TSH 35 лаборатории/мини экструдер Двухшнековый машины натриевый вкладыш GCL

- Категория: Plastic Extruders >>>

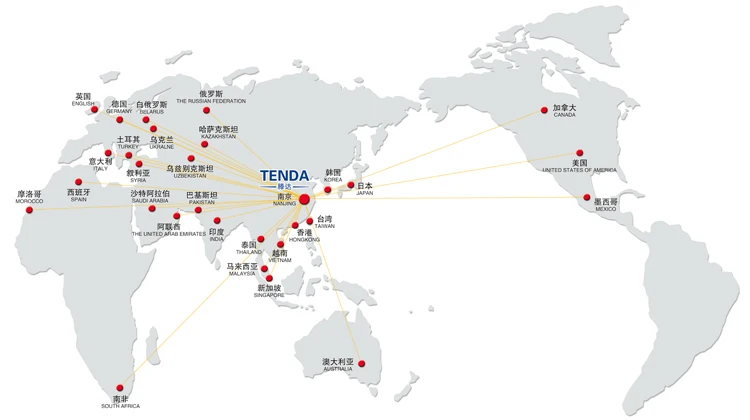

- Поставщик: Nanjing Tengda Machinery Co. Ltd.

Сохранить в закладки 1600338546434:

Описание и отзывы

Характеристики

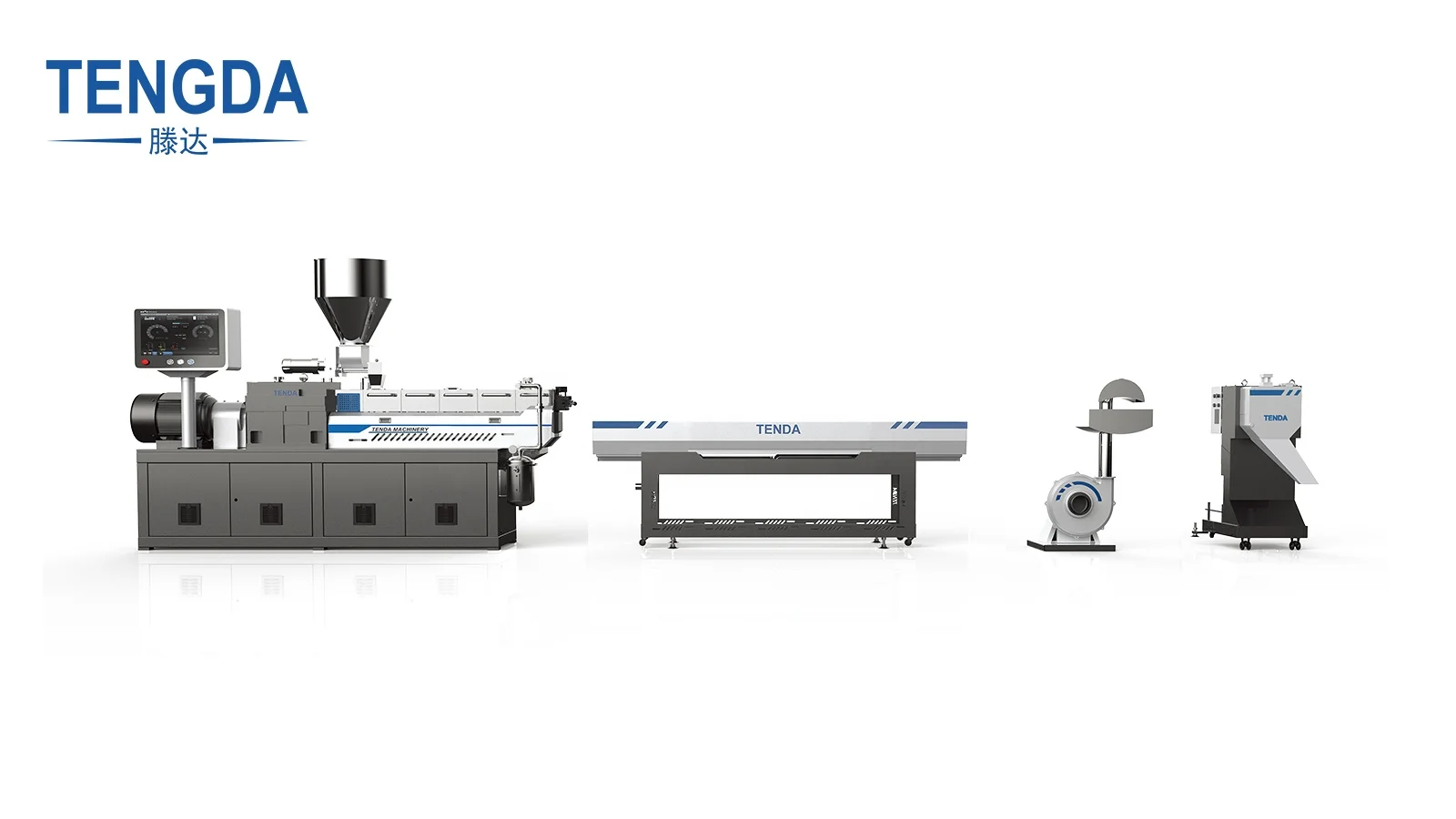

TSH-35 Laboratory mini equipment for Plastic granules extruder machine

Lab/ mini Waste Plastic Recycling Extruder Machine price for SBS PP PEcan test even only a small amount of material, especially for color-matching, raw material evaluation, new formula research and development and pre-screening for pre-mixing materials.

Lab/ mini Waste Plastic Recycling Extruder Machine price for SBS PP PE is handy and convenient with attractive price-performance ratio, and is the best choice for various institutes labs,universities and research institutes.

.

TSH-35 Laboratory mini equipment for Plastic granules extruder machine

TSH-35 Laboratory mini equipment for Plastic granules extruder machine Features

1) Just work in and out of the water ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.3) The use of advanced variable frequency motors can save energy.

4) Running in a high automatization and intellectualization, less pollution

Extruder Machine About materials

Our Extruder machine advantages

All main motors of machine use Variable Frequency Motor(AC), eliminating three-phase asynchronous motors;

1. Variable Frequency Motor:

(1) Speed regulation is easy and energy saving.

(2) AC motor has simple structure, small volume, small inertia, low cost, easy maintenance and durability.

(3) It can expand output and achieve high speed and high voltage operation.

(4) Soft start and fast brake can be achieved.

(5) No spark, explosion-proof, and strong environmental adaptability.

2.High output:

