Сертификация качества Полная производственная линия по производству питьевых вод в бутылках галлонов/машина для розлива минеральной воды

- Категория: >>>

- Поставщик: Zhangjiagang Links Machine Co. Ltd.

Сохранить в закладки 1601270539080:

Описание и отзывы

Характеристики

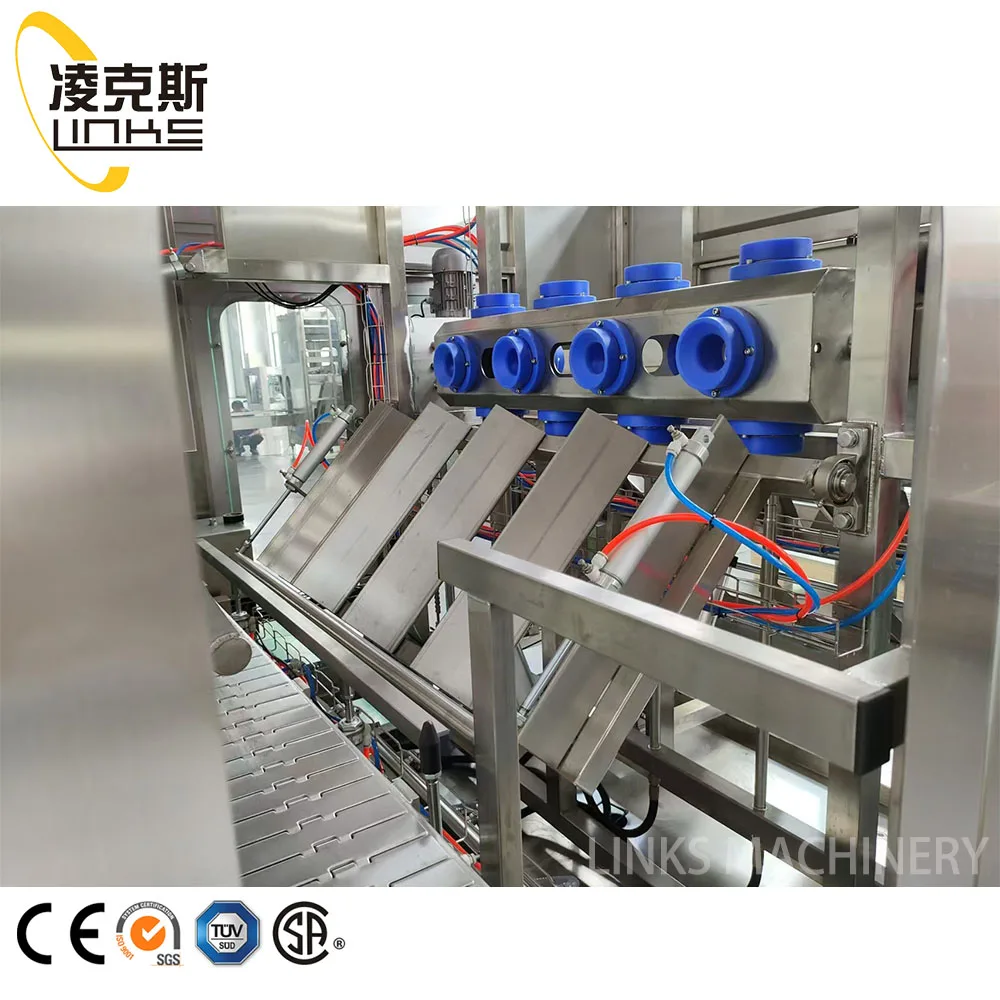

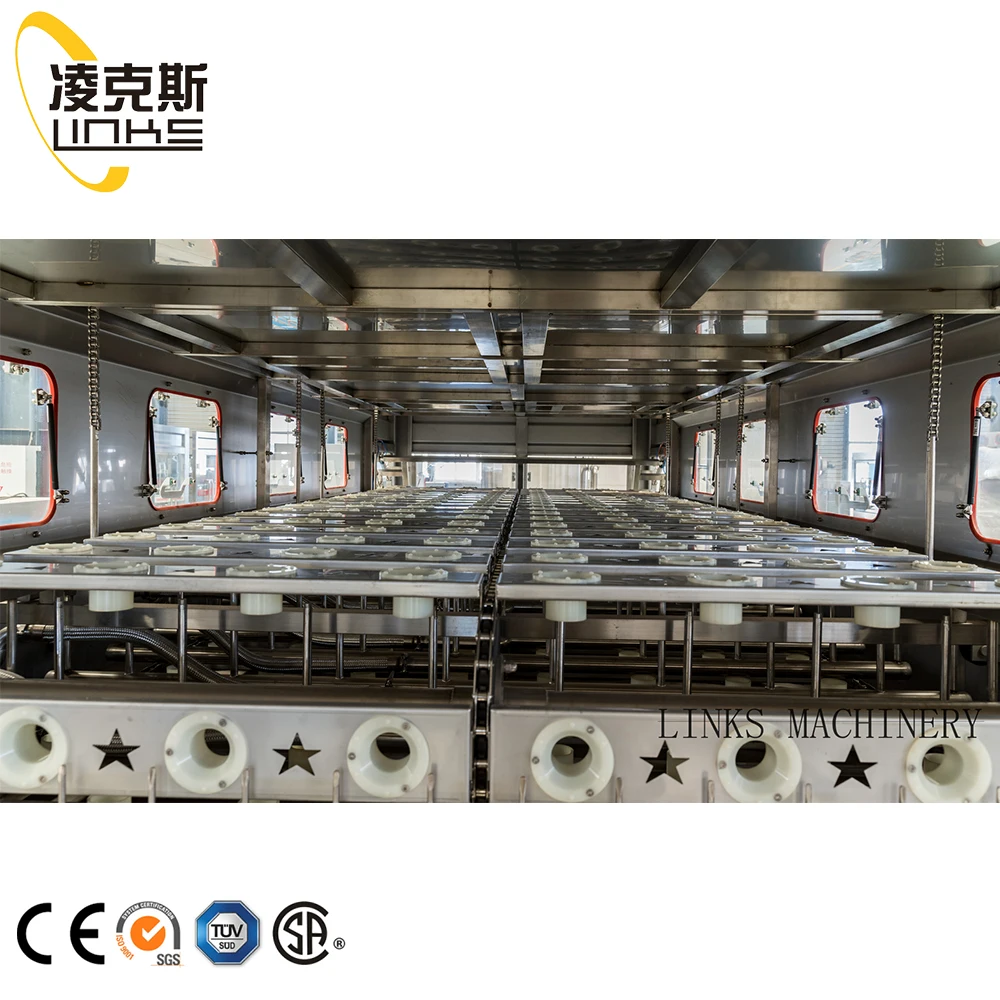

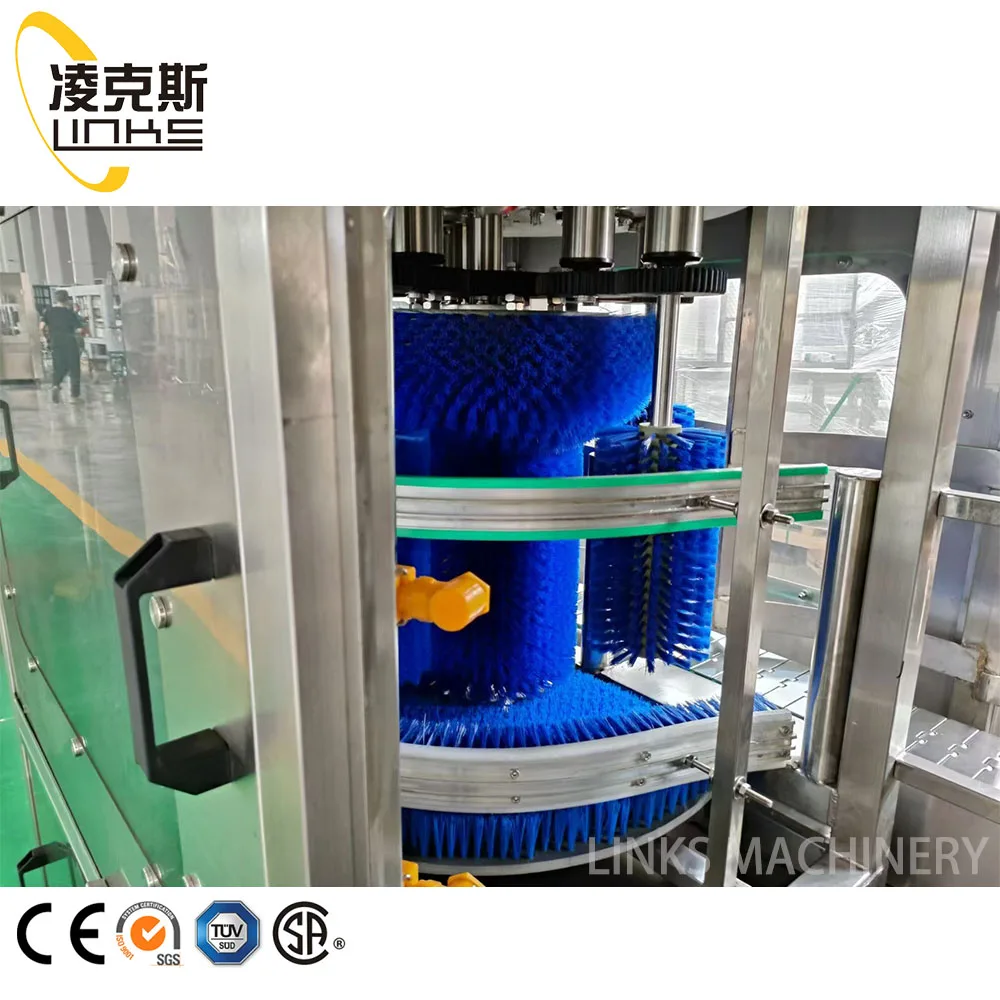

| 1.Washing Heads <1>Using the reversal bottles washing type, bottle clamp stuck bottleneck,avoid the pollution by traditional rubber clip. <2>Bottle clamp and lifting mechanism of sliding sleeve adopts Germany igus corrosion resistant bearing no need maintenance. <3>All rinse heads adopt food grade stainless steel 304/316. |

| Filling Heads <1>Adopt high speed and precision filling valve structure design,The filling volume is finely adjustable and accurate. <2>All filling valve sealing materials using ozone resistance, corrosion-resistant sealing ring. <3>Filling nozzle,contact parts & liquid tank,filling pump,adopt food grade stainless steel 304/316. |

| 3.Capping Heads <1>All food grade304/316 stainless steel construction <2>The capper is equipped with inlet bottle detection switch.Centrifugal way of cap arranging is adopted to reduce damage of caps. <3>Automatically stop when no bottle <4>Capping effect is stable and reliable ,Defective rate ≤0.2% . |

We also provide the Complete Automatic Water Bottling Plant

It Includes 5 main parts:

1/ Plastic bottle blow molding machine

2/ Water cleaning system

3/ Water washing, filling, capping machine.

4/Conveyor system, labeling machine, dating machine, film wrapping machine

The complete line main description:

1/ The plant can produce different volume bottles, from 150ml to 2000ml bottles, round and square bottles, plastic and glass bottles. It is very easy to change the different bottle molds.

2/ The plant is highly automatic, you can operate on the touch screen to adjust the machine speed and working.

