Производители пластмассового оборудования/машина для выдувного растяжения/машина формования пластиковых бутылок

- Категория: Выдувная машина >>>

- Поставщик: Taizhou Huangyan Zhengge Plastic Machinery Co. Ltd.

Сохранить в закладки 62111820536:

Описание и отзывы

Характеристики

- Overall Appearance -

- Machine Feature -

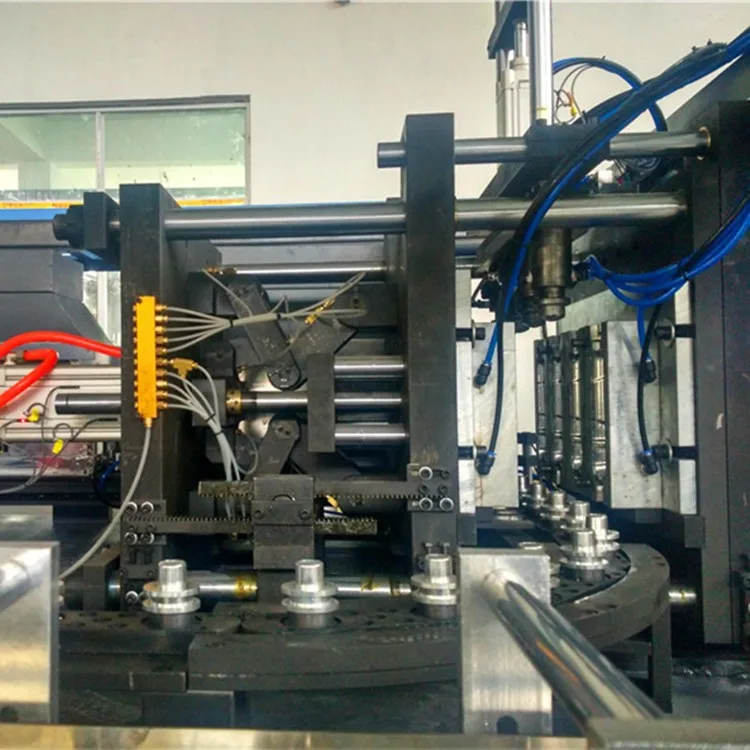

1.Fully Automatic Molding Machine perform input and ready bottle output system.

2.The Fully Automatic Molding Machine adopts overall structure of super-standard anti-vibration design, high-speed operation state of the machine will shake down to a minimum.

3. Fully Automatic Molding Machine adopts modular assembly method, greatly decrease the local amendments due to technological improvements when the machine is on processing.