Take "PP" material as an example, the PP material is tested on the customer's site, our Lab/ mini Waste Plastic Recycling Extruder Machine price for SBS PP PE actual production output is 10%-20% higher than the same model in the market;

3.Simple installation:

The Lab/ mini Waste Plastic Recycling Extruder Machine price for SBS PP PE is easy to install, only need to be connected to the inlet and outlet water, which can save 2 days of installation time;

4.Advanced design:

All electrical components are imported famous brands, like German "SIEMENS", France "SCHNEIDER", United States "CEME", Japan "ORMON" "TOSHIBA" "FUJI" etc.;

The Lab/ mini Waste Plastic Recycling Extruder Machine price for SBS PP PE first advanced dust cover design, beautiful appearance and simple maintenance;

Use a thicker and more heat-resistant heater to ensure the heating effect of the barrel and the service life of the heater;

The water cooling system of the barrel adopts stainless steel pipes and valves;

5.products

High viscosity and high transparency

6.Good after-sales service:

The warranty of main gearbox is extended for free for three years;

Modernized CNC processing equipment to fundamentally guarantee the supply of quantity and quality of Lab/ mini Waste Plastic Recycling Extruder Machine price for SBS PP PE spare parts;

We provide engineers overseas installation service of plastic extruder machine .

Packaging | ||

Size | 123 (L) * 456 (W) * 789 (D) | |

Packaging Details | (1) Paint anti-rust oil; (2) Wrapped by the stretch film or bubble film; (3) Put it in the container or wooden box. The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. | |

Presales service:

>Introducing in detail features and application of the products to customer.>Providing operation data of the related TSH-35 Laboratory mini equipment for Plastic granules extruder machine

>Providing means of trial performance for customer.

