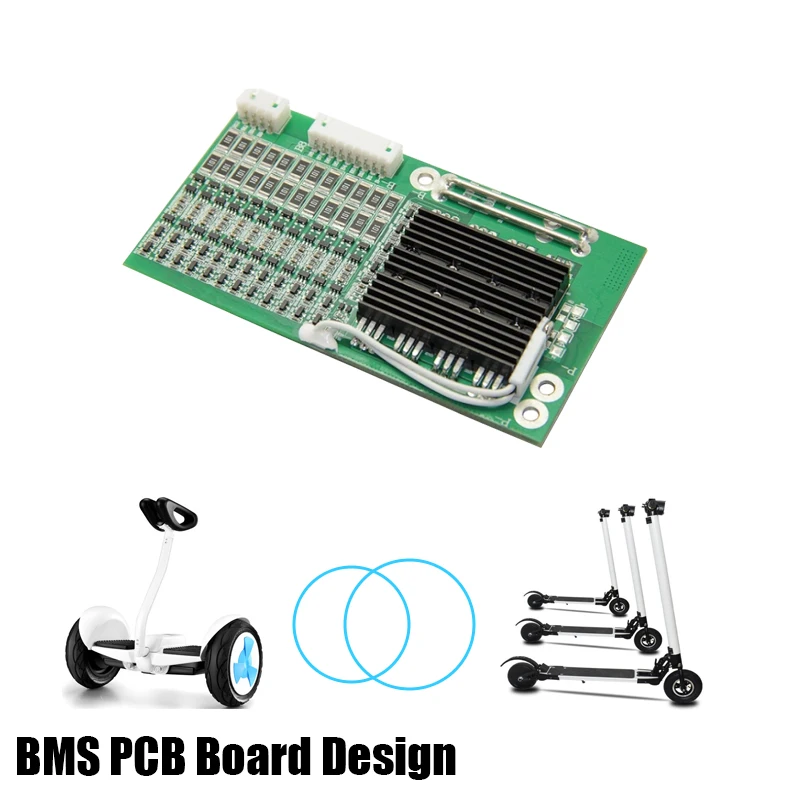

3S 6S 12V 18650 10A BMS Charger Li-ion Lithium Battery Protection Board

Welcome To Moko

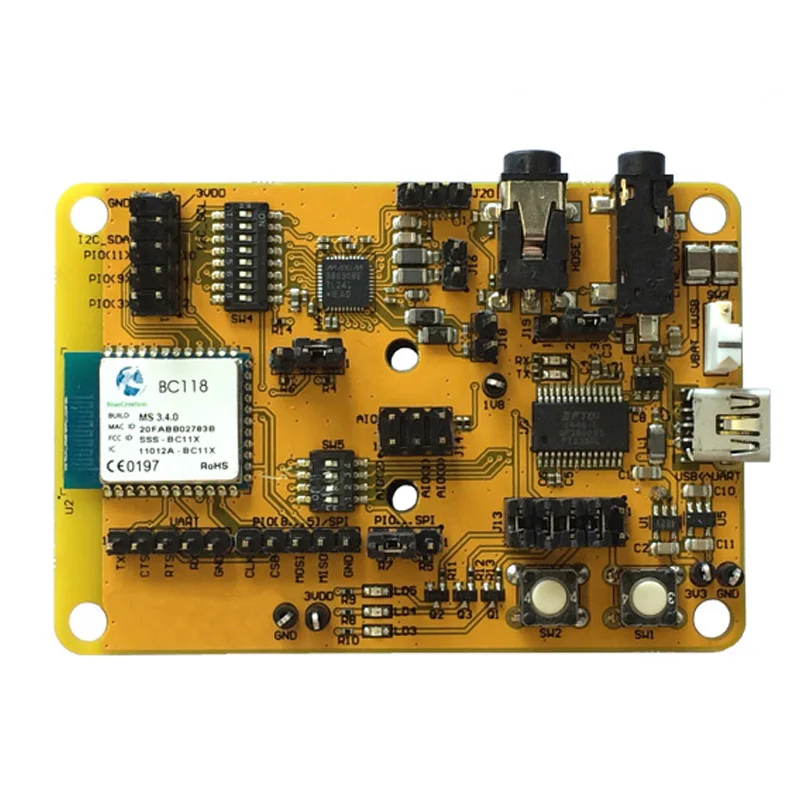

Founded in the year 2006,located in Shenzhen, as a professional EMS/OEM Manufacturer, MOKO TECHNOLOGY LTD could provide one-stop pcb assembly service,we also could offer:

- Contract Manufacturing

- Engineering Services

- PCB Assembly

- Component Procurement & Material Management

- Fast Track Prototyping

- Cable and Wire Assemblies

- Plastics and Molds

- Function Testing Service

As the Professional PCB Assembly and PCB Manufacturer in China, we pride ourselves on our Excellent Customer Service and Reliability! MOKO Technology Ltd also offers Exclusive Services to Help Our Customers with their PCB Projects.