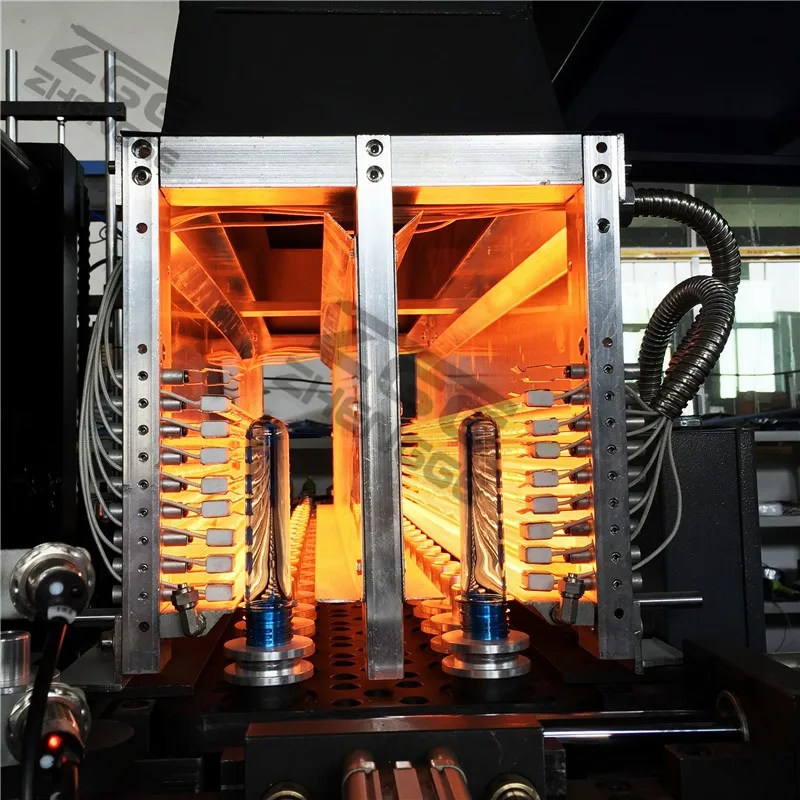

4.The structure of Fully Automatic Molding Machine oven adopt the international most advanced energy-saving technology of infrared radiation heating, temperature control with automatic negative feedback, closed-loop regulation model. Fully Automatic Molding Machine

5.Automation controlling item adopts international high-end computer system, heating, collecting and measuring perform temperature with simulation input and output module.

6.Man-machine interface displays current production situation, available for on line switching, parameter modification and production accounting, with automatic alarm, automatic fault detection and diagnose. Fully Automatic Molding Machine.

7.Storing more than 7 kinds specification for making bottle.

8.Adopt latest international air pneumatic. Fully Automatic Molding Machine .

9.In order to save air, we choose high pressure blowing exhaust recovery system, which can save energy by 10-15%.

| \t | \t | |

| \t | \t | |

| \t | \t | \t |

| \t | \t | |

| \t | \t | |

| \t | \t | |

| \t | \t | \t |

| \t | \t | |

| \t | \t | |

| \t | \t | \t |

| \t | \t | |

| \t | \t | |

| \t | \t | \t |

| \t | \t | |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

- Cooperated Brands -

We supply the whole line and best solution! Auxiliary machines we employee are all famous around the world.