3/ We have different speed plants, commonly, 2000BPH, 5000BPH, 7000BPH, 10,000BPH, 12,000BPH, 15000BPH,18000BPH..ect 36000BPH.

4/ The material is stainless steel 304, food grade much clean and safe.

5/ We provide the engineers for customer installation, training in customer's factory.

1,Reverse Osmosis RO System Water Treatment

It can be used in various commercial fluids, including drinking water, carbonated beverages, juice, tea and alcohols.

(1)Raw water→ Raw water tank→Raw water pump

(2)Quartz sand filter→ Activated carbon filter→Sodium-ion exchanger→Ultra filter

(3)High pressure pump Reverse Osmosis

(4)Qzone sterilizer→ Pure water tank.

Bottle Blowing Machine This machine is use for kinds of different shape bottles(PET), widely use for different area, beverage, water, sparkling drinks, wine, beer…etc. Semi-auto bottle blower:need workers to operate on the machine, speed slow, small investment. Auto bottle blower:automatic operation, high level of automation, suitable for middle and high speed production plant. . |  |

Automatic Labeling machine Normally has 3 type labels: 1.Sleeve Label Shrink Machine: Most for PVC and PET material. 2.Hot Melt Labeling Machine: For OPP material 3.Adhesive Labeling Machine: For plastic/paper material |  |

Automatic Packing machine Normally has 3 types packing way: 1.PE Film Shrink Wrapping Machine: use PE Film as material. 2.Half Tray Shrink Packing Machine: use half tray and PE film as material. 3.Caron Packing Machine: use carton as material |  |

Delivery:

Sea worthy packing(Wooden case package).

1/Installation and Training

We have professional engineer for oversea installaion and training, they can speak English, and have much experience oversea work.The engineers will install the machine according to the prior layout and make it in the best condition. They will train your technicians how tomaintain the machine and treat different failures.

2/About the bottle drawing, workshop layout, and labels design

We can help customers design their own bottle shape, workshop layout and label drawings, these jobs are free charge.(Workshop need customer to provide the size of factory)

3/Quality guarantee and after-sales service

Our company provides comprehensive after-sales service and technical support,We promise that our goods are all new and did detailed test before delivery.Our machines has a one-year warranty, and once problems arise, we will supply the fastest and most professional solution.

1) Can your factory provide the whole plant from A to Z?

A: Yes, we can provide the complete plant, from bottling making plant, water purification plant, to filling packing plant.

2) Are all machinery your factory made?

A: Our factory make the water purification and filling packing plants. We do not make the bottle making machinery,

we have good quality bottle making machinery partner, and we provide to customer same long warranty time and good after service.

3) How can I know the machinery quality before I order?

A: Frist, we will invite you visiting our factory to check the machines quality, and show the machines running for you in our factory.

4)What certificates you can provide?

A: Our factory provide the CE, SGS, ISO, and accroding to some countries, we also can provide the Pvoc, Coc, Soncap...ect

5)Can your factory make the bottle drawing, workshop layout, and labels for us?

A: We can help customers design their own bottle shape, workshop layout and label drawings, these jobs are free charge.

(Workshop need customer to provide the size of factory)

6)Installation and Training Time

A: We have professional engineer for oversea installaion and training, they can speak English, and have much experience oversea work

Похожие товары

Машина для розлива газированных безалкогольных напитков, пластиковая бутылка

Индивидуальные 330 мл пластиковая бутылка сока наполнения и упаковки производственной линии

Машина для розлива газированных напитков NAVAN полностью автоматическая производственная линия

Высокоскоростная Автоматическая асептическая машина для розлива кофе для производственной линии кофе

High efficiency 2 heads 5L liquid filling machine suitable for small business

Производственная линия наполнения автоматическая пластиковая бутылка для воды 3 в 1 производственная линия наполнения жидкости

Линия по производству газированных напитков в бутылках

Новые поступления

Новинки товаров от производителей по оптовым ценам