Sales service:

>Recommending engineering conditions required for installation of the TSH-35 Laboratory mini equipment for Plastic granules extruder machine

>Communicating in time the manufacturing progress of the machine with user.

>Providing assistance in technical conditions, screw combination and barrel disposition needed for product.

After-sales service:

>Providing on-the-spot technical assistance in installation, commission and training.

>Filling in detail customer's information.

>Providing long-term maintenance service and spare parts.

>Giving technical support to customer for developing new product.

>Providing free maintenance for a year of TSH-35 Laboratory mini equipment for Plastic granules extruder machine

1)Are you trading company or manufacturer?

A: We are factory.We have the technical production team,and the workers are all very experienced.

Q: Why choose you?

A:You can get a very fair price from us and our price can make you beat your competitors in the market.

Our Excellent Service

For a quick, no hassle quote just send email to us

We promise to reply with a price within 24 hours - sometimes even within the hour.

If you need an advice, just call our export office at +86 025 52296133, we will answer your questions immediately.

3) Our quick manufacturing time

For Normal orders, we will promise to produce within 30 working days.

As a manufacturer, we can ensure the delivery time according to the formal contract.

Q: What kind of certification do you have?

A: Our products have obtained ISO9001 and CE certification,the quality can be guaranteed.We focus on the field of extrusion machine,and aim to be the best manufacturer of this field.

Q:What's the payment?

A:L/C, T/T, Western Union, Paypal, Money Gram.

Похожие товары

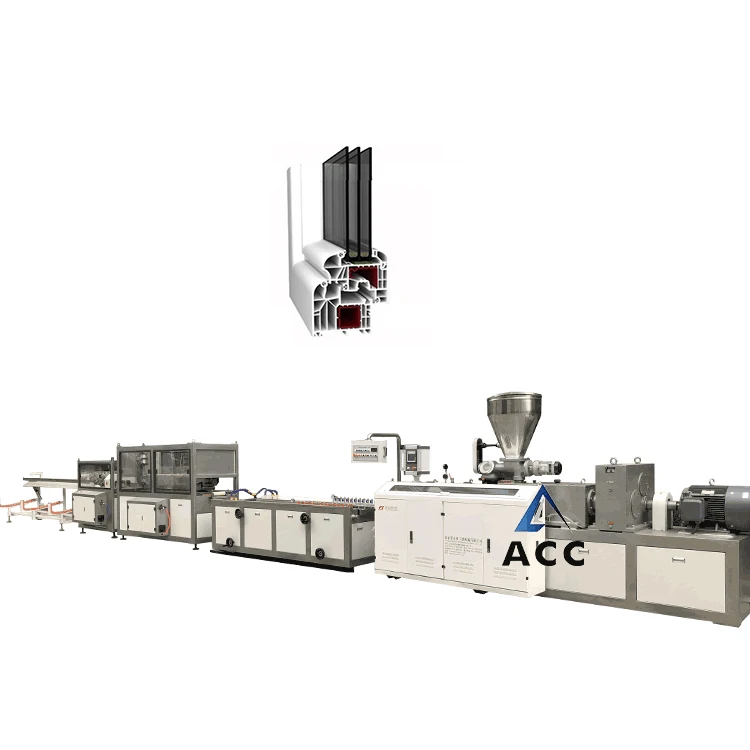

Оборудование для экструзии пластиковых труб

Машина для изготовления потолочных панелей из ПВХ, машина для изготовления потолочных панелей из ПВХ для изготовления стен из пластиковых панелей

Машина для изготовления пола из ПВХ SPC

603*603*7 мм ПВХ квадратная потолочная производственная линия, ПВХ 595*595 мм машина для производства внутренней крыши

Линия по производству дверных панелей из ПВХ

Шанхай Shenxin высокоскоростная фабрика точно изготовленная пластиковая воздушная пузырчатая пленка, рулон листа, производственная машина

Машина для производства листов пенопласта EPE/Экструзионная линия ПЭ-труб из пенопласта, модель Элли Whats 008613780912769

Новые поступления

Новинки товаров от производителей по оптовым ценам