PLC

A. Adopt mitsubishi brand PLC to control the machine. Easy to operate.

B. Built-in memory of the PLC saves all the sets of numbers required to produce different size bottles.

Heating system

A. Adopt energy saving infrared lamp.

B. 8 layer heating tunnel. Total 16 pieces heating lamp.

C. Each layer of lamp controlled independently,suitable for different kinds of preform.

D. Power of each lamp: 1.2Kw

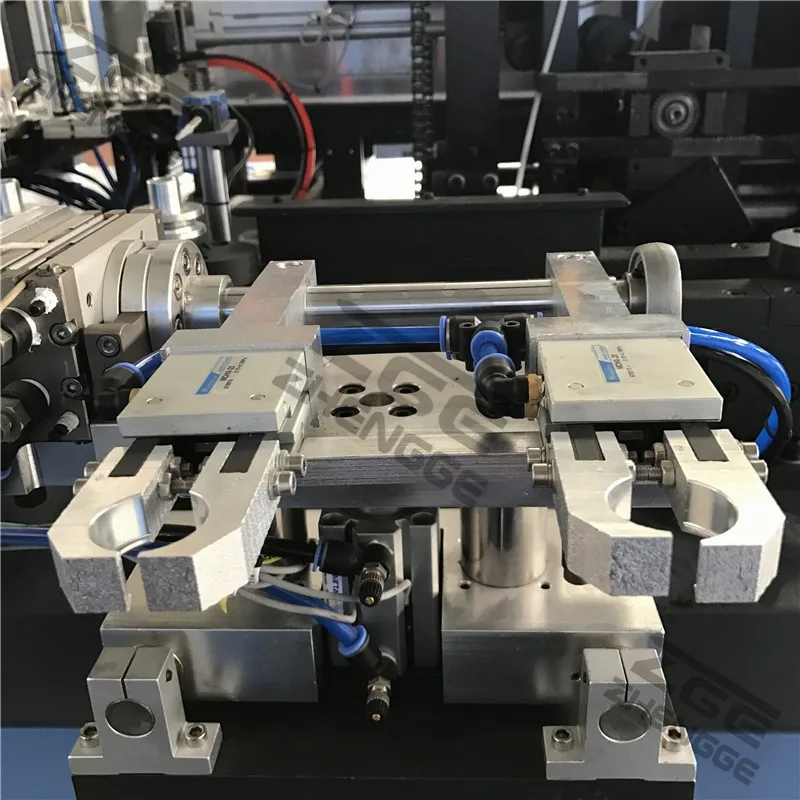

Clamping system

A. Each stretching cylinder controlled independently. Stable and reduce the failure rate.

B. The mold adopt 7075 aluminum,portable and avoid rust.

Manipulator

A.Manipulator controlled by PLC can take the finished bottle from the conveyor belt accuracy.

B.Cooperate closely,High accuracy.

C.Save labour.

Feeding Machine

A.Make the preform slide down the track and enter the heating system under its own gravity.

B.Save labour,Efficient and accurate.Without preform hurt

What Can We Do For Bottle

All bottle shape and bottle size we can do! We have a professional

engineer team.All bottle parameter can be customized by your need. We also can help you optimized bottle design and supply the best solution for you!

- Design Drawing -

- Moulds Make -

- Final Products -

Pre-Sales Service

* Welcome to visiting our Factory.

*24 hours on line answer your question.

*According customers' demands,recommending the most suitable machine.

* Take video to show real scenes as client's request.

Delivery&Package

Delivery time: 25days as usual after confirm the bottle design.

Package way:The normal package is wooden box. If export to Europe countries,the wooden box will be fumigated.If container is too tight,we will use pe film for packing or pack it according to customers special request.

After-sale Service

Installation

After equipments reached the workshop of customer, place the equipments according to plane layout we offered. We will arrange seasoned technician for equipments installation .

Quality guarantee

We promise that our goods are all new and not used. We promise that the products of this line could storage for one year without adding any aseptic.

Answering questions online

If you have any questions when use

machine,please contact us, we will help you handle in time.

- Profile -

We hold rich experiences in this line,We are trustworthy!

- Introduction -

TAIZHOU HUANGYAN ZHENGGE PLASTIC MACHINERY CO,.LTD is specialized in manufacturing bottle blowing machine and mould.we have strong technical force, excellent production equipment,advanced testing instruments and perfect management system. The product will make your enterprise have a good progress day by day. TAIZHOU HUANGYAN ZHENGGE PLASTIC MACHINERY CO,.LTD. Enjoys good reputation from regular and new customers through our excellent quality,competitive price production equipment, which attracts many customers to purchase.

- With customers -

Above Price Is Not Accurate,Only For Your Reference.

If You Need Latest Quotation,Please Contact Us!

Send your Inquiry Details in the Below , Click 'Send'Now !

Full Automatic PET Bottle Blowing Machine

Semi Automatic PET Bottle Blowing Machine

10L-25L Bottle & 5 Gallon Bottle

Semi Automatic PET Bottle Blowing Machine

Похожие товары

Машина для выдувного формования ПЭТ серии SBL -- SBL6

Дешевая машина для пластиковых бутылок/машина

ПЭТ 28 мм шеи 1000 мл 1 литр полуавтоматическая растягивающаяся пластиковая бутылка выдувная формовочная машина

Полностью автоматическая машина для вытягивания бутылок от производителя, ПЭТ воздуходувка для бутылок, цена

Высококачественная автоматическая машина для выдувания бутылок из

CE 500-1000 bph Автоматическая выдувная машина jerrycan 5

Полуавтоматическая машина для выдувного формования ПЭТ бутылок/Выдувная формовочная

Новые поступления

Новинки товаров от производителей по оптовым ценам