*PCB board manufacture and PCBA service:

* Electronic testing circuit board or PCBA

* Fast delivery, anti-static package

* RoHS Directive-compliant, lead-free

* One stop service from PCB manufacture, components

purchasing, PCB assembly, test, packing and PCB delivery

* Electronic manufacturing service

*Detailed terms for PCB assembly:

1. Professional surface-mounting and through-hole soldering technology

2. Various sizes like 1206, 0805, 0603 components SMT technology

3. ICT (in circuit test), FCT (functional circuit test) technology

4. PCB assembly with UL, CE, FCC, RoHS approval

5. Nitrogen gas reflow soldering technology for SMT

6. High standard SMT and solder assembly line

7. High density interconnected board placement technology capacity

Our PCB Sevices:

1. PCB fabrication.

2. Turnkey PCBA: PCB+components+SMT and through-hole assembly+enclosure molding&housing.

Our Advantage:

1. Free programming and free functional test, free package.

2. High quality: IPC-A-610E standard, E-test, X-ray, AOI test, QC, 100% funtional test.

3. Professional service. ISO SMT and through hole assembly, over 10 years experience.

4. Certification for electronics: UL, 94v-0, CE, SGS, FCC, RoHS, ISO9001:2008, ISO14001

5. Warranty period for PCBA: 2 years.

PCBA PROCESSING CAPABILITY :

| Turnkey PCBA | PCB+components sourcing+assembly+package |

| Assembly details | SMT and Thru-hole, ISO SMT and DIP lines |

| Lead Time | Prototype: 15 work days. Mass order: 20~25 work days |

| Testing on products | Flying Probe Test, X-ray Inspection, AOI Test, Functional test |

| Quantity | Min quantity: 1pcs. Prototype, small order, mass order, all OK |

| Files needed | PCB: Gerber files(CAM, PCB, PCBDOC) |

| Components: Bill of Materials(BOM list) | |

| Assembly: Pick-N-Place file | |

| PCB Panel Size | Min size: 0.25*0.25 inches(6*6mm) |

| Max size: 20*20 inches(500*500mm) | |

| PCB Solder Type | Water Soluble Solder Paste, RoHS lead free |

| Components details | Passive Down to 0201 size |

| BGA and VFBGA | |

| Leadless Chip Carriers/CSP | |

| Double-sided SMT Assembly | |

| Fine Pitch to 0.8mils | |

| BGA Repair and Reball | |

| Part Removal and Replacement | |

| Component package | Cut Tape,Tube,Reels,Loose Parts |

PCB PROCESSING CAPABILITY :

| 1 | Layers | Single Sided,2 to 18 Layer |

| 2 | Board material type | FR4,CEM-1,CEM-3,ceramic substrate board, aluminum based board, high-Tg, Rogers and more |

| 3 | Compound material lamination | 4 to 6 layers |

| 4 | Maximum dimension | 610 x 1,100mm |

| 5 | Dimension tolerance | ±0.13mm |

| 6 | Board thickness coverage | 0.2 to 6.00mm |

| 7 | Board thickness tolerance | ±10% |

| 8 | DK thickness | 0.076 to 6.00mm |

| 9 | Minimum line width | 0.10mm |

| 10 | Minimum line space | 0.10mm |

| 11 | Outer layer copper thickness | 8.75 to 175µm |

| 12 | Inner layer copper thickness | 17.5 to 175µm |

| 13 | Drilling hole diameter (mechanical drill) | 0.25 to 6.00mm |

| 14 | Finished hole diameter (mechanical drill) | 0.20 to 6.00mm |

| 15 | Hole diameter tolerance (mechanical drill) | 0.05mm |

| 16 | Hole position tolerance (mechanical drill) | 0.075mm |

| 17 | Laser drill hole size | 0.10mm |

| 18 | Board thickness and hole diameter ratio | 10:1 |

| 19 | Solder mask type | Green, Yellow, Black, Purple, Blue, White and Red |

| 20 | Minimum solder mask | Ø0.10mm |

| 21 | Minimum size of solder mask separation ring | 0.05mm |

| 22 | Solder mask oil plug hole diameter | 0.25 to 0.60mm |

| 23 | Impedance control tolerance | ±10% |

| 24 | Surface finish | Hot air level, ENIG, immersion silver, gold plating, immersion tin and gold finger |

PCB Assembly Manufacturing Procedures:

* Program Management

PCB Files → DCC → Program Organizing → Optimization → Checking

* SMT Management

PCB Loader → Screen Printer → Checking → SMD Placement → Checking → Air Reflow → Vision Inspection → AOI → Keeping

* PCBA Management

THT→Soldering Wave (Manual Welding) → Vision Inspection → ICT → Flash → FCT → Checking → Package → Shipment

Layer Details | Sample(Normal) | Sample(Fast) | Mass Production |

Single/Double | 2-3days | 24hours | 5-7days |

Four Layer | 7-10days | 3days | 7-10days |

Six-Eight Layer | 7-10days | 5days | 13-15days |

Over Eight Layer | 15-20days | 7days | 15-20days |

Components Sourcing:

Procedure:

Supplier → Components Purchase → IQC → Protection Control(Warehouse)

Q: What files do you use in PCBA fabrication?

A: Gerber or Eagle, BOM listing, PNP and Components Position

Q:Is it possible you could offer sample?

A: Yes, we can custom you sample to test before mass production

Q: When will I get the quotation after sent Gerber, BOM and test procedure?

A: Within 6 hours for PCB quotation and around 24 hours for PCBA quotation.

Q: How can I know the process of my PCBA production?

A: 7-10 days for PCB production and components purchasing, and 10 days for PCB assembly and Testing

Q: How can I make sure the quality of my PCBAs?

A: We ensure that each piece of PCBA products work well before shipping. We'll test all of them according to your test procedure. Also if there are any defect items during the shipping, we also can be free to repair for you.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices